Ensuring Long-Term Robustness in Glycomics: Validation Strategies for Reliable Research and Biomarker Discovery

This article provides a comprehensive framework for establishing and validating the long-term robustness of glycomics methods, a critical requirement for large-scale clinical and pharmaceutical studies.

Ensuring Long-Term Robustness in Glycomics: Validation Strategies for Reliable Research and Biomarker Discovery

Abstract

This article provides a comprehensive framework for establishing and validating the long-term robustness of glycomics methods, a critical requirement for large-scale clinical and pharmaceutical studies. Tailored for researchers and drug development professionals, it covers foundational principles, high-throughput methodologies, advanced troubleshooting for multi-month studies, and rigorous comparative validation protocols. By integrating strategies from experimental design and statistical analysis of compositional data to technological advancements in mass spectrometry, this guide aims to empower scientists to generate high-quality, reproducible glycomics data capable of detecting subtle biological variations over extended periods.

The Critical Need for Robustness: Why Long-Term Stability is Non-Negotiable in Glycomics

Defining Robustness and Its Impact on Biomarker Discovery and Clinical Diagnostics

FAQs on Robustness in Biomarker Research

What does "robustness" mean in the context of biomarker discovery? In biomarker discovery, robustness refers to the consistency and reliability of a biomarker's performance. A robust biomarker should yield reproducible results across different datasets, experimental batches, statistical methods, and patient populations. It is not just about high classification accuracy in a single study, but about demonstrating that the identified biomarker or signature performs consistently in independent validation cohorts and in the face of technical variations, such as those from different sequencing platforms or sample preparation protocols [1] [2] [3].

Why is robustness a major challenge in high-throughput glycomics and glycoproteomics? Glycomics data is particularly susceptible to challenges in robustness due to:

- Technical Variance: High-throughput platforms like mass spectrometry can introduce significant batch effects and unwanted variability between experiments, which can obscure the true biological signal [3] [4].

- Low Sample-to-Variable Ratio: Omics data often involves thousands of measured molecules (e.g., genes, glycans) but a relatively small number of patient samples. This can lead to model overfitting and findings that do not generalize [1] [3].

- Biological Heterogeneity: Diseases like Congenital Disorders of Glycosylation (CDG) and cancers are clinically and genetically heterogeneous, meaning a biomarker must be effective across diverse patient sub-groups [4].

How can I improve the robustness of my biomarker selection process? Employing consensus-based machine learning strategies can significantly enhance robustness. Key practices include:

- Multiple Algorithms: Using several different classification algorithms (e.g., Random Forest, SVM, LASSO) for feature selection and taking the intersection of the most frequently selected features [1] [3].

- Resampling Techniques: Implementing rigorous cross-validation (e.g., 10-fold CV) repeatedly on the training data to ensure selected features are stable across different subsets of the data [1] [3].

- Independent Validation: Always testing the final model on a completely held-out validation dataset that was not used during any step of the feature selection or model training process [2] [3].

What is the difference between a prognostic and a predictive biomarker?

- A prognostic biomarker provides information about the patient's overall cancer outcome, such as the likelihood of disease recurrence or progression, regardless of specific therapies. It is identified through a test of association between the biomarker and the outcome [2].

- A predictive biomarker helps determine which patients are most likely to benefit from a particular treatment. It is identified through a statistical test of interaction between the treatment and the biomarker in the context of a randomized clinical trial [2].

Troubleshooting Guides

Problem: Biomarker model performs well on training data but poorly on validation data. This is a classic sign of overfitting.

- Potential Causes & Solutions:

- Cause: Data leakage, where information from the validation set inadvertently influences the training process.

- Solution: Ensure a strict separation between training and validation sets from the very beginning of the analysis. Perform all steps, including data normalization, feature selection, and model tuning, exclusively on the training data before applying the final model to the validation set [2] [3].

- Cause: The selected features are not generalizable and are too specific to the noise in the training dataset.

- Solution: Implement a more robust feature selection pipeline that uses multiple algorithms and consensus voting. For example, one study selected genes that appeared in at least 80% of models across multiple cross-validation folds [3].

Problem: Inconsistent biomarker results across different sample batches or study sites. This indicates a problem with technical variance and batch effects.

- Potential Causes & Solutions:

- Cause: Batch effects from different processing times, reagents, or personnel.

- Solution: Use bioinformatic tools designed for batch effect correction, such as ARSyN (ASCA removal of systematic noise) or the

svaR package, to remove this technical noise before analysis [5] [3]. - Cause: Differences in sample collection or preservation methods.

- Solution: Standardize experimental protocols across all sites. For glycomics, using standardized sampling methods like Dried Blood Spots (DBS) can improve consistency [4].

Problem: Identified biomarker lacks biological plausibility or clinical relevance.

- Potential Causes & Solutions:

- Cause: The model may be capturing technical artifacts rather than true biology.

- Solution: Contextualize your findings through functional enrichment analysis (e.g., GO and KEGG pathway analysis) using tools like clusterProfiler or QIAGEN Ingenuity Pathway Analysis. This helps determine if the selected biomarkers are involved in biologically relevant processes [5] [3].

Quantitative Data on Robust Methodologies

The following table summarizes validation metrics from a study on Pancreatic Ductal Adenocarcinoma (PDAC) that employed a robust machine learning pipeline. The model was trained on integrated data from multiple public repositories and validated on independent datasets [3].

Table 1: Performance Metrics of a Robust Biomarker Model for PDAC Metastasis

| Metric | Class | Score |

|---|---|---|

| Precision | Non-Metastasis | 0.85 |

| Metastasis | 0.82 | |

| Recall (Sensitivity) | Non-Metastasis | 0.80 |

| Metastasis | 0.87 | |

| F1-Score | Non-Metastasis | 0.82 |

| Metastasis | 0.84 |

Detailed Experimental Protocol for Robust Biomarker Discovery

This protocol outlines a robust, ML-based pipeline for identifying biomarker candidates from transcriptomic data, as demonstrated in PDAC research [3].

1. Data Preparation and Integration

- Data Acquisition: Pool samples from multiple public repositories (e.g., TCGA, GEO, ICGC) to maximize statistical power.

- Inclusion Criterion: Apply strict filters (e.g., primary tumour tissues, availability of clinical metastasis data, RNA-seq platform).

- Normalization & Batch Correction: Normalize data using methods like TMM from the

edgeRpackage. Correct for batch effects using a method likeARSyNfrom theMultiBaCpackage to remove technical variance.

2. Robust Feature Selection via Consensus Machine Learning

- Data Splitting: Split data into a training set (for discovery and model building) and a hold-out validation set (for final testing).

- Cross-Validation and Modeling: On the training set, perform 10-fold cross-validation. In each fold, run 100 models that combine multiple feature selection algorithms (e.g., LASSO logistic regression, Boruta, and backwards selection via

varSelRF). - Consensus Biomarker Identification: Identify robust candidate genes by selecting those that appear in a high percentage (e.g., ≥80%) of models across multiple folds.

3. Model Building and Validation

- Train Final Model: Build a classification model (e.g., Random Forest using the

rangermethod) on the entire training set using only the consensus biomarkers. - Validate: Apply the final model to the untouched validation set and evaluate performance using a comprehensive set of metrics suitable for imbalanced data (Precision, Recall, F1-score for each class).

