Automating Hazardous Chemical Handling in Glycan Sample Prep: A Guide to Safer, More Reproducible Research

This article addresses the critical need to automate the handling of hazardous chemicals—such as hydrazine, strong acids, and fluorophores—in glycan sample preparation workflows.

Automating Hazardous Chemical Handling in Glycan Sample Prep: A Guide to Safer, More Reproducible Research

Abstract

This article addresses the critical need to automate the handling of hazardous chemicals—such as hydrazine, strong acids, and fluorophores—in glycan sample preparation workflows. Targeting researchers, scientists, and drug development professionals, we explore the foundational risks of manual processes, detail current automated methodologies and platforms, provide troubleshooting and optimization strategies for implementation, and validate performance through comparative data on safety, reproducibility, and throughput. The synthesis aims to empower labs to adopt automation, enhancing both personnel safety and data quality in glycoscience and biopharmaceutical development.

The Critical Need: Why Automating Hazardous Steps in Glycan Analysis is Non-Negotiable

Technical Support Center: Troubleshooting & FAQs

FAQ 1: During hydrazinolysis, my glycan yield is low and I observe significant degradation. What could be the cause and how can I mitigate this?

- Answer: Low yield with degradation often points to suboptimal reaction conditions or contamination. Hydrazine is hygroscopic; water contamination hydrolyzes the reagent, reducing its efficacy and increasing side reactions. Ensure anhydrous conditions by using fresh, sealed bottles and conducting the reaction under an inert atmosphere (argon/nitrogen). Strict temperature and time control is critical. For N-linked glycans, 60°C for 6-10 hours is standard; O-linked glycans require 60°C for 4-6 hours. Over-exposure leads to peeling degradation. Implement a desiccant in the reaction vessel. Automated liquid handling systems with sealed, climate-controlled modules can precisely manage these parameters, removing human error and exposure.

FAQ 2: After labeling with aromatic amine fluorophores (like 2-AB), my HPLC/UPLC profiles show multiple peaks for a single glycan. What does this indicate and how can I resolve it?

- Answer: Multiple peaks indicate incomplete or over-labeling, often due to impure fluorophore, suboptimal labeling conditions, or insufficient cleanup. The reductive amination reaction (glycan + fluorophore + sodium cyanoborohydride) is sensitive to the dye:glycan ratio, temperature, and pH.

- Solution: Follow this optimized protocol:

- Labeling Mix: Combine dried glycans with a freshly prepared solution of 2-AB (or similar) in DMSO:acetic acid (70:30 v/v) and 1M sodium cyanoborohydride in tetrahydrofuran. Use a molar excess of dye (~50-100 fold).

- Reaction: Incubate at 65°C for 2 hours in a dry heating block.

- Cleanup: Use normal-phase solid-phase extraction (SPE) cartridges (e.g., PhyNexus GlycanClean S). Condition with water and acetonitrile. Load the reaction mixture, wash with 95-98% acetonitrile to remove excess dye, and elute glycans with water. Automation using SPE workstations ensures reproducibility and minimizes contact with toxic fluorophores.

- Solution: Follow this optimized protocol:

FAQ 3: The acid hydrolysis step for sialic acid analysis is giving inconsistent results. What are the critical parameters?

- Answer: Inconsistency stems from the extreme sensitivity of sialic acids to acid strength, temperature, and time. Mild acid conditions are required to release sialic acids without destroying them or desialylating the underlying glycan.

- Standardized Protocol: Use 2M acetic acid (not stronger mineral acids) at 80°C for precisely 2 hours. Alternatively, enzyme-based release (e.g., neuraminidase) is milder and more specific. For automated handling, a thermal cycler with precise temperature control and heated lids is ideal. Always include a sialic acid standard (e.g., Neu5Ac) processed in parallel to validate the reaction.

FAQ 4: How can I safely handle and dispose of hydrazine and toxic fluorophores like 2-AA?

- Answer: Engineering controls are paramount.

- Handling: Always work in a certified fume hood. Use double gloves (nitrile). Employ closed-system liquid handling robots or syringe pumps for transferring hydrazine. For solids like 2-AA, use a dedicated weighing station with HEPA filtration.

- Disposal: Never pour down the sink. Collect all waste (liquid and solid) in compatible, labeled hazardous waste containers specifically for "hydrazine waste" or "toxic dye waste." Neutralize small volumes of hydrazine with a dilute sodium hypochlorite (bleach) solution in a fume hood before disposal, following your institution's Environmental Health & Safety (EHS) protocols. Automated platforms integrate waste lines into sealed, secondary containment vessels.

Data Summary Table: Key Hazardous Reagents in Glycan Analysis

| Reagent | Primary Use | Key Hazard | Recommended Automated Handling Solution |

|---|---|---|---|

| Anhydrous Hydrazine | Chemical release of glycans from proteins (hydrazinolysis). | Highly toxic, corrosive, flammable, suspected carcinogen. | Robotic liquid handler in an enclosed glovebox or vented enclosure. |

| Trifluoroacetic Acid (TFA) | Acid hydrolysis for sialic acid release or HPLC mobile phase. | Severe skin/eye burns, corrosive fumes. | Integrated acid vapor containment system on the solvent delivery module. |

| 2-Aminobenzamide (2-AB) | Fluorescent labeling via reductive amination. | Irritant, toxic if ingested/inhaled. | Solid-dispensing robot or pre-made, sealed labeling kits. |

| Sodium Cyanoborohydride | Reducing agent in reductive amination labeling. | Toxic, releases hydrogen cyanide upon contact with acid. | Prepared as a stable stock solution in THF; handled by liquid handler. |

| Dimethyl Sulfoxide (DMSO) | Solvent for fluorophores in labeling reactions. | Penetrates skin, can carry other toxins into the body. | Standard liquid handling with appropriate tip disposal. |

Research Reagent Solutions Toolkit

| Item | Function | Hazard Mitigation Context |

|---|---|---|

| Anhydrous Hydrazine (≥98%) | Potent nucleophile for cleaving glycosidic bonds in glycoprotein analysis. | Primary target for automation; use sealed ampoules or bottles with septa for robotic aspiration. |

| 2-Aminobenzoic Acid (2-AA) / 2-AB | Common fluorophores for labeling released glycans for detection (HPLC, CE). | Pre-weighed aliquots or sealed, stabilized labeling mixtures reduce exposure. |

| Sodium Cyanoborohydride (NaBH3CN) | Selective reducing agent for stable Schiff base formation during labeling. | Handle in alkaline conditions; automated preparation of fresh stock solutions minimizes decomposition. |

| Acetic Acid & TFA (various strengths) | Used in controlled hydrolysis and as volatile HPLC buffers. | Automated titrators or closed-bottle solvent systems prevent vapor inhalation. |

| Normal-Phase SPE Cartridges | Cleanup of labeling reactions to remove excess dye and salts. | Automation-friendly 96-well plate format enables high-throughput, hands-off processing. |

| Inert Atmosphere Glovebox | Provides water- and oxygen-free environment for hydrazinolysis. | Can be integrated with an internal robotic arm for complete process automation. |

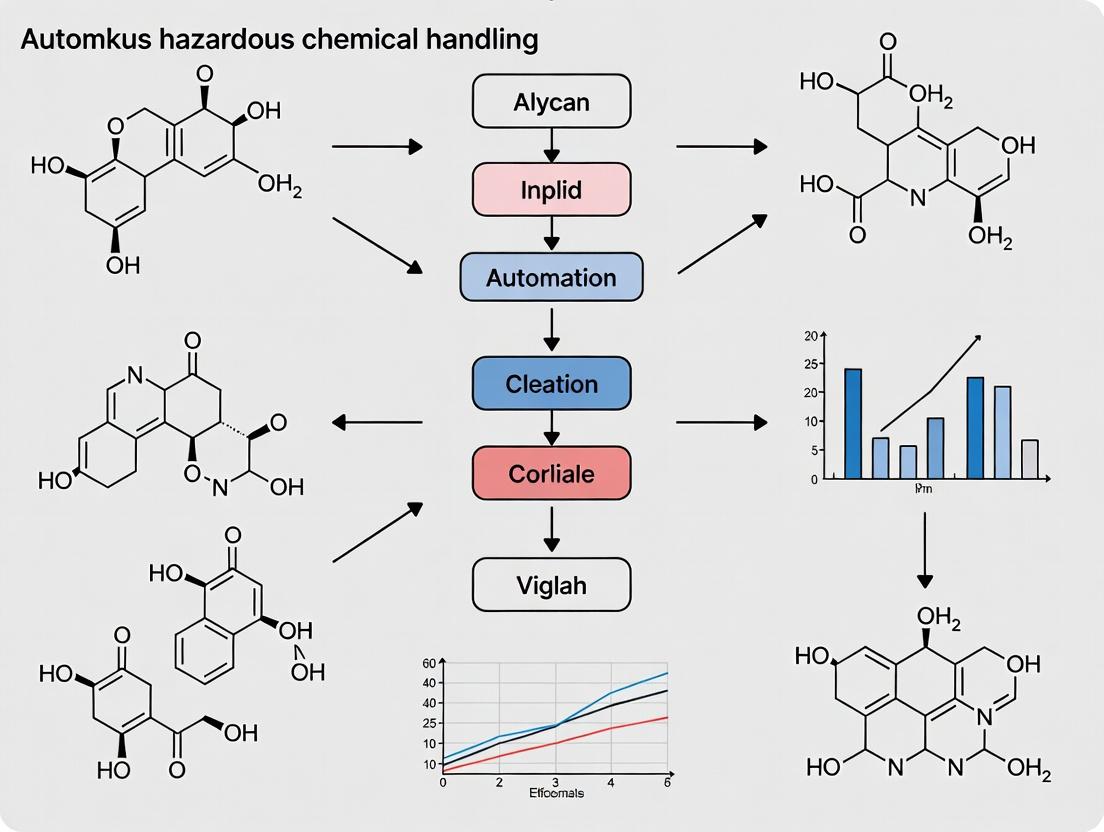

Diagram: Automated Hazardous Glycan Sample Prep Workflow

Diagram: Reductive Amination Labeling Reaction Pathway

Technical Support Center: Troubleshooting & FAQs

Frequently Asked Questions (FAQs)

Q1: During manual chemical derivatization of glycans, my replicate samples show high variability in labeling efficiency (>15% CV). What could be the cause and how can I fix it? A: High variability is a common bottleneck in manual protocols, primarily due to inconsistent pipetting timing and reagent mixing. Quantitative data from recent studies indicates that manual handling can introduce a 12-25% coefficient of variation (CV) in fluorophore incorporation. To resolve this, standardize the vortexing time and speed. Use a timer for precise incubation steps. Consider implementing a semi-automated liquid handler for the derivatization reagent addition step, which studies show can reduce CV to below 5%.

