Absolute Quantification of Glycans: A Comprehensive Guide to the Full Glycome Internal Standard Approach for MALDI-TOF-MS

This article provides a comprehensive guide for researchers and drug development professionals on implementing a full glycome internal standard approach for accurate, absolute quantification of glycans using MALDI-TOF-MS.

Absolute Quantification of Glycans: A Comprehensive Guide to the Full Glycome Internal Standard Approach for MALDI-TOF-MS

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on implementing a full glycome internal standard approach for accurate, absolute quantification of glycans using MALDI-TOF-MS. We cover the foundational principles of glycan analysis and why quantification is a major challenge. The methodological section details a step-by-step protocol for selecting, preparing, and using isotopically-labeled internal standards across the entire glycome. We address common troubleshooting issues in sample preparation, matrix selection, and spectral interpretation, offering optimization strategies for sensitivity and reproducibility. Finally, we validate the approach through comparative analysis with other techniques (like LC-MS and HPLC) and present data on accuracy, precision, and linear dynamic range. This guide aims to equip scientists with the knowledge to achieve robust, quantitative glycomics data for biomarker discovery and biotherapeutic development.

Why Quantify Glycans? Understanding the Challenge and Core Principle of Internal Standardization

Application Note AN-001: Full Glycome Internal Standard (FGIS) for Serum N-Glycan Quantification in Cancer Biomarker Discovery

Objective: To quantify alterations in the serum N-glycome associated with hepatocellular carcinoma (HCC) using a Full Glycome Internal Standard (FGIS) approach for MALDI-TOF-MS, enabling absolute quantification and inter-laboratory reproducibility.

Background: Glycosylation changes on serum proteins, such as increased branching and fucosylation, are hallmark events in HCC. Precise quantification of these changes is crucial for developing clinical biomarkers but is hampered by a lack of standardized quantification methods.

Experimental Protocol: FGIS-Enabled Serum N-Glycan Preparation for MALDI-TOF-MS

Step 1: Serum Protein Denaturation & Release.

- Dilute 10 µL of human serum with 90 µL of 50 mM ammonium bicarbonate buffer.

- Denature by adding 1 µL of 10% SDS and heating at 65°C for 10 min.

- Add 10 µL of 10% Igepal CA-630 to sequester SDS.

- Add 2 µL of recombinant PNGase F (500 U/µL) and incubate at 37°C for 18 hours.

Step 2: FGIS Addition and Glycan Cleanup.

- Add 10 µL of the FGIS Mixture (see Reagent Solutions) to the released glycan sample. This contains a known molar quantity of 13C-labeled, non-natural glycans covering major structural classes.

- Desalt and purify glycans using porous graphitized carbon (PGC) solid-phase extraction tips.

- Elute glycans with 40% acetonitrile containing 0.1% TFA, followed by 60% acetonitrile with 0.1% TFA. Combine eluates and dry in a vacuum concentrator.

Step 3: MALDI Target Preparation & Data Acquisition.

- Reconstitute glycans in 20 µL of ultrapure water.

- Spot 1 µL of sample mixed 1:1 with super-DHB matrix (20 mg/mL in 50% acetonitrile) onto a polished steel MALDI target.

- Acquire spectra in positive reflection mode on a MALDI-TOF/TOF instrument (e.g., Bruker ultrafleXtreme).

- Acquisition Parameters: Mass range: 1000-5000 Da; Laser frequency: 2000 Hz; 5000 shots summed per spectrum.

Step 4: Data Processing and Absolute Quantification.

- Process spectra (smoothing, baseline subtraction) using proprietary software (e.g., flexAnalysis).

- For each target native glycan peak ([M+Na]+), identify the nearest eluting FGIS glycan peak based on retention behavior in PGC-SPE (simulated by mass proximity in a defined window).

- Apply the response factor calculated from the FGIS standard to the native glycan peak intensity.

- Calculate absolute quantity using the formula:

[Glycan]_{abs} = (Peak Area_{Native} / Peak Area_{FGIS}) * [FGIS]_{known}

Results & Data Presentation:

Table 1: Absolute Quantification of Key Serum N-Glycans in HCC vs. Control Cohorts (n=50/group)

| Glycan Composition (HexNAc-Hex-Fuc-NeuAc) | Mean Quantity in Control (pmol/µL serum) | Mean Quantity in HCC (pmol/µL serum) | Fold Change (HCC/Control) | p-value |

|---|---|---|---|---|

| 4-5-1-0 (Core Fucosylated Triantennary) | 1.23 ± 0.31 | 3.87 ± 0.89 | 3.15 | <0.0001 |

| 3-3-0-0 (Biantennary) | 12.45 ± 2.15 | 8.91 ± 1.76 | 0.72 | 0.003 |

| 4-4-0-2 (Disialylated Tetraantennary) | 0.89 ± 0.21 | 2.45 ± 0.67 | 2.75 | <0.0001 |

| 3-4-1-0 (Fucosylated, Galactosylated) | 3.21 ± 0.78 | 6.54 ± 1.23 | 2.04 | 0.001 |

Conclusion: The FGIS approach enables robust, absolute quantification of serum N-glycans. Data confirm significant increases in fucosylated and branched structures in HCC, providing a quantitative foundation for multi-glycan biomarker panels.