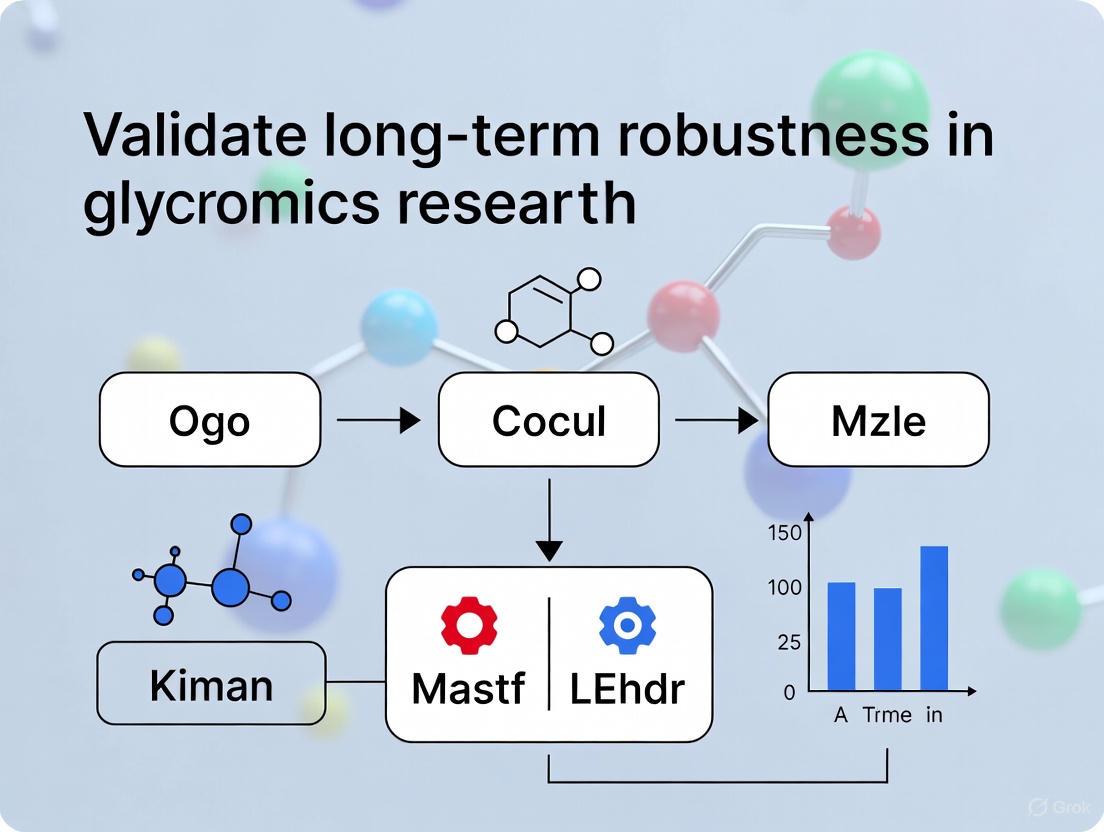

Workflow Visualization

Robust Biomarker Discovery Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Tools for Robust Glycomics and Biomarker Research

| Reagent / Tool | Function in Research |

|---|---|

| Dried Blood Spot (DBS) | A minimally invasive and cost-effective sample collection method for glycomic profiling, ideal for early diagnosis and newborn screening for CDG [4]. |

| Porous Graphitized Carbon (PGC) LC-MS | A high-resolution mass spectrometry method used for detailed glycan and glycoprotein profiling, capable of resolving isomeric glycan structures [4]. |

| Transferrin | A well-established glycoprotein marker used in biochemical screening for the majority of CDG types, particularly those affecting the N-glycosylation pathway [4]. |

| Apolipoprotein C-III (ApoCIII) | A diagnostic marker for mucin-type O-glycosylation defects, analyzed via mass spectrometry profiling [4]. |

| Next-Generation Sequencing (NGS) | Used for comprehensive genomic testing to identify genetic mutations. In biomarker testing for oncology, NGS panels are the preferred method for detecting multiple biomarkers simultaneously [6]. |

| Liquid Biopsy (ctDNA) | A blood-based test that analyzes circulating tumor DNA to find biomarker changes, useful for treatment decision-making and monitoring when a tissue biopsy is not feasible [6]. |

| QIAGEN Ingenuity Pathway Analysis (IPA) | A bioinformatics software used for the functional enrichment and pathway analysis of biomarker candidates to understand their biological context and relevance [3]. |

In glycomics research, the structural diversity of glycans and the complexity of their analysis make experimental consistency paramount. Method drift—the subtle, unplanned variation in experimental parameters over time—is a significant yet often overlooked source of error that can systematically bias results, leading to irreproducible findings and spurious biological conclusions. This technical support resource outlines the major sources of this instability, provides protocols for its detection and prevention, and offers solutions to common challenges, all within the critical context of long-term robustness validation.

Troubleshooting Guides

Guide 1: Addressing Poor Chromatographic Reproducibility

Symptoms: Shifting retention times, changing peak shapes, or altered resolution between sample runs.

- Potential Cause 1: Degradation of the LC column or use of different column batches.

- Solution: As part of robustness testing, establish system suitability tests with a standard glycan mix. If performance drifts outside accepted limits, replace the column. For long-term studies, pre-qualify and reserve columns from the same manufacturing lot [7].

- Potential Cause 2: Uncontrolled fluctuations in mobile phase pH, buffer concentration, or temperature.

- Solution: Implement strict standard operating procedures (SOPs) for mobile phase preparation. Use pH meters with regular calibration and control column temperature using a dedicated oven. A robustness study should define acceptable operating ranges for these parameters (e.g., pH ±0.2 units, temperature ±2°C) [7] [8].

Guide 2: Troubleshooting Inconsistent Glycopeptide Enrichment

Symptoms: High variability in glycopeptide yields and signal intensities, leading to non-reproducible quantitation.

- Potential Cause 1: Inconsistent binding conditions during lectin-based enrichment.

- Solution: Pre-qualify lectin lots for consistent performance. Precisely control incubation times, temperatures, and buffer compositions as defined during method validation. Automated liquid handlers can improve reproducibility [9].

- Potential Cause 2: Loss of glycopeptides during washing or elution steps.

- Solution: Use internal standards (e.g., stable isotope-labeled glycopeptides) to monitor and correct for recovery losses. Optimize and fix elution conditions (e.g., specific sugar concentrations, low pH) during method development and do not deviate [9].

Guide 3: Correcting for Batch Effects in MS-Based Quantitation

Symptoms: Systematic differences in glycan abundances between experimental batches, making direct comparisons invalid.

- Potential Cause 1: Drift in mass spectrometer calibration or detector sensitivity over time.

- Solution: Institute a regular calibration schedule using standard compounds. Analyze a quality control (QC) sample—a pooled mixture from all samples—at the beginning, throughout, and at the end of each batch. Use QC data to correct for batch effects using statistical algorithms [10].

- Potential Cause 2: Variations in sample preparation between batches or different analysts.

- Solution: Use a randomized block design for processing samples across batches to avoid confounding biological groups with processing batches. Where possible, a single analyst should process an entire study set, or else a rigorous robustness study must demonstrate intermediate precision (ruggedness) across multiple analysts and days [7] [11].

Frequently Asked Questions (FAQs)

FAQ 1: What is the fundamental difference between robustness and ruggedness?

- Answer: Robustness is the measure of a method's capacity to remain unaffected by small, deliberate variations in method parameters (e.g., mobile phase pH, temperature), as listed in its procedure. Ruggedness (also referred to as intermediate precision) refers to the degree of reproducibility of results under a variety of normal, expected conditions, such as different laboratories, analysts, instruments, and days [7].

FAQ 2: Why is glycomics particularly susceptible to errors from method drift?

- Answer: Glycans possess vast structural complexity, including numerous isomers that differ only in monosaccharide linkages or positions. Method drift in separation or ionization efficiency can preferentially affect some isomers over others, dramatically altering perceived relative abundances and leading to incorrect biological interpretations [12] [13] [14].

FAQ 3: How can I proactively design my method to be more robust?

- Answer: During method development, employ structured experimental designs like Design of Experiments (DoE). Screening designs such as Plackett-Burman or fractional factorial can efficiently identify which method parameters (e.g., pH, temperature, flow rate) have the most significant impact on your results, allowing you to either control them tightly or define a wide, safe operating range [7] [8].

FAQ 4: My lab wants to adopt a new, standardized protocol. Will this eliminate bias and drift?

- Answer: Standardization reduces variation but does not eliminate inherent methodological bias. A standardized protocol will consistently apply the same bias, but unmeasured technical variability can still introduce drift. Furthermore, the protocol itself may be biased toward detecting certain glycans over others. The use of calibration controls is necessary to move toward true quantitative accuracy [10].

FAQ 5: What is the most common statistical flaw that leads to irreproducible results?

- Answer: A major flaw is the reliance on small sample sizes and small effect sizes, which increases the likelihood that a reported finding is false. Furthermore, failure to control for known sources of variability (like "cage effects" in animal studies or processing batches in omics) through proper experimental design completely confounds results and makes valid statistical analysis impossible [15] [11].

Quantitative Impact of Methodological Variations

The following table summarizes how specific technical variations can quantitatively impact glycomic data, leading to potential false conclusions.

Table 1: Consequences of Methodological Drift in Glycomics Workflows

| Analytical Phase | Type of Method Drift | Potential Impact on Data | Risk of Spurious Conclusion |

|---|---|---|---|

| Sample Preparation | Variation in protein extraction efficiency or enzymatic release time [9]. | Altered representation of specific glycan classes (e.g., under-representation of sialylated glycans). | Misidentification of a true abundance change as a disease biomarker. |

| LC Separation | Drift in mobile phase pH or column temperature [7]. | Altered retention times and co-elution of isomeric glycans, changing their measured ratios. | Incorrect assignment of isomeric structures and their biological roles. |

| MS Analysis | Gradual contamination of ion source or calibration drift [10]. | Reduced sensitivity/signal for low-abundance glycans; inaccurate mass assignment. | Failure to detect a critical, low-abundance glycoform; misidentification of compositions. |

| Data Analysis | Inconsistent software parameters or database versions [14]. | Variable identification rates and false-positive/negative assignments between studies. | Inflated or underestimated reports of glycosylation changes between sample cohorts. |

Experimental Protocols for Robustness Validation

Protocol 1: Robustness Testing Using a Full Factorial Design

This protocol assesses the simultaneous effect of multiple critical method parameters.