Q2: I suspect inconsistent sample drying in a vacuum centrifuge is causing low yield in my glycan cleanup step. How can I troubleshoot this? A: Incomplete or over-drying are significant risks. First, verify the centrifuge's pressure gauge reads <0.1 mBar. Calibrate the timer. For a 50µL aqueous sample, optimal drying time is typically 2-2.5 hours at 40°C. Create a validation protocol: prepare three control samples with a known amount of a standard glycan, dry for 1.5, 2.0, and 2.5 hours, then quantify recovery. The data should identify the optimal window. Over-drying (>3 hours) can lead to irreversible adsorption and yield losses exceeding 30%.

Q3: My manual solid-phase extraction (SPE) for glycan purification results in clogged cartridges and low recovery. What steps should I take? A: Clogging indicates particulate matter or improper cartridge conditioning. Always centrifuge your glycan sample at 14,000 x g for 10 minutes before loading. Ensure you follow the conditioning (80% ACN, 0.1% TFA), equilibration (0.1% TFA) wash (0.1% TFA), and elution (20% ACN, 0.1% TFA) steps with precise volumes. A common error is allowing the cartridge bed to dry between steps; it must remain wet. Implement a visual checklist for each step. Recovery for manual SPE under optimal conditions is 70-85%, but drops to 40-60% with improper handling.

Q4: I am experiencing dermatitis and eye irritation despite using fume hoods and gloves. What safety protocols might be failing? A: This highlights critical health hazards. Re-evaluate your PPE: are you using nitrile gloves (check for pinhole leaks)? Are safety goggles with side shields used, not just glasses? Verify fume hood face velocity (>100 fpm) and that work is performed 6 inches inside the sash. The primary risks are exposure to volatile reagents like trifluoroacetic acid (TFA) and pyridine. Refer to the quantitative hazard data in Table 1. Implement mandatory glove change every 60 minutes and install a splash guard. Report all symptoms to your institution's health and safety office immediately.

Troubleshooting Guides

Issue: Inconsistent Fluorescence Intensity in 2-AB Labeled Glycan Analysis by UPLC. Symptoms: High CV between technical replicates, poor calibration curve linearity. Diagnosis Protocol:

- Check Reagent Freshness: Prepare fresh 2-AB labeling solution (2-AB in DMSO:Acetic Acid 70:30 v/v) daily. Old reagent increases variability.

- Standardize Incubation: Ensure all samples are incubated at 65°C for exactly 2 hours in a calibrated, non-cycling heating block (water bath preferred for even heat transfer).

- Verify Quenching: The reaction must be stopped with 100% acetonitrile in a 1:1 ratio, added precisely at the 2-hour mark.

- Post-Labeling Cleanup: Use a consistent, validated HILIC-SPE or paper chromatography method. Manually timing the elution step is a major bottleneck; use a metronome or timer. Solution: Introduce an internal fluorescent standard added prior to cleanup to distinguish between labeling variability and instrument detection variability. If the CV of the internal standard is low (<5%), the issue is in the labeling protocol.

Issue: Low Throughput and Researcher Fatigue in Multi-Step Cleanup. Symptoms: Throughput limited to 8-12 samples per day, increased error rates in afternoon sessions. Diagnosis: Manual protocols are serial processes with physical bottlenecks. Timed steps (e.g., "apply sample, wait 5 min, wash, wait 5 min, elute") prevent parallel processing. Solution: Re-engineer the workflow into parallel batches. Use a multi-channel pipette for wash and elution steps across multiple SPE cartridges arranged in a rack. Implement a visualized workflow timer (see Diagram 1). The primary bottleneck is often the sample loading step; evaluate automation for this specific step to break the bottleneck.

Data Presentation

Table 1: Quantitative Risks in Manual Glycan Sample Preparation

| Risk Factor | Quantitative Measure (Manual Protocol) | Impact (Compared to Automated Baseline) | Primary Health Hazard |

|---|---|---|---|

| Pipetting Variability | CV of 8-15% for volumes <10 µL | Increases overall process CV by 35% | Repetitive strain injury |

| Incubation Timing | ± 2-5 minute deviation from target | Can alter derivatization yield by 10-20% | Thermal burn (from heating blocks) |

| Chemical Exposure | Fume hood containment efficiency ~95% | 5% exposure risk per handling event | Dermatitis, respiratory irritation (TFA, Acetic Acid) |

| Sample Cross-Contamination | Estimated 0.1-1% carryover per manual transfer | Significant for low-abundance glycan profiling | N/A |

| Process Throughput | 4-8 samples per researcher per hour | 60-70% lower than microplate-based automation | Prolonged exposure, fatigue |

Table 2: Bottleneck Analysis in a Standard Manual N-Glycan Release & Labeling Workflow

| Protocol Step | Avg. Hands-On Time (Min/Sample) | Avg. Wait Time (Min) | Bottleneck Severity | Automation Potential |

|---|---|---|---|---|

| Protein Denaturation & PNGase F Digestion | 3 | 120 (O/N) | Low (Waiting) | High (Liquid Handling) |

| Solid-Phase Extraction (SPE) Cleanup | 12 | 15 | Critical (Serial) | Very High |

| Chemical Derivatization (2-AB Labeling) | 8 | 120 | High (Timing-Sensitive) | High |

| Post-Labeling Cleanup | 10 | 10 | High (Serial) | Very High |

| Sample Dilution & Vialing | 4 | 0 | Medium | Very High |

Experimental Protocols

Protocol 1: Quantitative Assessment of Manual Pipetting Variability Objective: To measure the coefficient of variation (CV) introduced by manual pipetting of viscous glycan derivatization reagents. Materials: 2-AB labeling solution (see Toolkit), 10 µL calibrated pipette, amber microcentrifuge tubes, fluorescence plate reader. Methodology:

- Prepare a 1 µg/µL stock of a standard glycoprotein (e.g., IgG) digest.

- Aliquot 10 µL of the stock into 20 separate tubes.

- Using the same pipette and operator, add 10 µL of 2-AB labeling solution to each tube, timing the aspiration and dispense steps naturally.

- Incubate, clean up, and analyze all samples by UPLC with fluorescence detection.

- Measure the peak area of a major glycan (e.g., FA2G2) for all 20 replicates.

- Calculate the mean, standard deviation, and CV of the peak areas. This CV quantifies the manual pipetting variability component.

Protocol 2: Health Hazard Monitoring - Surface Contamination Test Objective: To detect low-level residual contamination of hazardous chemicals (e.g., TFA) on work surfaces after manual protocols. Materials: pH indicator strips (range 1-6), deionized water, sterile swabs. Methodology:

- One hour after completing a manual SPE cleanup protocol, moisten a swab with deionized water.

- Swab a standardized area (e.g., 10x10 cm) of the bench surface near the centrifuge, pipettes, and waste container.

- Express the liquid from the swab onto a pH indicator strip.

- Record the pH. A pH below 5 indicates acidic contamination, signaling a breakdown in containment (wipe-down procedures or splashing).

- Perform this test weekly at three random locations to monitor safety protocol efficacy.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Glycan Sample Prep | Key Hazard/Risk |

|---|---|---|

| Trifluoroacetic Acid (TFA) | Ion-pairing reagent for reverse-phase SPE; acidifier in mobile phases. | Highly corrosive, causes severe burns and respiratory irritation. |

| 2-Aminobenzamide (2-AB) | Fluorescent tag for derivatizing released glycans for detection. | Irritant to eyes, skin, and respiratory system. |

| PNGase F | Enzyme for releasing N-linked glycans from glycoproteins. | Minimal hazard. Storage at -20°C required. |

| Acetonitrile (ACN) | Organic solvent for precipitation, SPE, and UPLC mobile phases. | Flammable, toxic by inhalation and skin contact. |

| Dimethyl Sulfoxide (DMSO) | Solvent for preparing 2-AB labeling solution. | Penetrates skin easily, can carry other chemicals into the body. |

| Hydrophilic Interaction (HILIC) SPE Cartridge | Microcrystalline cellulose phase for purifying labeled glycans from excess dye. | Minimal hazard. Risk of clogging and variability. |

Workflow & Pathway Diagrams

Title: Manual Glycan Prep Workflow with Risk Points

Title: Root Cause Analysis of Variability in Manual Protocols

Technical Support Center: Troubleshooting Automated Glycan Sample Preparation

Frequently Asked Questions (FAQs)

Q1: My liquid handler is consistently delivering inaccurate volumes during the derivatization step with hazardous 2-aminobenzoic acid (2-AA). What could be the cause? A: Inaccurate dispensing, especially with viscous or hazardous reagents like 2-AA, is often due to worn or incompatible tips, a mis-calibrated syringe pump, or liquid property settings. First, perform a gravimetric calibration check using water. If that passes, verify the method's liquid class parameters (aspirate/dispense speed, delay times) are optimized for the reagent's viscosity and volatility. Always use chemically resistant tips.