Protocol PR-002: Glycoengineered mAb Critical Quality Attribute (CQA) Monitoring via FGIS-MALDI-TOF-MS

Objective: To monitor site-specific glycosylation (e.g., Fc G0, G1, G2, G1F, G2F) on a therapeutic monoclonal antibody (mAb) during bioprocessing using an FGIS workflow for comparability and lot-release analytics.

Detailed Protocol:

Step 1: mAb Digestion and Glycan Release.

- Dilute purified mAb to 1 mg/mL in 50 mM ammonium bicarbonate.

- Add trypsin at a 1:20 (w/w) enzyme-to-substrate ratio. Incubate at 37°C for 4 hours.

- Heat-inactivate at 80°C for 10 min.

- Add PNGase F (2 µL per 100 µg mAb) and incubate at 37°C for 3 hours.

Step 2: FGIS Addition and SPE.

- Spike in 5 µL of mAb-Specific FGIS Mix containing 13C-labeled versions of G0, G1F, G2F, and Man5.

- Acidify sample with 1% TFA.

- Load onto a C18 tip to separate glycans (flow-through) from peptides (retained). Collect flow-through and dry.

Step 3: Permethylation for Enhanced MS Sensitivity.

- Reconstitute dried glycans in DMSO.

- Perform sodium hydroxide/DMSO slurry-based permethylation.

- Extract permethylated glycans with dichloromethane and water. Dry organic phase.

Step 4: MALDI-MS Analysis & Quantification.

- Reconstitute in 10 µL methanol. Spot with DHB matrix.

- Acquire spectra in positive linear mode for higher mass range.

- Use FGIS peaks as internal calibrants and quantification references for each glycoform class.

Table 2: Fc Glycosylation CQA Results for Three Bioreactor Lots of mAb-X

| Glycoform | Lot A (% of Total Glycans) | Lot B (% of Total Glycans) | Lot C (% of Total Glycans) | Specification Target |

|---|---|---|---|---|

| G0F | 2.1 ± 0.3 | 1.9 ± 0.2 | 7.8 ± 0.6 | ≤5.0% |

| G1F | 28.5 ± 1.1 | 30.1 ± 1.3 | 25.4 ± 1.0 | 25-35% |

| G2F | 62.3 ± 1.5 | 60.8 ± 1.7 | 58.9 ± 1.4 | ≥55% |

| Man5 | 0.5 ± 0.1 | 0.4 ± 0.1 | 1.2 ± 0.2 | ≤1.5% |

| Total Afucosylation | 0.8 ± 0.2 | 1.1 ± 0.2 | 1.5 ± 0.3 | ≤2.0% |

Conclusion: FGIS-MALDI-TOF-MS provides a high-throughput, precise method for mAb glycosylation CQA monitoring. Lot C shows a notable excursion in G0F, highlighting the need for process control.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for FGIS-MALDI Glycomics

| Item | Function in Protocol |

|---|---|

| Full Glycome Internal Standard (FGIS) Kit | A predefined mixture of stable isotope (13C)-labeled, non-natural glycans. Serves as internal calibrants and quantification standards for native glycans across the structural range. |

| Recombinant PNGase F (Glycerol-free) | Enzyme for efficient release of N-glycans from glycoproteins under non-denaturing or denaturing conditions. |

| PGC (Porous Graphitized Carbon) SPE Tips | For solid-phase extraction clean-up of released glycans, removing salts and peptides, with selective elution based on hydrophilicity. |

| Super-DHB Matrix | 9:1 mixture of 2,5-dihydroxybenzoic acid and 2-hydroxy-5-methoxybenzoic acid. Optimal matrix for glycan ionization in MALDI-TOF-MS. |

| Permethylation Reagents (DMSO, NaOH, CH3I) | For derivatizing glycans to improve MS ionization efficiency, stabilize sialic acids, and provide structural information via fragmentation. |

| 13C6-Aniline Labeling Reagent | Alternative labeling agent for glycans; 13C-aniline facilitates quantification via mass shift and improved ionization. |