- Identify Factors: Select 3-4 critical parameters to evaluate (e.g., Mobile Phase pH, Column Temperature, Flow Rate, Gradient Time).

- Define Ranges: Set a nominal value and a realistic, small variation for each (e.g., pH = 5.0 ± 0.2; Temperature = 40°C ± 3°C).

- Design Experiment: Use a full factorial design (2k), which for 3 factors requires 8 experimental runs. Include center point replicates to check for curvature.

- Execute Runs: Analyze a standard glycan mixture under each of the 8 defined conditions in a randomized order.

- Measure Responses: For each run, record key performance metrics: Retention Time, Peak Area, and Resolution between critical isomer pairs.

- Statistical Analysis: Perform Analysis of Variance (ANOVA) to determine which parameters significantly affect each response. Establish system suitability limits based on the results [7].

Protocol 2: Monitoring Long-Term Reproducibility with Quality Control Samples

This protocol establishes a system for continuous monitoring of method stability.

- Create QC Pool: Prepare a large, homogeneous pool of a representative sample (e.g., pooled plasma, a standard glycoprotein digest). Aliquot and store at -80°C.

- Establish a Baseline: Analyze the QC sample 5-10 times to establish baseline mean and standard deviation for key analytes (e.g., abundance of a major bi-antennary glycan, ratio of two isomers).

- Intermittent Analysis: With each batch of experimental samples, analyze the QC sample. Plot the results on a control chart with upper and lower control limits (e.g., ±3 standard deviations).

- Correct for Drift: If the QC data shows a systematic drift, use statistical models to correct the experimental data from that batch, ensuring comparability across the entire study [10].

Workflow Visualization

Consequences of Method Drift and Path to Robustness

Research Reagent Solutions

Table 2: Essential Materials for Robust Glycomics Workflows

| Item | Function in Workflow | Considerations for Robustness |

|---|---|---|

| Standard Glycan Library | Provides reference retention times, mass, and CCS values for unambiguous identification [12] [14]. | Use to establish system suitability tests; critical for detecting drift in separation and MS performance. |

| Stable Isotope-Labeled Glycopeptides | Serves as internal standards for quantitative precision, correcting for variations in sample prep and MS response [9]. | Choose standards that cover different glycan classes (e.g., high-mannose, sialylated) to monitor broad performance. |

| Porous Graphitic Carbon (PGC) Column | Separates glycan isomers based on their planar interaction with the graphite surface [12] [14]. | Monitor performance with isomer standards; batch-to-batch consistency is critical. |

| Lectin Enrichment Kits (e.g., Con A, SNA) | Isolate specific sub-populations of glycans/glycopeptides (e.g., fucosylated, sialylated) from complex mixtures [9]. | Pre-quality lectin lots; tightly control binding/washing conditions as defined in robustness studies. |

| Quality Control (QC) Sample Pool | A homogeneous sample analyzed repeatedly to monitor system stability and correct for batch effects over time [10]. | Should be a representative, complex matrix (e.g., pooled serum) and stored in single-use aliquots. |

Troubleshooting Guides

FAQ: Addressing Sensitivity and Robustness in High-Throughput Glycomics

1. How can I ensure my high-throughput glycomics method is sensitive enough to detect small biological variations over long-term studies? High-throughput methodologies must be sensitive, robust, and stable over periods of several months to reliably detect small biological variations in glycosylation. A key strategy is to employ a comprehensive validation protocol that assesses long-term robustness. This includes determining between-day and between-analyst variation by having multiple analysts prepare and analyze the same set of samples over several different days. The results should be evaluated using statistical models, such as linear mixed models, to quantify the variance introduced by these factors. A method is considered robust if the variation introduced by the analyst or day is significantly smaller than the actual biological variation you intend to measure [16] [17].

2. What are the critical steps in sample preparation for obtaining high-quality, reproducible glycomics data? Sample preparation is a major source of variance. Critical steps that require meticulous optimization include:

- IgG Isolation: Use freshly prepared and filtered buffers. The use of 96-well plates and a vacuum manifold standardizes this step for high-throughput processing [17].

- N-Glycan Release: The enzyme peptide-N-glycosidase F (PNGaseF) is commonly used to release N-linked glycans. The efficiency of this step is critical [18].

- Fluorescent Labeling: The labeling of glycans with a fluorophore, such as 2-aminobenzamide (2-AB), must be highly controlled. After labeling, excess dye must be thoroughly removed to ensure accurate chromatographic analysis [17]. To identify which steps have the most significant impact on your results, employ an experimental Plackett-Burman screening design during method development. This approach efficiently tests the main effects of multiple variables (e.g., incubation times, temperatures, reagent volumes) without requiring a full factorial design, which would be infeasible [16] [17].

3. My glycomics data shows high variability. How can I determine if the source is technical or biological? Performing an "analysis of sources of variation" is a powerful experimental approach to answer this question. This involves creating pooled sample quality control (QC) pools from the biological samples under study. These QC pools are then analyzed multiple times throughout the experiment, both within the same batch (e.g., on the same 96-well plate) and across different batches (e.g., on different days or by different analysts). By measuring the variance of specific glycan peaks within the QC pools and comparing it to the variance across all individual biological samples, you can quantify the technical variation introduced by the sample preparation and measurement process. If the technical variance is a large component of the total variance, further optimization of the method is required before meaningful biological conclusions can be drawn [17].

4. Why is proper experimental design crucial for high-throughput glycomics, and how can I avoid batch effects? Large-scale studies are typically processed in batches (e.g., 96-well plates), which can introduce batch effects due to minor differences in reagents, equipment, or analyst performance. A proper experimental design is the first prerequisite for high-quality data. To minimize bias:

- Randomize Samples: Do not process all samples from one group (e.g., control) on one day and another group (e.g., disease) on another. Instead, randomize the assignment of samples from all groups across all plates and runs.

- Include QC Pools: As mentioned above, include a QC pool sample in every batch to monitor and correct for technical drift over time.

- Balance Confounding Factors: Account for known confounding factors like age and sex by ensuring they are balanced across your experimental batches [17].

5. What are the common pitfalls in statistical analysis of comparative glycomics data, and how can they be avoided? A major and often overlooked pitfall is that glycomics data is fundamentally compositional. This means that measured glycans are parts of a whole, typically expressed as relative abundances. Applying traditional statistical tests (e.g., t-tests) directly to these relative abundances can generate spurious correlations and high false-positive rates, as an increase in one glycan mathematically forces a decrease in others. To avoid this, a Compositional Data Analysis (CoDA) framework must be applied. This involves transforming the data using methods like the center log-ratio (CLR) or additive log-ratio (ALR) transformation, which respect the simplex geometry of the data. Using CoDA-based differential expression analysis controls false-positive rates while maintaining excellent sensitivity to detect true biological changes [19].

Troubleshooting Common Technical Issues

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| High background noise in UPLC chromatograms | Inefficient removal of excess fluorescent dye after labeling. | Optimize the clean-up step using solid-phase extraction plates (e.g., HILIC µElution plates). Ensure washing buffers have the correct acetonitrile concentration [17]. |

| Poor chromatographic peak shape or resolution | Degraded UPLC column; incorrect mobile phase pH or preparation. | Flush and re-condition the HILIC column according to manufacturer guidelines. Prepare fresh mobile phase buffers weekly and ensure they are filtered [17]. |

| Low signal intensity across all samples | Inefficient glycan release or labeling; instrument detector issues. | Check the activity of the PNGaseF enzyme and the freshness of the labeling reagent. Confirm the stability of the light source and settings on the fluorescence (FLR) detector [17]. |

| Inconsistent results between sample batches | Batch effect from reagent lot changes or analyst drift. | Implement a rigorous randomization strategy. Include inter-batch QC pools to monitor performance. Use experimental designs like Plackett-Burman to identify critical factors for re-optimization [16] [17]. |

| Statistical results showing spurious glycan "decreases" | Treating relative abundance data as absolute, ignoring compositional nature. | Re-analyze data using a Compositional Data Analysis (CoDA) workflow with CLR or ALR transformations, available in packages like the glycowork Python library [19]. |

Experimental Protocols for Validation

Protocol 1: Determining Between-Day and Between-Analyst Variation

Purpose: To validate the long-term robustness of a high-throughput glycomics method by quantifying variance introduced by time and different operators.

Methodology:

- Sample Preparation: Select a minimum of 5-8 individual biological samples that represent the expected biological range of your study.

- Replicate Design: Have at least two different analysts prepare and analyze these same samples in replicate over a period of several different days. The design should ensure that each sample is processed multiple times by each analyst across different days.

- Data Collection: Process all samples using the standard high-throughput workflow (e.g., IgG isolation, glycan release, labeling, clean-up, and HILIC-UPLC analysis).