Q2: The integrated workstation's robotic arm is failing to transfer sample plates from the heater/shaker module to the SPE module. How do I diagnose this? A: This is a common integration error. Follow this protocol: 1) Check for physical obstructions or spilled reagents. 2) Verify the plate gripper's alignment and sensor function in the maintenance menu. 3) Confirm the deck layout coordinates in the scheduling software have not been corrupted. A plate left slightly askew on a previous module is the most frequent culprit.

Q3: I am observing high variability in my released glycan yields after automated hydrolysis. What are the key parameters to control? A: Automated hydrolysis (e.g., with hazardous anhydrous hydrazine) requires precise temperature and time control. Ensure the heated module is uniformly calibrated across all positions. Variability often stems from inconsistent sealing of microplates during the heating step, leading to evaporation. Use validated, automation-compatible sealers and include an internal standard (e.g., [¹³C₆]-labeled glycan) in your protocol to monitor recovery.

Q4: How can I prevent carryover contamination when my method sequentially handles toxic labeling reagents and clean-up buffers? A: Implement a robust wash protocol. For integrated systems: 1) Program an interim "wash station" visit for the liquid handler pipet tips between reagent additions. 2) Use a tip-to-waste liquid class for aggressive reagents. 3) Schedule a deck wash step if available. For simple handlers, design your plate map with wash reservoirs and use a "prime and pre-wash" command in the method.

Q5: The scheduling software for my integrated workstation is reporting "resource conflicts" and pausing runs. How do I resolve this? A: Resource conflicts occur when two scheduled tasks require the same device (e.g., the robotic arm, a single pipetting channel) simultaneously. Review your method's timeline view. Simplify by: 1) Increasing delay times between parallel processes. 2) Assigning tasks to specific, dedicated hardware channels if available. 3) Ensuring all device communication links are active to prevent false "busy" signals.

Troubleshooting Guide: Critical Error Codes

| Error Code | Module Affected | Probable Cause | Immediate Action | Long-term Solution |

|---|---|---|---|---|

| LH-407 | Liquid Handler (Pipetting) | Pressure monitoring failure during aspiration of viscous reagent. | Abort run, check for clogged tip/line. Re-prime system. | Re-optimize liquid class (reduce aspirate speed, add air gap). Use larger bore tips. |

| ARM-112 | Robotic Transfer Arm | Plate detection sensor timeout. | Manually reposition plate in last known module. Reset arm. | Clean sensor lens. Re-teach deck landmark positions. |

| TEM-09 | Heater/Shaker | Temperature deviation >5°C from setpoint. | Run paused. Check for loose plate seal causing airflow. | Perform full module calibration. Verify contact between block and plate. |

| SW-Conflict | Scheduling Software | Two processes request same pipetting head. | Manually approve the software's suggested delay. | Re-write method to stagger parallel plate processing. |

Detailed Experimental Protocol: Automated 2-AA Labeling of N-Glycans

Objective: To automate the hazardous process of releasing and fluorescently labeling N-glycans from glycoproteins for subsequent analysis, minimizing researcher exposure.

Materials:

- Automated Integrated Workstation (Liquid handler, heater/shaker, SPE module, robotic arm)

- Glycoprotein sample in 96-well plate

- Peptide-N-Glycosidase F (PNGase F)

- Anhydrous Hydrazine (Hazardous)

- 2-Aminobenzoic Acid (2-AA), Sodium Cyanoborohydride (Hazardous)

- Dimethyl sulfoxide (DMSO)

- SPE Plates (e.g., HILIC or Graphitized Carbon)

- Automation-compatible sealing films

Methodology:

- Enzymatic Release: The liquid handler adds PNGase F in buffer to glycoprotein samples. The plate is sealed, transferred via arm to the heater/shaker, and incubated at 37°C for 18 hours.

- Chemical Labeling (Fully Automated Hazardous Step): a. The system prepares a labeling master mix of 2-AA and sodium cyanoborohydride in DMSO:acetic acid. b. With the lid closed and extraction active, it dispenses the mix to the dried glycan samples. c. The plate is sealed, transferred, and heated at 65°C for 2 hours.

- Clean-up: The robotic arm transfers the plate to the SPE module. The liquid handler executes a pre-programmed HILIC-SPE protocol (condition, load, wash, elute) to remove excess, hazardous labeling reagents.

- Analysis Ready: The eluted, purified 2-AA-labeled glycans are collected in a new plate, sealed, and ready for LC-MS or CE analysis.

Automated Hazardous Glycan Processing Workflow

The Scientist's Toolkit: Key Reagent Solutions for Automated Glycan Processing

| Reagent / Material | Function in Automation | Hazard & Handling Note |

|---|---|---|

| Peptide-N-Glycosidase F (PNGase F) | Enzyme for automated, high-throughput release of N-glycans from glycoproteins. | Low hazard. Stable in buffer for deck storage. |

| Anhydrous Hydrazine | Chemical reagent for O-glycan release. Used in specialized workflows. | Highly toxic, corrosive. Requires sealed, dedicated reagent reservoirs and thorough post-run wash protocols. |

| 2-Aminobenzoic Acid (2-AA) / Sodium Cyanoborohydride | Fluorescent label and reducing agent for glycan derivatization. | Toxic. Must be prepared in DMSO:Acetic Acid. Automation minimizes aerosol exposure during mixing and dispensing. |

| HILIC-SPE Microplate | Solid-phase extraction plate for automated clean-up of labeling reactions. | Essential for removing excess hazardous labeling reagents post-reaction. |

| Automation-compatible\nSealing Film | Prevents evaporation and cross-contamination during heated incubation steps on the deck. | Critical for assay reproducibility. Must withstand deck temperatures and not interfere with grippers. |

| Internal Standard\n(e.g., [¹³C₆]-Glycan) | Added at start of process to monitor and normalize recovery through each automated step. | Quantifies losses during hydrolysis, labeling, and clean-up for robust data. |

Technical Support Center

FAQs & Troubleshooting

Q1: During automated acid hydrolysis, my glycan yields are inconsistent. What could be the cause?

- A: Inconsistent yields are often due to variable temperature distribution or hydrolysis time discrepancies. First, verify that the heating block of the automated liquid handler is calibrated. Use an external thermocouple to map temperatures across all well positions. Ensure the hydrolysis module's sealing mechanism is functioning correctly to prevent evaporation, which concentrates acid and increases reaction severity. Adhere to the protocol below (Protocol A).

Q2: I see an error: "Liquid Level Detection Failed for Reagent X." How do I resolve this?

- A: This is typically a sensor or reagent property issue. 1) Clean the capacitive liquid level sensor probe with ethanol and deionized water. 2) Verify that the reagent's dielectric constant is within the system's specified range. For highly organic or viscous solutions (e.g., >70% DMSO), manual pre-wetting of the tip or switching to conductive liquid level detection mode may be required. 3) Check for foam or bubbles on the liquid surface, which interfere with detection.

Q3: My replicate samples show high CVs (>15%) in downstream HILIC-UPLC analysis after automated preparation. What should I check?

- A: High Coefficient of Variation (CV) points to pipetting inconsistency. Perform a gravimetric check on the automated system's volume dispensing for critical steps (e.g., derivatization reagent addition, solvent quenching). Use a dye-based absorbance assay to verify mixing efficiency after each vortexing step. Ensure that the lab environment temperature is stable, as viscosity-sensitive reagents are affected. See Protocol B for a standardized quality control procedure.

Q4: The system alarm triggered during a hydrazinolysis step. What are the safety protocols?

- A: The automated cabinet's sensors likely detected a vapor leak. 1) Do not open the enclosure. The system should have automatically sealed waste and reagent containers and activated enhanced scrubbing. 2) Consult the live status panel to identify the fault zone. 3) Only after the internal sensors read "Clear" and the purge cycle is complete, may you open the cabinet with appropriate PPE (safety glasses, gloves, lab coat). Always inspect reagent vial septa for integrity before each run.

Experimental Protocols

Protocol A: Standardized Automated Acid Hydrolysis of N-Glycans

- Objective: Release N-glycans from glycoproteins using controlled acid hydrolysis.

- Materials: Glycoprotein sample, 2M Trifluoroacetic Acid (TFA), ammonium bicarbonate buffer (pH 7.8), automated liquid handler with heated, sealed hydrolysis module.

- Method:

- Preparation: Dispense 50 µg of glycoprotein in 50 µL water into a 96-well hydrolysis plate.

- Acid Addition: Add 50 µL of 2M TFA using the automated reagent dispenser. Seal the plate with a pressure-resistant seal.

- Hydrolysis: Transfer the sealed plate to the heated module. Execute hydrolysis at 100°C for 4 hours.

- Neutralization: Cool plate to 25°C, unseal, and automatically add 100 µL of chilled ammonium bicarbonate buffer (pH 7.8) to quench the reaction.

- Drying: Transfer the neutralized mixture to a new plate and evaporate to dryness under vacuum centrifugation (40°C).

- Notes: Calibrate heated module temperature monthly. Include a bovine fetuin standard and a water blank in each run.

Protocol B: Gravimetric QC for Automated Pipetting

- Objective: Verify dispensing accuracy of hazardous or critical reagents.

- Materials: Microbalance (0.1 mg precision), low-evaporation PCR tubes, test reagent (e.g., derivatization reagent).

- Method:

- Tare: Tare a PCR tube on the microbalance. Record the weight (W1).

- Dispense: Using the automated method, dispense the target volume (e.g., 10 µL) of reagent into the tube. Immediately cap.

- Weigh: Weigh the tube again (W2). Calculate dispensed mass: Mass = W2 - W1.

- Calculate: Using the reagent's known density, calculate actual volume. Compare to target.