- Statistical Analysis: Analyze the resulting glycan abundance data using a linear mixed model. The model should include analyst and day as random effects. The variance components estimated for these effects will quantify their contribution to the total variance. A robust method will have variance components for analyst and day that are significantly smaller than the biological variance between the individual samples [17].

Purpose: To identify which steps in a sample preparation protocol contribute the most technical variance.

Methodology:

- Create QC Pools: Generate a pooled sample by combining small aliquots of all individual biological samples in your study. This pool should be homogenous and large enough to be analyzed multiple times.

- Staggered Replicate Analysis: Divide the QC pool into multiple aliquots. These aliquots should be analyzed in a staggered design:

- Within-Batch Variance: Analyze several replicates of the QC pool on the same 96-well plate.

- Between-Batch Variance: Analyze replicates of the QC pool across different plates and on different days.

- Variance Calculation: For each measured glycan, calculate the variance of its abundance within the same batch and between different batches.

- Interpretation: Steps that contribute high variance will result in a large between-batch variance component. This pinpoints areas for further method optimization to improve overall precision and reproducibility [17].

Workflow and Relationship Diagrams

Diagram 1: High-Throughput Glycomics Validation Workflow

This diagram outlines the core process for developing and validating a robust high-throughput glycomics method.

Diagram 2: Compositional Data Analysis Logic

This chart illustrates the correct statistical pathway for analyzing comparative glycomics data to avoid false discoveries.

Research Reagent Solutions

The following table details key materials and reagents essential for a high-throughput glycomics workflow, as derived from the cited protocols.

| Item | Function in Experiment |

|---|---|

| CIM Protein G 96-well Plate | High-throughput affinity isolation of IgG from plasma or serum samples [17]. |

| Peptide-N-Glycosidase F (PNGaseF) | Enzyme that releases N-linked glycans from glycoproteins for subsequent analysis [18]. |

| 2-Aminobenzamide (2-AB) | Fluorescent dye used to label released glycans, enabling detection by UPLC-FLR [17]. |

| HILIC µElution Plate | A 96-well solid-phase extraction plate for efficient clean-up and removal of excess 2-AB dye after the labeling reaction [17]. |

| Waters BEH Glycan UPLC Column | Stationary phase for Hydrophilic Interaction Liquid Chromatography (HILIC) separation of fluorescently labeled glycans [17]. |

| Inter-Batch Quality Control (QC) Pool | A homogenized pool of sample aliquots used to monitor technical performance and correct for drift across all batches and over time [17] [19]. |

Frequently Asked Questions (FAQs)

FAQ 1: What are the most critical sources of variation to control in a high-throughput glycomics study? The most critical sources of variation are batch effects, analyst performance, and reagent quality. Large-scale studies are typically processed in batches (e.g., 96-well plates), and minor differences in buffers, solutions, filters, or analyst technique can introduce significant batch effects [17]. Furthermore, the stability of reagents over the long periods of time required to analyze thousands of samples is crucial for detecting small biological variations [16] [17].

FAQ 2: How can we statistically account for the compositional nature of glycomics data? Glycomics data, expressed as relative abundances, are fundamentally compositional. An increase in one glycan's relative abundance mathematically necessitates a decrease in others, which can lead to spurious correlations and high false-positive rates if analyzed with traditional statistics [19]. A robust approach involves using compositional data analysis (CoDA) frameworks with center log-ratio (CLR) or additive log-ratio (ALR) transformations. These methods respect the data's relative scale and, when combined with a scale uncertainty model, control false-positive rates while maintaining high sensitivity [19] [20].

FAQ 3: What is a best-practice protocol for validating the long-term robustness of a glycomics method? A comprehensive validation should assess both between-day and between-analyst variation over several days. For HILIC-UPLC analysis of IgG N-glycans, this involves:

- Replicate Analysis: Preparing and analyzing 5-8 replicates over multiple days [17].

- Robustness Testing: Using experimental designs like the Plackett-Burman screening design during method development to identify critical factors that influence results [17].

- Precision Measurement: Quantifying the coefficient of variation (CV) for glycan peaks. High-precision methods can achieve an average CV of around 10% [21].

FAQ 4: Our study spans years. How stable is the plasma N-glycome in individuals over time? Research shows that an individual's plasma N-glycome is remarkably stable over periods of several years. This low intra-individual variability over time makes longitudinal studies highly powerful, as small but significant changes related to lifestyle, environmental factors, or disease progression can be detected against a stable baseline [22].

Troubleshooting Guides

Problem: High variation between sample batches.

- Potential Cause: Batch effects from differences in reagent lots, sample plate types, or environmental conditions.

- Solutions:

- Experimental Design: Plan for randomization of samples across batches to avoid confounding biological groups with processing batches [17].

- Batch Correction: Apply statistical batch correction methods, such as the ComBat algorithm from the 'sva' R package, to the normalized data after log-transformation, using the sample plate as a batch covariate [23].

- Reagent Management: Where possible, use a single, large lot of critical reagents for the entire study [17].

Problem: Inconsistent results when multiple analysts perform the sample preparation.

- Potential Cause: Lack of standardization in manual steps of the protocol.

- Solutions:

- SOPs and Training: Develop and validate a detailed, step-by-step Standard Operating Procedure (SOP). Ensure all analysts are trained to proficiency and demonstrate competence in the method [17].

- Between-Analyst Validation: Formally include between-analyst variation as a parameter in your method validation protocol to quantify and control this source of error [17].

Problem: Data shows spurious "decreases" in glycan abundances when others increase.

- Potential Cause: The data is being analyzed as independent values, ignoring its compositional nature.

- Solutions:

- Data Transformation: Immediately transform relative abundance data using CLR or ALR transformations before applying any downstream statistical tests [19].

- Specialized Tools: Use software packages designed for glycomics, like the glycowork Python package, which has built-in CoDA workflows for differential expression analysis [20].

Experimental Validation Data

Table 1: Key Parameters for Robustness Validation in Glycomics (based on HILIC-UPLC)

| Parameter | Validation Approach | Target Performance | Citation |

|---|---|---|---|

| Between-Day Precision | Analysis of 5-8 replicates over several days. | Low CV for all major glycan peaks. | [17] |

| Between-Analyst Precision | Different analysts prepare and analyze replicate samples. | Consistent results, with no systematic bias. | [17] |

| Long-Term Robustness | Analysis of hundreds to thousands of samples over months. | Method stability over time; ability to detect biological variation. | [16] [17] |

| Linearity | Analysis across a wide concentration gradient (e.g., 75-fold). | R² value > 0.99. | [21] |

| Repeatability | Six replicate analyses on a single day. | Average CV ~10%. | [21] |

Table 2: Example Quantitative Performance of a High-Throughput MALDI-TOF-MS Method

| Performance Metric | Result | Details |

|---|---|---|

| Repeatability (CV) | 6.44% - 12.73% (Avg. 10.41%) | 6 replicates, single day [21] |

| Intermediate Precision (CV) | 8.93% - 12.83% (Avg. 10.78%) | 12 samples over 3 days [21] |

| Linearity (R²) | > 0.9818 (Avg. 0.9937) | Across a 75-fold concentration range [21] |

Detailed Experimental Protocols

Protocol 1: Method Validation for Long-Term Robustness

This protocol is adapted from Trbojević-Akmačić et al. for validating IgG N-glycan analysis by HILIC-UPLC [17].

- Sample Preparation:

- Isolate IgG from plasma or serum using a Protein G 96-well plate and a vacuum manifold.

- Release N-glycans using the enzyme PNGase F.

- Label released glycans with a fluorescent tag (2-AB).

- Purify labeled glycans using solid-phase extraction (SPE) via HILIC in a 96-well plate format.

- UPLC Analysis:

- Separate 2-AB-labeled N-glycans on a BEH Glycan chromatography column using a defined gradient of ammonium formate and acetonitrile.

- Detect glycans using a fluorescence detector (FLR).

- Validation Design:

- Have at least two different analysts prepare and analyze a set of 5-8 replicate samples over the course of 3-5 separate days.

- Randomize the order of samples across all runs.

- Data Analysis:

- Integrate chromatograms to obtain peak areas for each glycan structure (GP).

- Normalize data by converting peak areas to relative percentages (% of total area).

- Calculate the Coefficient of Variation (CV) for each glycan peak across the within-day and between-day analyses to quantify precision.

Protocol 2: A High-Throughput Screening Workflow using MALDI-TOF-MS

This protocol summarizes a recent high-throughput method for biologics development [21].

- Internal Standard Preparation:

- Create a full glycome internal standard library by performing a one-step reductive isotope labeling on a pooled glycan sample. This generates internal standards with a known mass shift (+3 Da).

- Sample Preparation in 96-Well Plates:

- Release N-glycans from therapeutic proteins (e.g., trastuzumab) in a 96-well plate.

- Mix the released native glycans from the sample with the prepared internal standard library.

- Perform purification and enrichment using Sepharose HILIC SPE in the 96-well plate format, enabling automation on a liquid handling robot.

- Rapid MS Analysis:

- Analyze the purified glycans using MALDI-TOF-MS, which can process hundreds of samples within minutes.

- Quantitative Data Processing:

- Quantify each glycan by taking the ratio of its signal intensity to that of its corresponding internal standard. This internal standard approach corrects for preparation and ionization variability, improving quantitative accuracy compared to using relative abundances alone [21].

Workflow and Relationship Diagrams

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Robust Glycomics

| Item | Function | Application Note |

|---|---|---|

| PNGase F | Enzyme that releases N-linked glycans from glycoproteins for analysis. | Critical for sample prep; use a consistent, high-activity lot [23] [18]. |

| 2-AB (2-Aminobenzamide) | Fluorescent dye for labeling released glycans for detection in UPLC/HLIC-FLR. | Enables sensitive detection; stability of the dye solution should be monitored [23] [17]. |

| BEH Glycan UPLC Column | Stationary phase for hydrophilic interaction liquid chromatography (HILIC) separation of glycans. | Column performance and longevity are key for reproducible retention times [17]. |

| Sepharose CL-4B HILIC Plates | 96-well solid-phase extraction plates for high-throughput glycan purification. | Enables automation and increases throughput compared to manual tips [21]. |

| Full Glycome Internal Standard | Isotope-labeled glycan library for precise quantification in mass spectrometry. | Corrects for variability in sample prep and ionization; improves accuracy [21]. |

Building a Robust Glycomics Workflow: From Sample Preparation to High-Throughput Analysis

Optimized Protocols for IgG Isolation and N-Glycan Release, Fluorescent Labeling, and Purification

Frequently Asked Questions (FAQs)

Q1: What are the primary methods for isolating IgG from complex samples like plasma or serum? Protein G-based affinity purification is a highly effective method for isolating IgG. A robust protocol involves using a 96-well protein G monolithic plate, which allows for high-throughput, convective mass transport and rapid processing of samples with high dynamic binding capacity. This method is particularly suited for large-scale studies, such as population glycomics [24].

Q2: Which enzyme is most commonly used for releasing N-glycans from glycoproteins like IgG? Peptide-N-Glycanase F (PNGase F) is the most frequently used enzyme for the release of N-glycans from therapeutic proteins and antibodies. It hydrolyzes nearly all types of N-glycans, except those with core α1-3 linked fucose (common in plants and insects). Recent advancements include "rapid release" protocols that shorten this incubation time [25] [26].

Q3: Why is a labeling step critical for N-glycan analysis? Released N-glycans lack intrinsic chromophores or fluorophores, making direct detection challenging. Fluorescent labeling serves two main purposes:

- It enables highly sensitive detection, especially for techniques like Hydrophilic Interaction Liquid Chromatography with fluorescence detection (HILIC-FLD).

- It can improve ionization efficiency and signal intensity for Mass Spectrometry (MS) analysis [25].

Q4: My fluorescence signal is weak after labeling. What could be the cause? Low signal can result from several factors [27] [28]:

- Insufficient dye incorporation: The degree of labeling (DOL) may be too low. Optimize the molar ratio of labeling reagent to glycan.

- Dye-dye quenching: An excessively high DOL can cause self-quenching of the fluorophore.

- Suboptimal conjugation: The fluorophore may be attached near a microenvironment that quenches fluorescence, such as aromatic amino acids.

- Antibody concentration too low: Titrate your primary antibody concentration if using immunofluorescence detection.

Q5: I am observing high background in my analysis. How can I reduce it? High background can be due to [28]:

- Sample autofluorescence: This is common in tissue sections. Use an unstained control to assess the level. Consider using autofluorescence quenchers or switching to red/far-red fluorescent dyes, as autofluorescence is higher in blue wavelengths.

- Incomplete cleanup: Ensure thorough removal of excess labeling reagents and salts through sufficient washing steps using appropriate clean-up methods like solid-phase extraction [26].

- Antibody cross-reactivity: For indirect staining, use highly cross-adsorbed secondary antibodies and include staining controls with the secondary antibody alone.

Q6: Are there alternatives to traditional PNGase F release? Yes, chemical release methods are available. Hydrazinolysis can release both N- and O-linked glycans but requires strict control of reaction conditions [26]. A more recent development is the Oxidative Release of Natural Glycans (ORNG), which uses household bleach (e.g., calcium hypochlorite) for rapid release (e.g., 1 minute). ORNG is efficient, cost-effective, and suitable for large-scale studies, showing comparable results to PNGase F for human serum profiling [29].

Troubleshooting Guides

Table 1: Troubleshooting IgG Isolation and N-Glycan Analysis

| Problem | Potential Cause | Suggested Solution |

|---|---|---|

| Low IgG Yield | Overloaded affinity plate; insufficient binding time | Reduce sample load; ensure adequate incubation time with the protein G monolithic plate [24] |

| Incomplete N-glycan Release | Presence of PNGase F inhibitors; core α1-3 fucosylation | Denature the glycoprotein prior to enzymatic digestion; for plant/insect samples, consider alternative enzymes or chemical release (ORNG) [25] [29] |

| Poor Labeling Efficiency | Low reagent-to-glycan ratio; impure glycan sample; reducing agent depleted | Increase the concentration of the labeling agent; ensure glycans are cleaned up before labeling; use fresh reducing agent (e.g., sodium cyanoborohydride) [25] [27] |

| High Background in Chromatography | Incomplete removal of excess dye or salts | Optimize clean-up steps using hydrophilic interaction or graphitized carbon cartridges (e.g., LudgerClean EB10) [26] |

| Altered Antigen Binding (for labeled Abs) | Label attached to lysines in the antigen-binding site | Use site-specific labeling kits (e.g., SiteClick) that target the Fc region, leaving the antigen-binding site unmodified [27] |

Table 2: Quantitative Performance of Key Techniques

| Technique / Reagent | Typical Incubation Time | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Protein G Monolith | High-throughput (96-well) | Fast processing, high binding capacity [24] | Specific to IgG isolation |

| PNGase F (Classical) | Several hours to overnight | High specificity, leaves core intact [25] | Ineffective for core α1-3 fucosylated N-glycans [26] |

| PNGase F (Rapid) | Minutes | Drastically reduced processing time [25] | May require optimization for new sample types |

| ORNG (Chemical Release) | ~1 minute | Very fast, cost-effective, works on resistant glycans [29] | Can produce side products; reaction requires quenching [29] |

| 2-Aminobenzamide (2-AB) | Several hours | Common, well-characterized, fluorescent [24] | Requires cleanup post-labeling [26] |

Detailed Experimental Protocols

Protocol 1: High-Throughput IgG Isolation Using Protein G Monolithic Plate

This protocol is adapted from a large-scale population study [24].

- Plate Preparation: Condition the 96-well protein G monolithic plate with phosphate-buffered saline (PBS).

- Sample Loading: Dilute plasma or serum samples in PBS and apply to the wells.

- Binding: Incubate with gentle shaking to allow IgG to bind to the protein G ligand via the Fc region. The convective flow in monoliths allows for fast binding.

- Washing: Wash the wells extensively with PBS to remove non-specifically bound proteins and contaminants.

- Elution: Elute the purified IgG using a low-pH buffer (e.g., 0.1 M glycine-HCl, pH 2.5-3.0). Immediately neutralize the eluate with a Tris buffer, pH 8.0-9.0.

- Desalting/Buffer Exchange: Transfer the IgG to a suitable buffer (e.g., 50 mM ammonium bicarbonate) for downstream enzymatic digestion, using spin filters or dialysis.

Protocol 2: Enzymatic N-Glycan Release with PNGase F

- Denaturation: Denature the purified IgG (in 50 mM ammonium bicarbonate) by heating at 95°C for 3-5 minutes in the presence of 0.1% w/v SDS. Allow to cool.

- Neutralization: Add a non-ionic detergent like NP-40 to a final concentration of 1% to neutralize the SDS.

- Enzymatic Digestion: Add PNGase F enzyme (e.g., 1-5 mU per 100 μg of protein) and incubate at 37°C for several hours or overnight. Rapid release kits are available that reduce this time to minutes [25].

- Release Confirmation (Optional): The release of glycans can be confirmed by a gel shift assay (SDS-PAGE) of the deglycosylated protein.

- Glycan Separation: Released glycans can be separated from the protein/peptide backbone using solid-phase extraction (e.g., C18 or PGC cartridges) or by precipitating the protein with cold ethanol.

Protocol 3: Rapid Chemical N-Glycan Release via ORNG

This protocol uses calcium hypochlorite for rapid release [29].

- Sample Preparation: Prepare an aqueous solution of your glycoprotein at ~5 mg/mL.