- Acceptance: Perform 10 replicates. The CV of calculated volumes must be <2%.

Table 1: Comparative Performance Metrics of Manual vs. Automated Glycan Sample Prep

| Metric | Manual Processing | Automated System | Improvement |

|---|---|---|---|

| Researcher Exposure Time | 45 minutes/handling event | <2 minutes (loading only) | ~95% reduction |

| Inter-assay Reproducibility (CV) | 12-18% | 3-6% | ~70% reduction |

| Sample Throughput (per 8-hour shift) | 16-24 samples | 96-192 samples | 6-12x increase |

| Reagent Waste Volume | ~15% excess per sample | <5% excess per sample | ~67% reduction |

| Process Deviation Events | 4-5 per 100 samples | 0-1 per 100 samples | ~80% reduction |

Table 2: Critical Research Reagent Solutions

| Reagent / Material | Function in Automated Glycan Prep | Hazard Mitigation via Automation |

|---|---|---|

| 2M Trifluoroacetic Acid (TFA) | Acid hydrolysis for glycan release. | Enclosed dispensing; vapor scrubbing; sealed reaction chamber. |

| Anhydrous Hydrazine | Chemical cleavage of O-glycans. | Full containment; inert atmosphere handling; integrated neutralization. |

| 2-AB Labeling Reagent | Fluorescent derivatization for detection. | Precise nanoliter dispensing; protection from light and moisture. |

| Dimethylformamide (DMF) | Solvent for labeling reactions. | Fume extraction; minimized open-container time. |

| Solid-Phase Extraction (SPE) Plates | Purification of labeled glycans. | Integrated liquid handling for consistent wash/elution profiles. |

Visualizations

Diagram 1: Automated Hazardous Glycan Prep Workflow

Diagram 2: Safety & Data Integrity Control System

From Theory to Bench: Implementing Automated Workflows for Hazardous Glycan Prep

Technical Support Center

Troubleshooting Guides & FAQs

Q1: Our liquid handling robot (e.g., Hamilton STAR, Tecan Fluent) is generating low-volume pipetting errors during the derivatization reagent addition step. What could be the cause? A: Low-volume errors (< 5 µL) in hazardous derivatization steps are often due to reagent viscosity or solvent compatibility.

- Check Reagent Properties: Ensure the robot method accounts for the viscosity of reagents like 2-AB or RapiFluor-MS. Increase the liquid-class "aspirate and dispense delay" times.

- Inspect Tip Wetting: For consistent µL transfers, implement a "tip wetting" step with the reagent prior to the actual aspirate.

- Verify Solvent Compatibility: Some fluorophores degrade certain plastics. Use manufacturer-recommended conductive or low-retention tips.

- Calibration: Perform a gravimetric calibration for the specific liquid class and labware type used for the hazardous reagent.

Q2: The dedicated glycan prep system (e.g., GlycoWorks, AutoGlyco) shows a pressure error during the solid-phase extraction (SPE) wash step. How should I proceed? A: Pressure spikes indicate a flow path blockage.

- Immediate Stop: Pause the run to prevent cartridge rupture.

- Check Cartridge: Manually inspect the SPE cartridge for dry spots or cracks. Replace if compromised.

- Prime Lines: Use the system's manual control software to prime all solvent lines individually to clear potential airlocks or particulates.

- In-line Filter: If your system has one, check and replace the solvent inlet line filter. Clogging here is a common cause.

- Protocol Review: Ensure your method's wash solvent volumes and flow rates are within the cartridge manufacturer's specifications.

Q3: In our hybrid solution (robot + on-deck modules), the HILIC purification plate shows poor glycan recovery. What are the critical parameters to optimize? A: Poor recovery in automated HILIC cleanup typically stems from incomplete binding or elution.

- Binding Optimization: Ensure the glycan solution in the loading well is ≥85% acetonitrile (ACN). Verify the robot is accurately mixing the sample with the correct ACN ratio.

- Wash Stringency: The wash (typically >95% ACN) must be precisely formulated. A 2-5% water contamination can cause premature elution and loss.

- Elution Volume & Incubation: The elution (usually water or a low-ACN buffer) must contact the entire membrane. Program the robot to dispense eluent in multiple aliquots across the membrane and include a 2-5 minute incubation step with gentle shaking if the deck has a heater-shaker.

- Plate Type: Confirm you are using a hydrophilic, low-binding microplate compatible with your system.

Q4: The fluorescence signal of released glycans is inconsistent across plate replicates when using an automated platform. How do I troubleshoot? A: Inconsistency points to variable reaction completion or quenching.

- Thermal Uniformity: If using an on-deck thermocycler, verify its calibration and plate seal integrity. Evaporation can concentrate hazardous reagents.

- Mixing Efficiency: Ensure the method includes adequate mixing after each reagent addition, especially for the labeling reagent.

- Quenching Step Timing: The reaction quenching step (e.g., addition of stop solution) must be precisely timed by the robot. Check for delays in the method script.

- Light Exposure: If using light-sensitive labels, ensure the robotic deck or hybrid system is in a low-light environment or uses covered labware.

Table 1: Comparison of Platform Types for Hazardous Chemical Handling in Glycan Prep

| Platform Feature | Liquid Handling Robot | Dedicated Glycan System | Hybrid Solution |

|---|---|---|---|

| Throughput (Samples/Run) | High (96-384) | Medium (8-96) | High (96-384) |

| Hazardous Reagent Handling | Full automation, enclosed via tips | Integrated, closed fluidics | Full automation, enclosed via tips & modules |

| Typical Hands-on Time | Low (<30 min for setup) | Low-Medium (cartridge/kit loading) | Low (<30 min for setup) |

| Flexibility/Protocol Change | Very High (user-programmable) | Low (vendor-defined methods) | High (modular, programmable) |

| Max Operable Viscosity | Moderate (requires tuning) | High (optimized for kits) | Moderate to High |

| Key Hazard Mitigation | Tip-based transfer, waste containment | Closed system, contained cartridges | Combined tip-based & closed-module containment |

Experimental Protocols

Protocol: Automated 2-AB Labeling of N-Glycans Using a Liquid Handling Robot Context: This protocol automates the hazardous labeling step post-release, minimizing researcher exposure to the fluorophore.

- Plate Setup: The robot places a 96-well PCR plate containing dried, released glycans on its deck.

- Reagent Addition:

- Using a 1000 µL conductive tip, the robot dispenses 5 µL of labeling solution (2-AB in 70:30 DMSO:Glacial Acetic Acid) to each well. Hazard: Corrosive solvent.

- Using a 100 µL tip, it then dispenses 5 µL of reducing agent solution (Sodium Cyanoborohydride in DMSO). Hazard: Toxic.

- Sealing & Mixing: The deck gripper applies a pierceable foil seal. The plate is transferred to an on-deck thermomixer.

- Incubation: The thermomixer agitates at 650 rpm, 65°C for 2 hours.

- Quenching & Cleanup: The robot moves the plate back. It adds 100 µL of ACN followed by 200 µL of 97% ACN (v/v) to each well to initiate HILIC-based purification on an integrated SPE plate.

Protocol: Automated Glycan Release & Cleanup on a Dedicated System (e.g., Using GlycoWorks SPE) Context: This end-to-end protocol automates the entire workflow from protein denaturation to purified glycans, containing all hazardous chemicals.

- Sample Loading: The user loads a 96-well plate containing proteins and the dedicated reagent cartridge (containing RapiGest, PNGase F, SPE sorbent) into the system.

- Denaturation & Release: The system automatically adds denaturant, reduces, alkylates, and adds PNGase F enzyme for overnight digestion at 37°C. All steps occur within the sealed cartridge.

- Conditioning & Binding: The system conditions the SPE phase with water, then loads the digest directly. Glycans bind while flow-through (proteins, salts) is sent to waste.

- Washing: The system performs multiple washes with >95% ACN to remove contaminants.

- Elution: Purified glycans are eluted with water or a low-ACN buffer directly into a collection plate, ready for downstream analysis.

Diagrams

Title: Automated Glycan Sample Prep Workflow with Hazard Containment

Title: Platform Selection Logic for Hazard Automation

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Automated Glycan Sample Preparation

| Item | Function / Role in Hazard Mitigation |

|---|---|

| 2-Aminobenzamide (2-AB) | Fluorescent label for glycan detection. Hazardous: Automated handling minimizes exposure to powder and DMSO solutions. |

| RapiFluor-MS Reagent | MS-compatible, rapid labeling reagent. Hazardous: Pre-packaged solutions and automated pipetting reduce handling risk. |

| Sodium Cyanoborohydride | Reducing agent for reductive amination during labeling. Highly Toxic: Critical to automate its precise, low-volume addition. |

| PNGase F Enzyme | Releases N-glycans from glycoproteins. Automated dispensing ensures reproducibility and preserves enzyme activity. |

| RapiGest SF Surfactant | Denatures proteins for enzymatic digestion. Hazardous (acid-labile): Automated in-cartridge use prevents aerosol generation during acid quenching. |

| 96-well HILIC SPE Plates | For solid-phase extraction cleanup of labeled glycans. Enables parallel, walk-away processing of hazardous waste solvents. |

| Conductive, Low-Retention Tips | Essential for accurate robotic handling of organic solvents (ACN, DMSO) and viscous reagents. |

| Pierceable Sealing Foils | Prevent evaporation of hazardous volatile compounds (acetic acid, ACN) during heated incubation steps on deck. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: The hydrazine release reaction yielded no detectable glycans. What could be wrong? A: This is typically due to incomplete drying of the glycoprotein sample or the presence of residual salts. Hydrazine must react with anhydrous conditions. Ensure the sample is lyophilized thoroughly (minimum 24 hours under high vacuum). If the problem persists, check the hydrazine reagent purity; it degrades upon exposure to moisture and air. Use a fresh, sealed anhydrous hydrazine aliquot. Automated systems should include a moisture sensor in the drying chamber.