- Oxidant Preparation: Prepare a fresh solution of Ca(ClO)₂ at 10 mg/mL in water. Centrifuge briefly to remove insolubles.

- Reaction: Mix 10 μL of glycoprotein with 5 μL of Ca(ClO)₂ solution. Vortex at room temperature for 1 minute.

- Quenching: Add 5 μL of a sodium sulfite (Na₂SO₃) solution (100 mg/mL) to quench the reaction.

- Purification: The released glycans can now be directly labeled or purified for analysis using methods like solid-phase extraction on a Hypercarb plate [29].

Protocol 4: Fluorescent Labeling of N-Glycans with 2-Aminobenzamide (2-AB)

This is a standard protocol using reductive amination [24].

- Preparation: Ensure the glycan sample is dry in a tube.

- Labeling Mix: Prepare a labeling solution containing 2-AB in a mixture of dimethyl sulfoxide (DMSO) and acetic acid, with sodium cyanoborohydride as a reducing agent.

- Reaction: Add the labeling mix to the dried glycans and incubate at 65°C for 2-3 hours.

- Cleanup: Purify the labeled glycans from excess dye using hydrophilic interaction solid-phase extraction cartridges (e.g., LudgerClean S) [26]. The glycans bind to the cartridge in a high-ACN solvent, and after washing, are eluted with water.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Kits for IgG Glycomics

| Item | Function | Example Product / Note |

|---|---|---|

| Protein G Monolithic Plate | High-throughput affinity purification of IgG from biofluids [24] | Custom 96-well plates (BIA Separations) |

| PNGase F Enzyme | Enzymatic release of N-glycans from the protein backbone [25] | Various suppliers (e.g., LudgerZyme E-PNG-01) |

| Hydrazine Kit | Chemical release of both N- and O-linked glycans [26] | Ludger Hydrazinolysis kit (LL-HYDRAZ-A2) |

| 2-Aminobenzamide (2-AB) | Fluorescent dye for labeling glycans via reductive amination for HILIC-FLD analysis [24] | Common label used in glycomics kits |

| Solid-Phase Extraction Cartridges | Cleanup of labeled glycans to remove excess dye and salts [26] | LudgerClean S (HILIC), LudgerClean EB10 (PGC) |

| Porous Graphitic Carbon (PGC) LC Columns | High-resolution LC-MS separation of glycan isomers [30] | Essential for advanced structural analysis |

Workflow and Pathway Diagrams

IgG N-Glycan Analysis Workflow diagram illustrates the four major stages of the process, from sample preparation to data analysis, highlighting key steps and technological choices at each phase.

Troubleshooting Low Fluorescence diagram provides a logical flow for diagnosing and resolving the common issue of weak fluorescence signal after the glycan labeling process.

Troubleshooting Guides and FAQs

Frequently Asked Questions

Q1: Why are my retention times inconsistent between runs? Inconsistent retention times are often due to inadequate column conditioning or equilibration. The HILIC mechanism relies on a stable water layer on the polar stationary phase, which requires proper establishment before analysis and between injections [31].

- Solution: For isocratic methods, condition a new column with at least 50 column volumes of the mobile phase. Between injections, equilibrate with a minimum of 10 column volumes. For gradient methods, perform at least 10 blank injections running the full time program for initial conditioning [31].

Q2: My analytes are not eluting, or I see poor peak shapes. What could be wrong? This is frequently caused by a mismatch between your sample injection solvent and the initial mobile phase conditions [31].

- Solution: Ensure the injection solvent closely matches the initial mobile phase's high organic content (typically >70% acetonitrile). Avoid dissolving samples in 100% aqueous solvent. If you must use a strong solvent like DMSO, keep the final concentration in the sample vial below 20% [31] [32].

Q3: How does mobile phase pH affect my HILIC separation, and how should I control it? Mobile phase pH significantly impacts the charge state of both your analytes and the stationary phase, thereby affecting retention and selectivity. The actual pH in a high-organic mobile phase is about 1-1.5 units higher than that of the aqueous buffer alone [32].

- Solution: Use volatile buffers like 10-20 mM ammonium formate or acetate for MS compatibility. Empirically test different aqueous buffer pH values (e.g., pH 3 and 6) to find the optimal conditions for your specific analytes, as predicting behavior based on aqueous pKa alone is difficult [31] [32].

Q4: My MS sensitivity fluctuates wildly even with stable retention times. Why? This can be related to buffer or additive concentration in the mobile phase. High buffer concentrations can lead to source contamination and ion suppression in the MS [32].

- Solution: Use buffer concentrations in the 10-20 mM range as a starting point. Ensure that the buffer concentration is consistent in both the aqueous and organic mobile phase components to maintain stable ionic strength during the gradient [32].

Troubleshooting Common Problems Table

| Problem | Potential Causes | Recommended Solutions |

|---|---|---|

| Irreproducible Retention Times | Insufficient column conditioning/equilibration [31] | Condition with 50 column volumes (isocratic) or 10 blank runs (gradient). Equilibrate with 10 column volumes between runs [31]. |

| Poor Peak Shape | Mismatched injection solvent [31] | Reconstitute sample in a solvent that matches the starting mobile phase organic ratio (e.g., 75-90% ACN). |

| Low or Fluctuating MS Signal | High buffer concentration; Buffer precipitation [31] [32] | Reduce volatile buffer concentration to 10-20 mM. Ensure equal buffering in both mobile phases A and B [32]. |

| No Retention of Analytic | Organic content too low; Wrong column chemistry [33] | Increase acetonitrile content to 70-90%. Verify that your analyte is polar (negative log P) and select an appropriate stationary phase [33]. |

| Multiple Peaks for a Single Compound | Counterion effects; Analyte impurities [34] | Ensure the counterion in your standard matches the ammonium buffer. Use a high-purity standard and include buffer in the sample solvent [34]. |

Experimental Protocols for Robustness Validation

Protocol 1: Long-Term System Suitability Monitoring for IgG N-Glycan Profiling

This protocol, adapted from high-throughput clinical glycomics studies, provides a framework for validating the long-term robustness of your HILIC-UPLC glycan profiling method [16].

1. Principle Regularly analyze a well-characterized control sample (e.g., pooled human IgG) to monitor the stability of key chromatographic performance indicators over time, ensuring the method remains reliable over weeks or months [16].

2. Materials

- Control Sample: Purified and desalted human IgG or a commercial monoclonal antibody.

- Glycan Release Kit: PNGase F enzyme and buffers.

- Labeling Reagent: 2-aminobenzamide (2-AB) or 2-aminobenzoic acid (2-AA) [35] [36].

- HILIC Column: e.g., UPLC BEH Glycan or similar, 1.7 µm particle size, 2.1 x 100 mm or 150 mm [16] [33].

- Mobile Phase A: 50-200 mM ammonium formate, pH 4.5-7.0 (aqueous).

- Mobile Phase B: Acetonitrile (HPLC grade).

3. Step-by-Step Procedure

- Sample Preparation: Following a standardized protocol, release N-glycans from the control IgG using PNGase F, and label them with a fluorescent tag (e.g., 2-AB) via reductive amination [16] [37].

- Purification: Remove excess labeling reagent using solid-phase extraction (SPE) with hydrophilic cartridges.

- Chromatography:

- Column: HILIC UPLC (e.g., BEH Glycan, 1.7 µm, 2.1 x 150 mm).

- Temperature: 40-60°C.

- Gradient: Use a linear gradient from high organic to high aqueous. Example: 70-85% B to 50-60% B over 15-25 minutes.

- Flow Rate: 0.2-0.4 mL/min.

- Detection: Fluorescence (Ex: 330 nm, Em: 420 nm for 2-AB) and/or ESI-MS [37].

- Data Analysis: Calculate the relative abundance (%) of major glycan peaks (e.g., G0, G1, G2, G0F, G1F, G2F) by dividing individual peak areas by the total integrated area.

4. Key Parameters for Robustness Validation Monitor the following metrics for the control sample over multiple runs (n ≥ 5) and track them on a control chart:

- Retention time of a key peak (e.g., G0F) - indicates column stability.

- Relative abundance of a major glycan peak (e.g., G0F) - indicates quantitative precision.

- Peak width at half height for a well-resolved peak - indicates chromatographic efficiency.

- Resolution between two critical isomer pairs [16].

Protocol 2: Strategic Method Optimization Using Experimental Design

For developing a new, robust method or troubleshooting a problematic one, a structured approach to optimization is crucial.

1. Column and Mobile Phase Selection Workflow The following diagram outlines the logical decision process for establishing initial HILIC conditions.

2. Critical Optimization Steps

- Stationary Phase: Select based on analyte properties. Bare silica is a common starting point. Amide columns are popular for glycan separations due to their high stability and reproducibility [16] [33].

- Mobile Phase: Start with a gradient of 80% ACN to 60% ACN. Use volatile buffers (10-20 mM ammonium formate/acetate) for MS compatibility. Adjust pH (aqueous) between 3.0 and 6.0 to optimize selectivity [31] [32] [33].