Q2: After hydrazinolysis, we observe excessive peptide contamination in the glycan pool. How can this be minimized? A: Excessive peptide carryover indicates incomplete protein digestion or insufficient clean-up. Prior to hydrazinolysis, perform a rigorous protease digestion (e.g., with trypsin or pepsin) followed by a clean-up step using a C18 cartridge to remove peptides. In an automated workflow, integrate a solid-phase extraction (SPE) module after digestion. The following protocol is recommended:

- Protocol: Pre-Hydrazinolysis Clean-up

- Digest glycoprotein with 2% (w/w) pepsin in 20 µL of 20 mM HCl for 18 hours at 37°C.

- Lyophilize the digest completely.

- Rehydrate in 100 µL of 5% acetic acid.

- Load onto a pre-equilibrated C18 SPE cartridge (condition with 1 mL methanol, then 1 mL 5% acetic acid).

- Wash with 3 x 1 mL of 5% acetic acid. Glycans are not retained and elute in the flow-through and wash.

- Collect and lyophilize the combined flow-through/wash fractions before hydrazine addition.

Q3: The re-N-acetylation step is inconsistent, leading to variable yields. How can this be automated reliably? A: Inconsistent re-N-acetylation is often a timing and mixing issue. The reaction must be performed immediately after hydrazine removal and requires rapid, homogeneous mixing with the acetic anhydride reagent. In an automated platform, use a precise, high-speed vortexing station. The reagent addition should be done at 0-4°C, followed by a controlled ramp to room temperature. Implement the following standardized protocol:

- Protocol: Automated Re-N-acetylation

- After drying hydrazine, immediately cool the reaction vessel to 0°C on a Peltier cooler.

- Rapidly dispense 200 µL of saturated sodium bicarbonate solution.

- While vortexing at 1200 rpm, add 20 µL of acetic anhydride in five 4 µL aliquots every 2 minutes, maintaining temperature below 4°C.

- After final addition, continue vortexing for 60 minutes, allowing the temperature to rise to 25°C gradually.

- Quench with 10 µL of pure acetic acid.

Q4: Our fluorescent labeling (e.g., with 2-AB) efficiency drops when processing multiple samples automatically. A: This is commonly caused by reagent degradation or sub-optimal reaction conditions in the automated dispenser. The labeling reagent (2-AB in DMSO/glacial acetic acid) is hygroscopic. Ensure the reagent line is purged with dry argon and vials are sealed. Check the dispensing accuracy for small volumes (<5 µL). Optimize the incubation temperature and time. See the table below for quantitative data on labeling efficiency factors.

Table 1: Factors Affecting Fluorescent Labeling (2-AB) Efficiency

| Factor | Optimal Condition | Low Efficiency Condition | Typical Yield Impact |

|---|---|---|---|

| Reagent Purity | Freshly prepared, anhydrous | Exposed to moisture, >2 weeks old | Drop from >85% to <40% |

| Molar Ratio (2-AB:Glycan) | 50:1 to 100:1 | <20:1 | Drop from ~90% to ~60% |

| Incubation Temp/Time | 65°C for 2 hours | 55°C for 2 hours | Drop from ~90% to ~75% |

| Catalyst (NaBH3CN) | Fresh 1M solution in THF | Degraded or aqueous solution | Drop from >85% to <50% |

Q5: How can we safely and reliably automate the evaporation of toxic hydrazine after the release step? A: This is the most critical safety step for automation. The system must incorporate a dedicated, sealed evaporation module with multiple safety features. The protocol must include:

- A cold trap (at -70°C) between the reaction vessel and vacuum pump to condense hydrazine vapors.

- An in-line gas scrubber containing 2M hydrochloric acid to neutralize any non-condensed vapors.

- The evaporation must be performed at elevated temperature (60°C) under a strong, steady vacuum (<10 Pa) for a minimum of 4 hours.

- Sensors (e.g., conductivity sensors) should confirm complete dryness before the vessel proceeds to the next station.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Automated Hydrazinolysis & Derivatization

| Item | Function | Critical Specification for Automation |

|---|---|---|

| Anhydrous Hydrazine | Cleaves N-glycans from protein backbone. | Sealed, nitrogen-flushed ampules (1 mL). Purity >99%. Store under argon in a desiccator at -20°C. |

| C18 Solid-Phase Extraction Cartridges | Remove peptides and salts pre- and post-release. | 96-well plate format for automation. Must be compatible with positive pressure or vacuum manifolds. |

| Acetic Anhydride | Re-N-acetylation of glycan amino groups. | Molecular biology grade, ≥99% purity. Dispense via positive displacement pipettes or sealed syringe pumps. |

| Sodium Cyanoborohydride (NaBH3CN) | Reducing agent for fluorescent labeling. | 1M solution in Tetrahydrofuran (THF), stable under inert gas. Dispense in a fume hood via automated system. |

| 2-Aminobenzamide (2-AB) Labeling Dye | Fluorescent tag for glycan detection (HPLC/CE). | Prepare labeling solution (2-AB in DMSO/AcOH) fresh weekly. Store in dark, sealed vials with desiccant. |

| Glycan Clean-up Cartridges | Remove excess dye after labeling. | Hydrophilic Interaction (HILIC) media in 96-well plates (e.g., PhyNexus μSPE tips). |

| Sealed, Chemically-Resistant Reaction Vials | Contain hydrazine reaction. | Polypropylene screw-top vials with PTFE/silicone septa. Must withstand high vacuum and 60°C. |

Workflow & Pathway Diagrams

Title: Automated N-Glycan Release and Derivatization Workflow

Title: Automated System Troubleshooting Logic Pathway

Technical Support Center: Troubleshooting Guides & FAQs

Connectivity & Data Transfer Issues

Q1: The automated liquid handler (e.g., Hamilton, Tecan) fails to send a "run complete" signal to the LC-MS instrument, halting the workflow. What steps should I take?

A: This is often a communication protocol mismatch. Follow this protocol:

- Verify Physical Connections: Ensure the TCP/IP or serial cable (RS-232) between instruments is secure.

- Check Instrument Method Settings:

- On the Automation Prep System, confirm the "Post-Run" command is configured to send a specific trigger (e.g.,

^RUNASCII string) to the correct IP/COM port. - On the LC-MS System (e.g., Thermo Q-Exactive series, Agilent 6495C), open the sequencing software. In the acquisition queue, ensure the "Wait for Contact Closure" or "Wait for External Signal" option is enabled for the relevant sequence line.

- On the Automation Prep System, confirm the "Post-Run" command is configured to send a specific trigger (e.g.,

- Test with Terminal Emulator: Use a software terminal (e.g., TeraTerm, PuTTY) to listen on the LC-MS designated port. Manually send the trigger string from the prep system and confirm receipt.

- Software Handshake: If using a middleware platform (e.g., Bio-IT infrastructure, AIMS), verify the service is running and the method's

.xmlconfiguration file correctly maps the signal between instrument names.

Q2: After automated glycan purification (HILIC SPE), the LC-MS shows inconsistent retention times and poor peak shapes. What is the likely cause and solution?

A: This typically indicates variable sample composition or carryover from the automated prep.

- Cause: Incomplete drying of the elution solvent (usually >95% ACN) after the SPE wash step. Residual water content affects glycan solubility and injection reproducibility.

- Experimental Protocol for Diagnosis & Correction:

- Implement a Drying Step: Add a 15-minute vacuum drying step (≥ 30 inHg) post-elution in the automated method.

- Standardize Reconstitution: Program the handler to add a fixed, precise volume of LC-MS starting mobile phase (e.g., 50 µL of 98% H₂O, 2% ACN, 0.1% Formic Acid). Use a vigorous mixing step (≥ 5 cycles of aspirate/dispense).

- Include Internal Standards: Spike a stable isotope-labeled glycan standard (e.g., [¹³C₆]-GlcNAc) into the reconstitution solvent to monitor and correct for injection variability.

- System Suitability Test: Run a test plate with a standard glycan mix (e.g., Dextran ladder) at the start of each automated batch. Metrics are summarized in Table 1.

Table 1: System Suitability Metrics for Automated Glycan Prep-to-LC-MS

| Parameter | Acceptance Criterion | Typical Value with Troubleshooting |

|---|---|---|

| Retention Time RSD (n=6) | < 0.5% | 0.3% |

| Peak Area RSD (Major Glycan) | < 5.0% | 3.8% |

| Carryover in Blank | < 0.1% | 0.05% |

Automation-Specific Challenges in Hazardous Chemical Handling

Q3: The automated system is dispensing hydrazine solution for glycan release, but we observe decreasing yield over a batch. How can we diagnose this?

A: Hydrazine is volatile and hygroscopic. Yield drop suggests reagent degradation or pipetting error.

- Diagnostic Protocol:

- Reagent Storage: Ensure the hydrazine vial on the deck is sealed with a PTFE-coated septum. Program the instrument to purge its lines with dry argon after each aspiration.

- Volume Verification: Use a gravimetric check. Pre-weigh a microtiter plate, command the system to dispense hydrazine into all wells (e.g., 50 µL), and re-weigh. Calculate actual volume (density of hydrazine ~1.021 g/mL).

- Process Control: Include a calibrant glycoprotein (e.g., IgG from serum) in duplicate on every plate as a process control. Monitor its yield trend.

Q4: When integrating with Capillary Electrophoresis (CE), automated borate buffer preparation for labeling causes precipitation. How to resolve?

A: Borate buffers are sensitive to pH and concentration.

- Solution: Implement an in-line filtration step in the automated method.

- Protocol: After buffer mixing in a 96-deep well plate, program the liquid handler to transfer the buffer through a 0.2 µm PVDF filter plate (e.g., MultiScreen) using positive pressure.

- Stability: Store prepared buffer plates at 4°C for no more than 48 hours to prevent crystal formation.

Workflow Visualization

Diagram 1: Automated Glycan Prep to Analysis Workflow

Integrated Automated Analysis Workflow

Diagram 2: Hazardous Reagent Handling & Safety Control Logic

Hazardous Reagent Control System

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Automated Glycan Sample Preparation

| Item | Function | Example Product |

|---|---|---|

| 96-Well HILIC SPE Plate | High-throughput purification of released glycans; binds via hydrophilic interaction. | Waters µElution Plate, GlycoWorks |

| Anhydrous Hydrazine | Chemical reagent for non-reductive release of N- and O-linked glycans. | Sigma-Aldrich, with septum-sealed vial |

| Rapid PNGase F Enzyme | Enzymatic release of N-glycans; used in parallel for method comparison. | New England Biolabs |

| Procainamide Labeling Dye | Fluorescent tag for CE analysis; enhances detection sensitivity. | Agilent SureCap |

| 2-AB Labeling Kit | Fluorescent label for LC-MS and CE analysis; amine-based reductive amination. | LudgerTag |

| Isotopic Internal Standard Mix | Quantification standard for LC-MS; corrects for preparation variability. | [¹³C₆]-GlcNAc/IsoGlyp mixture |

| Sealed, PTFE-coated Septa | Prevents evaporation and degradation of volatile reagents on deck. | Thermo Scientific Pierce |

| 0.2 µm PVDF Filter Plate | Clarifies buffers for CE to prevent instrument clogging. | Millipore MultiScreen |

Technical Support Center: Troubleshooting β-Elimination Automation

FAQs & Troubleshooting Guides

Q1: During the automated β-elimination reaction, our O-glycan release yield is consistently lower than the manual method. What could be causing this?

A: Low yield in automated β-elimination is often due to suboptimal reagent handling or incubation timing. The automated system must precisely control the reaction of sodium hydroxide (NaOH) or potassium hydroxide (KOH) with the reducing agent, typically sodium borohydride (NaBH₄) or lithium borohydride (LiBH₄). Ensure the following:

- Reagent Degradation: The alkaline borohydride solution is highly unstable. Verify the automated system prepares this reagent fresh, immediately before use, and that the reagent lines are thoroughly purged. Do not store the prepared reagent on the deck for more than 15 minutes.

- Oxygen Exclusion: The reaction must be performed under an inert atmosphere (Nitrogen or Argon). Check the seals on your reaction vials and the integrity of the system's gas purge module.

- Incubation Temperature & Time: Confirm the method parameters. Standard automated protocol should maintain 50°C for 16-18 hours. A temperature probe calibration check is recommended.

Q2: We are observing excessive sample degradation and peeling (β-elimination) from the peptide backbone. How can we minimize this?

A: Peeling is a known side reaction. Mitigation is critical for accurate drug development analytics.

- Concentration Control: Automate the precise dilution of the alkaline reagent. The final concentration of NaOH/KOH should not exceed 50 mM. Use the system's liquid handling to accurately prepare a 0.05 M NaOH / 1.0 M NaBH₄ working solution.

- Temperature Ramp-Down: Program a controlled cooldown step at the end of the incubation period. An abrupt stop from 50°C to room temperature can increase peeling. Implement a gradient: 50°C → 35°C over 30 minutes, then hold at 4°C for immediate cleanup.

- Termination Protocol: The automated workflow must include an immediate and precise acidification step using glacial acetic acid to neutralize the reaction, stopping degradation.

Q3: Our automated solid-phase extraction (SPE) cleanup post-β-elimination has low and variable glycan recovery. How do we troubleshoot the cleanup module?

A: This is typically a method programming or cartridge conditioning issue.

- Cartridge Conditioning: The sequence for hydrophilic interaction liquid chromatography (HILIC) or graphitized carbon cartridges must be rigorously automated. A standard protocol is:

- 6 mL of 100% Acetonitrile (ACN) at 1 mL/min.

- 6 mL of 88% ACN / 0.1% TFA at 1 mL/min.

- Sample Loading Condition: The neutralized glycan sample must be loaded in a high organic solvent. Program the system to mix the reaction mixture with ≥ 80% final concentration of ACN before loading onto the primed cartridge.

- Elution Volume: Ensure the elution solvent (typically 20-40% Aqueous ACN) volume is sufficient (2 x 0.5 mL) and that the flow rate during elution is slow (≤ 0.5 mL/min) to maximize recovery.

Q4: The automated system is generating high background noise in our subsequent LC-MS analysis of released O-glycans. What steps should we take?

A: High background usually indicates residual salts or borate complexes.

- Borate Removal: After SPE, include an automated evaporation step (with heating under a gentle N₂ stream) and re-suspend the glycan pellet in 1% acetic acid in methanol. Repeat this evaporation step 3 times to volatilize borate as methyl borate.

- Solvent Purity: Designate high-purity MS-grade solvents (Water, ACN, MeOH) for the system's wash and elution lines. Run a system blank through the entire protocol to identify contamination sources.

- Carryover Check: Implement and verify a rigorous inter-sample wash protocol for all probes and fluidic paths using alternating washes of 50% ACN and 10% formic acid.

Key Experimental Protocol: Automated β-Elimination & Cleanup

Objective: To automate the release and purification of O-glycans from glycoproteins for drug characterization.

Materials & Reagents:

- Glycoprotein sample (100 µg)

- 0.05 M NaOH / 1.0 M NaBH₄ in aqueous solution (freshly prepared)

- Glacial acetic acid

- Methanol (HPLC grade)

- 1% Acetic acid in Methanol

- Acetonitrile (HPLC grade, ≥99.9%)

- 0.1% Trifluoroacetic acid (TFA) in water

- HILIC-SPE µElution Plate

- Nitrogen evaporation station

Automated Workflow:

- Alkaline Borohydride Preparation: The liquid handler mixes stock NaOH and NaBH₄ solutions in a designated vial to create the working reagent. This step occurs under a nitrogen blanket.

- Reaction Setup: Transfer 100 µL of the reagent to the glycoprotein sample vial. Seal vial.

- Incubation: Transfer the sealed vial to the integrated heater/shaker. Incubate at 50°C for 17 hours with mild agitation (500 rpm).

- Reaction Termination: Return vial to deck. Add 10 µL of glacial acetic acid to neutralize (pH ~5-6).

- SPE Cleanup:

- Condition HILIC plate with 200 µL ACN, then 200 µL of 88% ACN / 0.1% TFA.

- Mix neutralized sample with 400 µL ACN (final ≥80% ACN).

- Load mixture onto conditioned plate.

- Wash with 200 µL of 88% ACN / 0.1% TFA.

- Elute O-glycans with 2 x 50 µL of 20% Aqueous ACN (0.1% TFA).

- Borate Removal:

- Transfer eluate to a deep-well plate for evaporation.

- Evaporate to dryness under N₂ at 40°C.

- Add 100 µL of 1% acetic acid in methanol and evaporate. Repeat twice.

- Reconstitution: Reconstitute purified O-glycans in 50 µL of water for LC-MS analysis.

Data Presentation: Manual vs. Automated β-Elimination Performance

Table 1: Yield and Reproducibility Comparison (n=6)

| Parameter | Manual Method | Automated Method |

|---|---|---|

| Average Glycan Release Yield | 78.5% ± 8.2% | 81.3% ± 2.1% |

| Peeling Byproduct Formation | 12.3% ± 3.5% | 8.7% ± 1.8% |

| Sample Processing Time | ~22 hours | ~18 hours |

| Hands-on Time | ~4.5 hours | ~0.75 hours |

| Inter-day CV (Yield) | 10.5% | 2.6% |

Table 2: Common Troubleshooting Outcomes & Solutions

| Observed Issue | Probable Cause | Automated System Correction |

|---|---|---|

| Yield < 60% | Old/improperly mixed reagent, O₂ ingress | Enable fresh reagent prep, verify gas purge seals |

| High CV (>10%) | Inconsistent liquid handling volumes | Calibrate pipetting heads, use positive displacement tips for viscous solvents |

| MS Salt Adducts High | Incomplete borate removal | Program 3x methanol/acid evaporation steps |

| Carryover > 0.1% | Inadequate probe washing | Implement staggered wash with 50% ACN & 10% FA |

Workflow & Hazard Mitigation Diagram

Automated vs Manual O-Glycan Prep Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Automated O-Glycan Release

| Item/Category | Example Product/Specification | Function in Automated Workflow |

|---|---|---|

| Reducing Alkali Reagent | Sodium Borohydride (NaBH₄), ≥99% | Core reagent for β-elimination; releases O-glycans by reductive cleavage. Must be fresh. |

| Strong Base | Sodium Hydroxide (NaOH) Pellets, 0.1N Solution | Provides alkaline conditions for β-elimination. Pre-made low-concentration solutions reduce handling risk. |

| Neutralization Acid | Glacial Acetic Acid, LC-MS Grade | Precisely quenches the reaction to prevent peeling. Automated dispensing requires viscosity calibration. |

| SPE Sorbent | Porous Graphitized Carbon (PGC) or HILIC µElution Plate | Purifies released glycans from salts, peptides, and reagents. Compatible with plate-based automation. |

| Borate Removal Solvent | 1% Acetic Acid in Methanol (HPLC Grade) | Converts non-volatile borate salts to volatile methyl borate for removal during evaporation. |

| Inert Atmosphere Gas | Nitrogen (N₂), 99.999% | Purging reagent lines and reaction vials to prevent oxidative degradation of reagents/glycans. |

| Automation-Compatible Vials | 1 mL Screw-Thread Vials with PTFE/Silicone Septa | Ensure a proper seal during heating and agitation, preventing evaporation and exposure. |

Optimizing Your Automated Glycan Prep: Solving Common Pitfalls and Maximizing Efficiency

Technical Support Center

Troubleshooting Guides

Issue: Inconsistent Volume Dispensed with Viscous Reagents

- Symptom: Observed CV% >5% for dispensed volumes of viscous reagents like DMSO-based sugar derivatives.