- Sample Solvent: Critical for peak shape. Always match the organic content of the initial mobile phase [31].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table: Key Reagents and Materials for HILIC-UPLC Glycan Profiling

| Item | Function / Purpose | Example / Specification |

|---|---|---|

| PNGase F Enzyme | Enzymatically releases N-linked glycans from glycoproteins for analysis [37]. | Recombinant, glycerol-free. |

| Fluorescent Label (2-AB/2-AA) | Derivatizes released glycans via reductive amination, enabling fluorescence detection and improved MS sensitivity [35] [36]. | 2-Aminobenzamide (2-AB), 2-Aminobenzoic acid (2-AA). |

| Solid-Phase Extraction (SPE) Cartridges | Purifies labeled glycans by removing salts, detergents, and excess labeling reagent after the derivatization reaction [16]. | Hydrophilic interaction (HILIC) or porous graphitized carbon (PGC) cartridges. |

| Volatile Buffers | Provides pH control and ionic strength in the mobile phase without causing ion suppression or source contamination in MS detection [31] [32]. | Ammonium formate, Ammonium acetate (≥99% purity). |

| HILIC-UPLC Column | The core separation component; retains and resolves polar glycan structures based on their hydrophilicity [16] [33]. | e.g., BEH Amide, 1.7 µm, 2.1 x 150 mm. |

| System Suitability Standard | A well-characterized glycan sample run periodically to validate system performance and ensure data integrity over time [16] [37]. | e.g., Released glycans from a commercial monoclonal antibody. |

Workflow for Detailed Glycan Characterization

For a comprehensive analysis that includes structural confirmation, the HILIC-UPLC-FLR method can be coupled to mass spectrometry, as shown in the following integrated workflow.

Troubleshooting Guides and FAQs

Frequently Asked Questions

Q1: How does high-throughput screening in 96-well plates accelerate research in glycomics? High-throughput 96-well plate platforms significantly increase the number of samples and conditions that can be screened simultaneously. When combined with automated liquid handling and advanced analytics like high-throughput metabolomics, this approach allows for the rapid preliminary screening of a large number of novel conditions or formulations, drastically reducing the time and labor associated with traditional serial testing methods [38]. This is crucial for fields like glycomics, where robust and stable methodologies are required to detect small biological variations over long periods [16].

Q2: What are the most common sources of error when using automated liquid handlers, and how can I mitigate them? Common errors often relate to the liquid properties or instrument setup. The table below summarizes frequent issues and their solutions [39]:

| Observed Error | Possible Source of Error | Recommended Solution |

|---|---|---|

| Dripping tip or drop hanging from tip | Difference in vapor pressure of sample vs. water used for adjustment | Pre-wet tips sufficiently; add an air gap after aspirate |

| Droplets or trailing liquid during delivery | Liquid characteristics (e.g., viscosity) different from water | Adjust aspirate/dispense speed; add air gaps or blow-outs |

| Diluted liquid with each successive transfer | System liquid is in contact with the sample | Adjust the leading air gap |

| Serial dilution volumes varying from expected concentration | Insufficient mixing | Measure and optimize liquid mixing efficiency |

Q3: Why is a compositional data analysis (CoDA) approach critical for high-throughput glycomics data? Glycomics data, often expressed as relative abundances, is inherently compositional. This means that an increase in the relative abundance of one glycan mathematically necessitates a decrease in others. Applying traditional statistical analysis to this type of data can generate spurious correlations and high false-positive rates. A CoDA framework, using transformations like the center log-ratio (CLR), accounts for this data structure and is essential for deriving biologically valid conclusions from comparative glycomics studies [19].

Troubleshooting Common Experimental Issues

Issue: Inconsistent results across a 96-well plate during a glycomics assay.

| Possible Cause | Diagnostic Steps | Corrective Action |

|---|---|---|

| Liquid Handler Inaccuracy | Check calibration with a dye-based assay; run a test plate to check for a repeating pattern of error. | Perform regular maintenance; ensure the pipetting method (wet vs. dry) is appropriate for the reagent [39]. |

| Insufficient Mixing | Visually inspect wells for stratification; test mixing efficiency with dyes. | Optimize the mixing steps in your automated protocol; ensure mixing speed and duration are sufficient [39]. |

| Edge Evaporation Effects | Compare results in edge wells versus interior wells. | Use plates with secure seals; ensure the environmental chamber of the liquid handler is humidified. |

| Faulty Plate Seal | Visually inspect the seal for wrinkles or lifting. | Reseal the plate, ensuring a uniform and tight seal across all wells. |

Issue: High background or poor separation in a 96-well microplate chromatography step.

| Possible Cause | Diagnostic Steps | Corrective Action |

|---|---|---|

| Channeling in the Well | Check for consistent flow-through across all wells. | Ensure the adsorbent bed is packed evenly and that upper and lower frits are properly seated to maintain a uniform flow path and residence time [40]. |

| Overloaded Adsorbent | Reduce the amount of sample loaded per well. | Reduce the sample load and re-run the assay to see if separation improves. |

| Inconsistent Elution Conditions | Review the pH and salinity gradients applied across the plate. | Use the microplate format to systematically screen a wide range of elution conditions (e.g., pH and salinity) to identify the optimal buffer for separation [40]. |

Experimental Protocols for Validation

Protocol 1: Validating 96-Well Plate Storage for RBCs and Glycobiology Studies

This protocol outlines a method for validating the use of deep 96-well plates as a storage platform, which can be adapted for long-term robustness studies in glycomics [38].

1. Materials and Reagents

- Storage Plates: 2-ml deep polypropylene 96-well plates.

- Seals: Metallic seals (e.g., SILVERseal).

- Positive Control: Standard PVC storage bags.

- Specialized Equipment: Anaerobic glovebox (for hypoxic condition studies), oxygen barrier bags, O2 sorbent, bar heat sealer, multichannel pipette, microplate reader.

2. Sample Preparation and Plate Setup

- Prepare sample pools from compatible source units.

- For normoxic conditions, process samples in a laminar flow hood.

- For hypoxic conditions, process samples in an N2-filled glovebox maintained at <1% pO2.

- Dispense 2 ml of sample suspension into each well of the 96-well plate.

- Seal plates securely. For H-condition plates, place them inside oxygen barrier bags with an O2 sorbent and heat-seal.

3. Storage and Sampling

- Store all plates and control bags at 4°C.

- Sample the plates bi-weekly (e.g., on day 0, 14, 28, and 42).

- Use a multichannel pipette to transfer aliquots from the storage plate to assay plates for analysis.

4. Key Metrics for Long-Term Robustness Validation The following quantitative metrics should be tracked over time to validate system robustness [38]:

| Metric | Assay Method | Frequency | Benchmark for Success |

|---|---|---|---|

| Hemolysis | Supernatant hemoglobin measured via Harboe spectrophotometric method adapted for 96-well plates. | Bi-weekly | <1% (FDA benchmark); <0.8% (EU benchmark) |

| ATP Levels | Hexokinase kit assay adapted for 96-well workflow. | Bi-weekly | Comparable to values from standard bag-stored controls |

Protocol 2: A Compositional Data Analysis (CoDA) Workflow for Robust Glycomics

This protocol ensures the statistical rigor of data generated from high-throughput glycomics platforms [19].

1. Data Transformation

- Center Log-Ratio (CLR) Transformation: Normalize glycan abundances to the geometric mean of the sample. This is the preferred initial step to transform the data from the Aitchison simplex to real space.

2. Incorporate a Scale Uncertainty Model

- Acknowledge and model potential differences in the total number of glycan molecules between sample conditions to prevent distortions in relative abundance interpretations.

3. Data Analysis and Interpretation

- Differential Expression: Apply statistical tests to the transformed data to identify glycan abundance differences between conditions.

- Similarity Analysis: Use CoDA-appropriate distance metrics, such as the Aitchison distance (Euclidean distance after CLR transformation), for clustering samples. This provides a more valid measure of similarity than non-compositional metrics.

- Cross-Class Correlations: Analyze interdependencies between different glycan classes using correlation methods designed for compositional data (e.g., similar to SparCC).