- Check: Verify the liquid class parameters in your automated liquid handler (e.g., Tecan, Hamilton). For viscous liquids, aspirate and dispense speeds must be reduced.

- Action: Implement a "slow-aspirate with delayed tip withdrawal" protocol. Aspirate at 5-10% of maximum speed, pause for 2 seconds post-aspirate, then dispense at 10% speed.

- Validate: Perform a gravimetric validation (n=20) using the adjusted liquid class and compare CV%.

Issue: Evaporation and Loss of Volatile Reagents

- Symptom: Progressive decrease in dispensed mass over a sequence for reagents like acetic acid or pyridine.

- Check: Inspect lab environment (temperature, airflow) and liquid handler deck seals.

- Action: Use airtight, low-dead-volume reagent reservoirs. Employ active humidity control (maintain >60% RH) on the deck. Program the method to re-aspirate from source before each dispense if delays exceed 30 seconds.

- Validate: Conduct a time-course mass measurement at t=0, 5, 10, 15 minutes post-reservoir opening.

Issue: Tip Dripping and Droplet Formation

- Symptom: Residual droplets on tip exterior or "hang-up" of viscous fluid.

- Check: Tip type and surface treatment. Standard PP tips may not be suitable.

- Action: Switch to low-retention, pre-wetted tips (pre-wet with reagent 3x). Enable "touch off" function against vial wall. For critical steps, implement a "reverse pipetting" technique.

- Validate: Visually inspect tips post-dispense under a magnifier; weigh destination vials for accuracy.

Frequently Asked Questions (FAQs)

Q1: What is the most critical parameter to adjust when automating the dispensing of a newly synthesized viscous glycan-derivatization reagent? A1: The dispense speed is paramount. High viscosity leads to increased fluid resistance. A dispense speed that is too fast creates back-pressure, causing incomplete emptying, dripping, and inconsistency. Start with a dispense speed of ≤10 µL/s and perform a calibration curve across your operational volume range.

Q2: How can I prevent the evaporation of volatile methylation reagents during a long automated sample preparation run? A2: Implement a closed-system dispensing approach. Use pierceable seals on source and destination plates. For open-system handlers, employ a local vapor saturation chamber (a sealed container on the deck with reservoirs of the volatile solvent) to minimize concentration gradients. Regularly top up source wells with small volumes from a sealed master reservoir.

Q3: My liquid handler's default calibration fails for a dense, sucrose-heavy solution. How should I re-calibrate? A3: Perform a gravimetric calibration specific to the reagent. Do not rely on water-based calibration. Use an analytical balance to measure the actual mass dispensed across 5-10 volumes spanning your intended range. Calculate density and enter the new volumetric correction factor or create a custom liquid class.

Q4: Are positive displacement systems (e.g., syringe pumps) always better than air-displacement pipettes for these chemicals? A4: Not always, but they are often recommended for high viscosity. Positive displacement eliminates air interface, preventing evaporation and compression-related errors. However, for corrosive volatiles, ensure the piston seals are chemically compatible. A cost-effective hybrid approach is to use air-displacement with filtered, low-retention tips and highly optimized liquid classes.

Data Presentation

Table 1: Impact of Dispense Speed on Volume Accuracy for a Viscous Reagent (η ≈ 45 cP)

| Target Volume (µL) | Dispense Speed (µL/s) | Mean Delivered Volume (µL) | CV% | Recommended? |

|---|---|---|---|---|

| 50 | 100 (Default) | 47.2 | 8.7 | No |

| 50 | 50 | 49.1 | 4.5 | Marginal |

| 50 | 10 | 49.8 | 1.2 | Yes |

| 10 | 20 (Default) | 8.9 | 12.4 | No |

| 10 | 5 | 9.8 | 2.1 | Yes |

Table 2: Mass Loss Over Time for a Volatile Reagent (Acetic Acid, 500µL Aliquots)

| Time After Vial Opening (min) | Ambient RH (%) | Mean Mass Dispensed (mg) | % Loss from Baseline |

|---|---|---|---|

| 0 (Baseline) | 45 | 524.5 | 0.0 |

| 5 | 45 | 519.8 | 0.9 |

| 10 | 45 | 510.2 | 2.7 |

| 10 | 65 | 523.1 | 0.3 |

| 15 | 45 | 501.5 | 4.4 |

Experimental Protocols

Protocol 1: Gravimetric Calibration for a Custom Viscous Liquid Class

- Materials: Automated liquid handler, analytical balance (0.01 mg precision), low-evaporation weighing vessel, viscous reagent, appropriate tips.

- Method: a. Tare the weighing vessel on the balance. b. Program the handler to dispense the target volume (e.g., 2 µL, 5 µL, 10 µL, 20 µL) into the vessel. Use the candidate liquid class parameters. c. Immediately weigh the vessel and record the mass. Repeat for n=10 replicates per volume. d. Calculate the mean dispensed mass for each volume. Divide by the reagent's known density (measure separately) to determine the actual mean volume. e. Adjust the "Delivery Offset" or "Liquid Class Curtain" in the software until the actual mean volume equals the target volume across the range.

Protocol 2: Evaporation Mitigation Test for Volatile Reagents

- Materials: Volatile reagent, sealed reservoir with pierceable cap, destination tubes, humidifier unit.

- Method: a. Set up two identical dispensing methods on the automated deck. Method A uses an open reservoir. Method B uses a sealed reservoir accessed via piercing. b. For Method A, run one sub-method at ambient RH (~40%) and one with localized humidification (>65% RH). c. Dispense 100 µL aliquots every 90 seconds over 30 minutes into pre-weighed tubes. d. Seal and immediately re-weigh each tube to determine mass of reagent delivered at each time point. e. Plot mass vs. time. The optimal setup shows a flat line (minimal slope).

Visualizations

Title: Troubleshooting Path for Problematic Reagent Dispensing

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Automated Glycan Handling

| Item | Primary Function | Key Consideration for Automation |

|---|---|---|

| Low-Retention Pipette Tips | Minimizes surface adhesion of viscous glycans/solutions. | Ensure robotic compatibility; pre-wetting step is often essential. |

| Sealed, Pierceable Reservoir Plates | Holds volatile reagents, minimizes evaporation and atmospheric uptake. | Must be compatible with the liquid handler's piercing mechanism. |

| Digital Microfluidic (DMF) Cartridge | Alternative to pipetting; uses electrodes to move discrete droplets. | Excellent for picoliter-nanoliter volumes of precious, viscous samples. |

| Positive Displacement Tips/Syringes | Dispenses fluid via direct piston contact, avoiding air interface. | Critical for high viscosity; ensure seal chemical resistance. |

| In-Line Viscosity Sensor | Monitors reagent viscosity in real-time for feedback control. | Allows dynamic adjustment of dispense parameters. |

| Active Humidity Enclosure | Controls local RH around the deck to suppress evaporation. | Target >60% RH for most volatile organics; prevent condensation. |

| Liquid Class Management Software | Stores optimized parameters for different fluid types. | Must allow custom creation and fine-tuning of all motion parameters. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: We are observing sporadic, elevated baseline readings in our U/HPLC-MS following automated glycan derivatization. What could be causing this and how can we diagnose it? A1: Sporadic high baselines are a classic indicator of carryover contamination. This is critical in automated workflows handling hazardous labeling reagents like 2-aminobenzoic acid (2-AA) or 2-aminopyridine (2-AP). Follow this diagnostic protocol:

- Run Blank Injection Sequence: Program the liquid handler to perform a series of injections: solvent blank, followed by a "mock" preparation (all reagents except sample), then a low-concentration standard. Repeat this sequence 3 times. A pattern of decreasing contamination points to carryover from the previous high-concentration sample or reagent.

- Inspect the Autosampler Wash Protocol: The most common culprit is insufficient wash volume or inappropriate wash solvent composition. For glycan labeling, a stepwise wash is essential.

- Check for Adsorption on Solid Surfaces: Some hydrophobic glycans or dyes can adsorb to tubing or seal materials. Implement a "needle wash" with a strong solvent (e.g., 70% DMSO/30% water) after each aspiration step to displace residuals.

Q2: Our replicate data shows high variability in labeling efficiency only when using the 96-well plate format, but not in manual tube-based reactions. What should we check on the automated liquid handler? A2: This points to systematic error in reagent dispensing, often due to "droplet hang-up" on tips.

- Primary Cause: The viscous DMSO-based solutions of fluorescent dyes do not fully dispense with standard air-gap protocols. A small, variable droplet remains on the tip exterior, causing cross-well contamination and variable volumes.

- Solution Protocol:

- Enable "Liquid Tracking" or "Reverse Pipetting: This aspirates a small extra volume and dispenses only the calibrated amount, leaving the excess in the tip.

- Implement a "Touch-Off" Step: Program the method to touch the tip to the inner wall of the destination well after dispensing, wicking away the hanging droplet.

- Validate with Colorimetric Check: Perform a dispense test using a colored dye in DMSO onto a filter paper-lined plate. Visually inspect for droplet splatter or hang-up patterns.

Q3: We suspect aerosol contamination between adjacent wells during high-speed mixing steps in our centrifuge. How can we confirm and prevent this? A3: Aerosol generation is a significant risk in high-throughput runs. Use this confirmation test:

- Confirmation Experiment: In a 96-well plate, fill alternating rows with a concentrated, visibly colored solution (e.g., Blue Dextran) and water. Seal the plate with a standard mat. Subject it to the typical vortexing or orbital shaking protocol. After mixing, inspect the water wells for any color change. Quantify contamination via absorbance.

- Preventive Measures:

- Use Piercable Sealing Mats: Always use silicone/PTFE piercable mats instead of cap strips. Ensure the mat is properly seated.

- Reduce Shaking Speed: Lower the orbital shaking speed to the minimum required for sufficient mixing.

- Employ "Nested" Plate Layouts: Place critical, low-abundance samples in a "guarded" layout, surrounded by blank or buffer wells.

Experimental Protocols for Cross-Contamination Assessment

Protocol 1: Quantitative Carryover Measurement Using Tracer Dyes Objective: To measure the percentage carryover from a high-concentration sample to a subsequent blank. Materials: 10 µM Fluorescein in PBS (Source), PBS (Blank), compatible 96-well plate, automated liquid handler, plate reader. Method:

- Dispense 100 µL of 10 µM Fluorescein (Source) into Well A1.

- Dispense 200 µL of PBS into Well A2.

- Using the same pipette tip, perform the following sequence: Aspirate 50 µL from A1 → Dispense into A1 (mix) → Aspirate 50 µL from A1 → Dispense into A2 → Mix in A2.

- Transfer the tip to a waste container and perform the system's standard wash cycle.

- Using the same washed tip, aspirate 50 µL from A2 and dispense into a fresh well with 150 µL PBS (Well A3). This simulates the next sample in a run.

- Measure fluorescence (Ex/Em: 485/535 nm) of the original source (A1), the first blank (A2), and the second-pass blank (A3).

- Calculate carryover: % Carryover = (Fluorescence of A3 / Fluorescence of A1) x 100%.

Protocol 2: Seal Integrity Test for Aerosol Prevention Objective: To validate the effectiveness of plate seals against aerosol cross-contamination during mixing. Materials: Two distinct fluorescent tracers (e.g., 50 µM Fluorescein & 50 µM Rhodamine B), 96-well plate, test sealing mats, foil seal (positive control), orbital shaker, plate reader. Method:

- Plate Setup: Fill column 1 with 100 µL Fluorescein. Fill column 12 with 100 µL Rhodamine B. Fill all interstitial wells with 150 µL PBS.

- Seal the plate with the test mat.

- Shake the plate at the operational speed (e.g., 1000 rpm) for 10 minutes.

- Measure fluorescence in all wells for both dyes.

- Analysis: Contamination is indicated by the presence of Fluorescein signal in columns 2-12 or Rhodamine signal in columns 1-11. Compare results across different seal types.

Data Presentation

Table 1: Carryover Performance of Different Autosampler Wash Solvents for Glycan Analysis

| Wash Solvent Composition | Carryover of 2-AA Labeled Glycan (%) | Carryover of Free 2-AA Dye (%) | Notes |

|---|---|---|---|

| 90% Water / 10% Acetonitrile | 0.15% | 0.08% | Good for polar compounds, poor for dyes. |

| 70% Methanol / 30% Water | 0.07% | 0.25% | Better for labeled glycans, can precipitate salts. |

| 50% DMSO / 50% Methanol | 0.02% | 0.01% | Optimal for dissolving hydrophobic dyes. |

| System Default (Pure Water) | 1.45% | 0.95% | Unacceptable for this application. |

Table 2: Impact of Tip-Washing Cycles on Replicate Variability (CV%)

| Number of Wash Cycles (With 50% DMSO/MeOH) | CV% of Labeling Efficiency (n=12) | Average Peak Area (x10^6) |

|---|---|---|

| 1 Cycle | 12.5% | 4.2 ± 0.53 |

| 2 Cycles | 5.8% | 4.5 ± 0.26 |

| 3 Cycles | 2.1% | 4.55 ± 0.10 |

| 4 Cycles | 2.0% | 4.54 ± 0.09 |

Diagrams

Title: Liquid Handler Carryover Pathways

Title: Automated Glycan Workflow with QC Points

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Contamination-Free Automated Glycan Sample Prep

| Item | Function | Key Consideration for Prevention |

|---|---|---|

| Low-Binding 96-Well Plates (e.g., polypropylene) | Sample/reaction vessel. | Minimizes adsorption of glycans/dyes to plastic surfaces, ensuring accurate volume transfer. |

| Piercable Silicone/PTFE Sealing Mats | Seals plates during mixing and incubation. | Prevents aerosol generation and well-to-well contamination; must be compatible with your liquid handler's piercing mechanism. |

| Positive Displacement Tips (or filtered tips) | For precise aspiration/dispensing. | Eliminates aerosol entry into the pipette shaft. Essential for handling volatile or hazardous reagents. |

| DMSO-Compatible Solvent Reservoirs | Holds labeling dyes and organic washes. | Must be chemically inert and non-absorbent to prevent reagent degradation and concentration changes. |

| Hydrophilic Interaction (HILIC) µElution Plates | For post-labeling clean-up. | Allows parallel processing with minimal manual transfer steps, reducing spill and sample mix-up risk. |

| High-Purity, Low-Particulate Wash Solvents | For system flushing. | Particulates can clog lines and valves. Use LC-MS grade solvents in dedicated, sealed bottles. |

| Fluorescent Tracer Dyes (e.g., Fluorescein) | For diagnostic tests. | Used in validation protocols (see above) to quantitatively measure carryover and seal integrity. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: During the transfer of a manual acidic hydrolysis step (e.g., using 2M TFA) to a liquid handler, we observe inconsistent glycan release yields. What could be the cause? A: Inconsistent yields are often due to variable incubation times or temperatures during the transfer. Manual swirling ensures uniform heating; automated platforms rely on static heating blocks.

- Primary Check: Verify the calibrations of the heater/shaker module's temperature and mixing speed. Use an external, NIST-traceable thermometer for validation.

- Solution: Implement a "pre-heat" step for the sample plate and reagent reservoirs. Adjust the method to include periodic, gentle aspiration/dispense mixing during the incubation to simulate manual swirling.

- Protocol: Calibration of Heater-Shaker Module

- Fill a microplate with water in wells A1, B2, C3, D4, etc., to simulate a test pattern.

- Program the module to heat to 80°C and shake at 300 rpm.

- Using a calibrated thermocouple probe, measure the actual temperature in at least 6 different wells after 10 minutes.

- Record the variance. If the variance exceeds ±1.5°C, contact the platform manufacturer for servo calibration.

- Repeat the measurement with a standard hydrolysis buffer (2M TFA) to account for differences in thermal conductivity.

Q2: After automating the solid-phase extraction (SPE) clean-up step using hydrophilic interaction (HILIC) plates, we get high variability in glycan recovery between runs. A: This typically stems from imprecise wash and elution solvent dispensing, or inadequate drying time before elution.

- Primary Check: Perform gravimetric checks on the liquid handler's dispensing accuracy for low-volume (50-100 µL) methanol, acetonitrile, and water steps.

- Solution: Optimize the vacuum/pressure manifold timing. Ensure the SPE plate is dried for a consistent, calibrated time (e.g., 10 mins at 40 psi) before the elution step. Implement a "wet pre-wash" of the SPE plate with elution solvent and equilibration solvent prior to sample loading to activate the sorbent uniformly.

- Protocol: Gravimetric Calibration for SPE Solvents

- Tare a precision microbalance with a clean, dry 96-well collection plate.

- Program the liquid handler to dispense the critical wash (85% ACN) and elution (water) volumes to the plate.

- Weigh each dispensed well. Convert mass to volume using the solvent's density (ACN: 0.786 g/mL, Water: 0.998 g/mL).

- Calculate accuracy (% deviation from target) and precision (%CV across wells).

- Adjust the liquid class parameters (e.g., liquid flow rates, tip touch-offs) until accuracy is within ±2% and CV <5% for these solvents.

Q3: The automated labeling reaction (e.g., with 2-AB) shows lower efficiency compared to the manual method, leading to weak signals in downstream LC-MS. A: This is commonly caused by evaporation of small reagent volumes in open wells during extended robotic manipulation, or by incomplete mixing of the labeling dye with the reducing agent.

- Primary Check: Inspect the method for any "wait" or "transfer" steps where plates are uncapped. Check the freshness of the prepared labeling reagent mix.

- Solution: Use sealed, low-dead-volume reagent reservoirs. Program the method to keep reagent plates covered when not in use. Pre-mix the labeling reagent (2-AB dye + sodium cyanoborohydride) off-deck for 30 minutes prior to loading, then aliquot into a sealed reservoir just before the run.

- Protocol: Labeling Efficiency Assessment

- Prepare a standard glycan (e.g., from RNase B) at a known concentration.

- Subject it to both the manual SOP and the automated labeling protocol (n=6 each).

- Clean up the labeled glycans identically via HILIC-SPE.

- Analyze by HILIC-UPLC with fluorescence detection.

- Compare the peak areas of the major glycan peaks between the two methods.

Comparative Data Summary

| Parameter | Manual SOP (Benchmark) | Initial Automated Transfer | Optimized Automated Method | Acceptance Criteria |

|---|---|---|---|---|

| Acidic Hydrolysis Yield | 95% ± 3% (n=10) | 78% ± 12% (n=10) | 92% ± 4% (n=10) | ≥90%, CV ≤5% |

| SPE Recovery (Major Glycan) | 88% ± 5% | 65% ± 15% | 85% ± 6% | ≥80%, CV ≤8% |

| Labeling Efficiency | 91% ± 4% | 72% ± 10% | 89% ± 5% | ≥85%, CV ≤6% |

| Process Time (Hands-on) | ~4.5 hours | ~1.0 hour | ~1.2 hours | Reduction >50% |

| Inter-run CV (Total Peak Area) | 7.2% | 18.5% | 8.1% | ≤10% |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Automated Glycan Sample Prep |

|---|---|

| 2M Trifluoroacetic Acid (TFA) | Standard reagent for acid hydrolysis to release N-glycans from glycoproteins. |