Workflow Visualization

Diagram: High-Throughput Glycomics Workflow

Diagram: Compositional Data Analysis Pipeline

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in High-Throughput Workflows |

|---|---|

| Deep 96-Well Polypropylene Plates | The core platform for high-throughput sample storage and processing, allowing parallel experimentation under controlled conditions [38]. |

| Metallic Seals (e.g., SILVERseal) | Provide a secure, airtight seal for plates, preventing evaporation and contamination during long-term storage or incubation [38]. |

| Oxygen Barrier Bags & Sorbents | Essential for creating and maintaining hypoxic storage conditions within plate-based systems, enabling the study of oxygen-sensitive biological processes [38]. |

| Chromatography Microplates | Specialized 96-well plates with frits and outlets that function as mini-columns, enabling high-throughput screening of adsorbents and purification conditions [40]. |

| CLR/ALR Transformation Algorithms | Computational tools essential for the statistically rigorous analysis of compositional glycomics data, controlling false-positive rates and enabling valid biological conclusions [19]. |

| Automated Liquid Handler | Robotic systems with motorized pipettes or syringes that dispense specified volumes, reducing human error, labor, and contamination while ensuring consistency [41]. |

This technical support center provides targeted troubleshooting and methodological guidance for scientists employing two pivotal mass spectrometry technologies in glycomics research: Data-Independent Acquisition (DIA) and Matrix-Assisted Laser Desorption/Ionization Time-of-Flight (MALDI-TOF-MS). Glycomics, the study of complex sugar structures in biological systems, presents unique challenges for robust, long-term analysis. The content herein is framed within a broader thesis on validation and robustness, providing researchers and drug development professionals with clear protocols and solutions to ensure data consistency and reliability in their experiments.

Technical Support and Troubleshooting Guides

Data-Independent Acquisition (DIA) Mass Spectrometry

Frequently Asked Questions (FAQs)

What is the primary advantage of DIA over Data-Dependent Acquisition (DDA) in long-term glycomics studies? DIA's key advantage is its superior quantitative accuracy, precision, and reproducibility. Unlike DDA, which stochastically selects intense precursor ions, DIA systematically fragments and analyzes all ions within pre-defined mass-to-charge (m/z) windows. This unbiased acquisition greatly mitigates the issue of missing values across multiple experimental runs, a critical factor for long-term robustness validation [42] [43].

Why are DIA data analysis and software tools so critical? DIA generates highly multiplexed fragment ion spectra where the direct link between a precursor and its fragments is lost. This requires sophisticated software tools to deconvolute the data, typically using a peptide spectral library. The choice of software can significantly impact the sensitivity and reliability of identification and quantification. It is recommended to employ multiple, orthogonal DIA analysis tools to enhance the robustness of findings [43] [44].

How can I improve the sensitivity and selectivity of my DIA method? Method performance is influenced by several factors. Using narrower precursor isolation windows can reduce the number of co-fragmented ions, enhancing selectivity. Furthermore, employing mass analyzers with high resolution and fast scan speeds, such as modern Q-TOF or Q-Orbitrap systems, improves peptide identification and quantification. The use of ion mobility spectrometry (e.g., FAIMS) can also add a separation dimension to reduce sample complexity [42] [43].

Troubleshooting Guide for DIA Experiments

| Problem Scenario | Expert Recommendations |

|---|---|

| Low peptide identification rates | - Generate a project-specific spectral library using DDA analysis of your samples [42]. - Verify that the correct search parameters (e.g., species, enzyme, mass tolerance) are used in your database search [45]. - Consider using a variable isolation window scheme to optimize selectivity [42]. |

| Poor chromatographic performance | - Calibrate your LC system using a peptide retention time calibration mixture [45]. - Verify settings for liquid chromatography (LC) acquisition methods, including gradient length and pressure [45]. |

| Inconsistent quantification | - Use a HeLa protein digest standard to test your sample clean-up method and check for peptide loss [45]. - For labeled experiments, fractionate samples to reduce complexity [45]. - Ensure consistent sample preparation protocols across all runs to minimize technical variability. |

MALDI-TOF-MS for Synthetic Polymers and Glycans

Frequently Asked Questions (FAQs)

Why is matrix selection so critical for successful MALDI-TOF-MS analysis? The matrix serves as a dispersant, desorbent, and is responsible for the "soft ionization" of the analyte via proton transfer. Selecting a matrix whose relative polarity or hydrophobicity closely matches that of your analyte is paramount for maximizing ionization efficiency and generating high-quality spectra [46].

My polymer sample has a high polydispersity ( > 1.2). Why are my mass results inaccurate? MALDI-TOF-MS is inherently biased against high molecular weight oligomers in polydisperse samples, often due to detector saturation. The resulting spectra show attenuated or missing high-mass signals. Caution should be exercised when directly measuring the molecular weight of highly polydispersed polymers with this technique [46].

Should I use the linear or reflectron mode for analysis? This choice is based on the analyte's molecular weight. Use reflectron mode for lower molecular weight polymers (e.g., < 40 kDa) to achieve higher mass resolution and signal-to-noise. Use linear mode for higher MW analytes to avoid fragmentation in the reflectron and subsequent poorly resolved spectra [46].

Troubleshooting Guide for MALDI-TOF-MS Experiments

| Problem Scenario | Expert Recommendations |

|---|---|

| Poor ionization/weak signal | - Ensure the matrix's polarity matches the analyte (e.g., DCTB is a "universal matrix" for medium-low polarity polymers) [46]. - Add an ionization agent ("salt") for polymers with limited pi bonds or heteroatoms [46]. - Re-prepare the sample using a common solvent for all sample components to achieve homogeneous co-crystallization [46]. |

| Unresolved spectra or low resolution | - For low MW analytes, switch to the reflectron mode to improve resolution [46]. - For high MW analytes, confirm the instrument is in linear mode to prevent fragmentation. - Re-evaluate the matrix-to-analyte ratio and sample spot homogeneity. |

| Inconsistent shot-to-shot reproducibility | - Avoid using multiple solvents with dissimilar evaporation rates, which cause segregation during crystallization [46]. - Consider alternative sample preparation methods such as solvent-free, multi-layer deposition, or electrospray for more uniform sample films [46]. |

Experimental Protocols for Robust Glycomics Research

Protocol 1: DIA Method Development for Glycoproteomics

This protocol outlines a robust workflow for implementing DIA in a glycomics context, focusing on parameters that ensure long-term reproducibility.

- Sample Preparation: Utilize a standardized, multi-enzyme digestion protocol (e.g., trypsin, PNGase F) to comprehensively release glycans and generate glycopeptides. Include a quality control step using a HeLa protein digest standard to validate the entire sample preparation workflow [45].

- Spectral Library Generation: Create a project-specific spectral library by performing DDA analysis on a representative pool of all sample types in your study. This library directly links precursor ions to their fragments and is crucial for interpreting DIA data [42].

- DIA Acquisition Parameters:

- Isolation Windows: Implement a variable window scheme based on the density of precursor ions in the m/z range of interest. This balances selectivity and cycle time [42].

- Cycle Time: Aim for a cycle time that allows for 8-10 data points across a typical chromatographic peak to ensure accurate quantification.

- Ion Mobility: If available, use ion mobility (e.g., FAIMS, TIMS) to add a gas-phase separation dimension, reducing spectral complexity and improving ion selectivity [43].

- Data Processing and Robustness Validation:

- Process the raw DIA data using at least two different software tools (e.g., OpenSWATH, DIA-NN, Skyline) for orthogonal validation of results [43].

- Incorporate internal standard peptides for absolute quantification and to monitor instrument performance drift over time.

- For glycomics-specific analysis, use tools like GlyCompareCT to decompose glycan structures into substructures (glycomotifs). This addresses data sparsity and quantifies hidden biosynthetic relationships, increasing statistical power for long-term studies [47].

Protocol 2: MALDI-TOF-MS Optimization for Glycan and Polymer Analysis

A systematic strategy is key to obtaining high-quality, reproducible MALDI-TOF mass spectral data for glycans and synthetic polymers.

- Analyte Assessment: Characterize the polymer or glycan's charge, molecular structure, solubility, and polydispersity. This determines instrument polarity, the need for a matrix or additives, and the appropriate analysis mode [46].

- Matrix Selection: Choose a matrix based on analyte polarity. Refer to established polarity scales (e.g., Table 1: Common Matrices). For general use, DCTB is recommended. For negative mode, use basic matrices like 9-aminoacridine (9AA) [46].

- Sample Preparation - The Dried-Droplet Method:

- Prepare stock solutions of the matrix and analyte in the same solvent (e.g., THF, methanol) to ensure homogeneous co-crystallization.

- Mix the matrix, analyte, and ionization agent (e.g., NaTFA, LiTFA) at an optimal molar ratio (e.g., 1000:1:1 matrix-to-analyte-to-salt).

- Spot 1-2 µL of the mixture onto the MALDI target and allow it to dry under ambient conditions to form a thin, crystalline layer.

- Instrument Parameter Optimization:

- Set the instrument to the correct mode: reflectron for MW < 40 kDa, linear for MW > 40 kDa.

- Start with low laser power and incrementally increase it until a strong, stable signal is obtained with minimal background noise.

- Accumulate a sufficient number of shots (e.g., 1000-2000) from different spot locations to ensure a representative spectrum.

The Scientist's Toolkit: Key Research Reagent Solutions

The following table details essential materials and reagents referenced in the experimental protocols to support robust and reproducible research.

| Item | Function/Benefit | Example(s) |

|---|---|---|