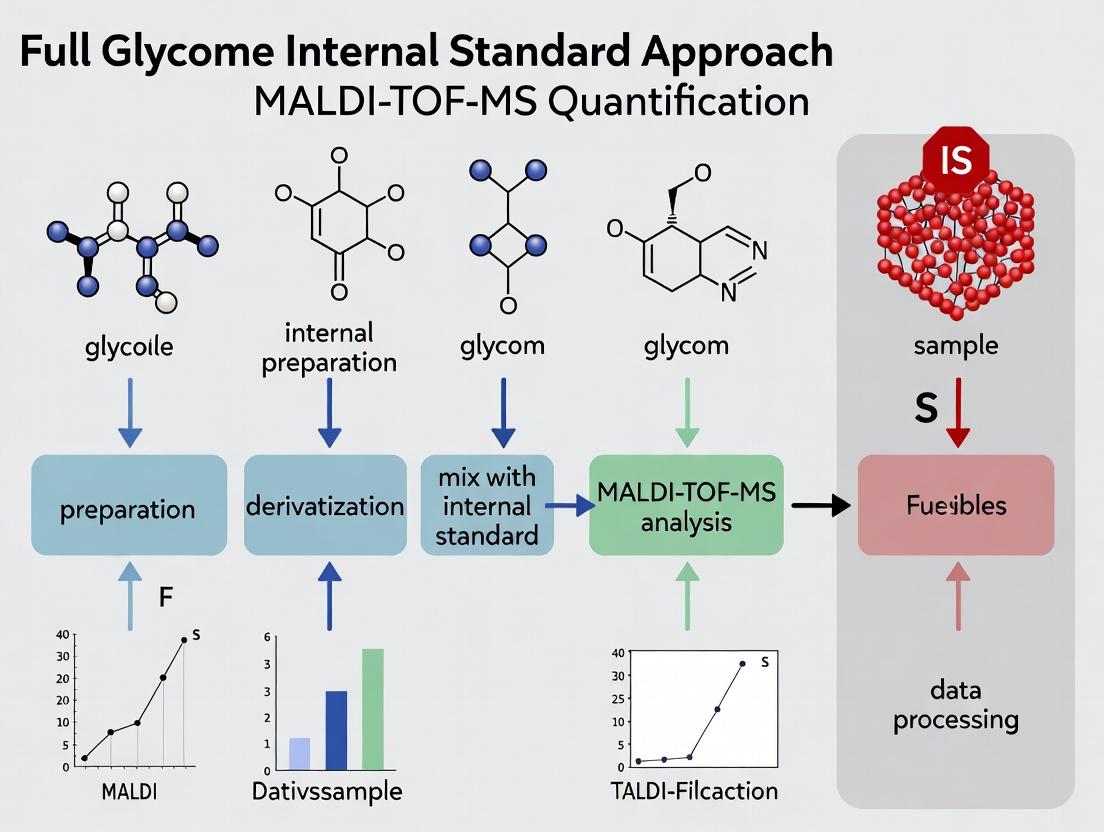

Diagrams

Title: FGIS-MALDI Workflow for Glycan Quantification

Title: Key Enzymes in N-Glycan Biosynthesis Pathway

Application Notes: Quantification Challenges in MALDI-TOF-MS Glycomics

MALDI-TOF-MS is a powerful tool for glycan profiling due to its high sensitivity, speed, and tolerance to salts/buffers. However, its quantitative utility is severely hampered by several inherent factors. The following table summarizes the primary challenges and their quantitative impact based on current literature.

Table 1: Key Quantification Challenges in MALDI-TOF-MS Glycomics

| Challenge | Underlying Cause | Quantitative Impact (Reported Variability) | Proposed Mitigation in Literature |

|---|---|---|---|

| Ion Suppression | Competitive ionization between analytes of different sizes/structures. | Can cause >50% signal variance for co-crystallized analytes. | Extensive sample purification, use of internal standards (IS). |

| Matrix Adduct Formation | Non-covalent binding of matrix ions (e.g., Na+, K+) to glycans. | Multiple peaks per analyte; intensity distribution variable (±15-30%). | Cation exchange resins, controlled salt addition. |

| Laser Shot Heterogeneity | Inhomogeneous co-crystallization of sample and matrix ("sweet spots"). | Spot-to-spot CV often >20-30%; intra-spot CV also high. | Rastering over entire spot, summing many laser shots (≥1000). |

| Differential Desorption/Ionization | Glycans with different masses/structures have different ionization efficiencies. | Response can vary by an order of magnitude for isomeric glycans. | Structuraly matched internal standards (often unavailable). |

| Poor Reproducibility of Matrices | Batch-to-batch variability of common matrices (e.g., DHB). | Inter-day CVs of 25-40% are common without rigorous standardization. | Use of pre-mixed, QC'd commercial matrix solutions. |

The central thesis of employing a "full glycome internal standard" approach seeks to address these challenges by providing a structurally identical, isotopically labeled IS for every native glycan in a sample, thereby normalizing for variability in desorption, ionization, and detection.

Detailed Protocols

Protocol 1: Preparation of Permethylated Glycans for MALDI-TOF-MS Analysis with Spike-In Standards

This protocol is optimized for N-glycan released from glycoproteins or from cell lysates.

Research Reagent Solutions Toolkit:

| Item | Function |

|---|---|

| PNGase F (R-) | Enzyme for releasing N-glycans from glycoproteins/peptides without core α1-3 fucose activity. |

| Anhydrous Dimethyl Sulfoxide (DMSO) | Solvent for the permethylation reaction. |

| Iodomethane (CH₃I) | Methylation reagent for glycan permethylation (enhances sensitivity and stability). |

| Sodium Hydroxide Beads | Solid base catalyst for permethylation. |

| ¹³C-labeled Reducing Agent (e.g., ¹³C-cyanoborohydride) | For generating stable isotope-labeled internal standards via reduction. |

| DHB Matrix Solution (20 mg/mL in 50% ACN, 1 mM NaTFA) | Common MALDI matrix for glycans; DHB = 2,5-Dihydroxybenzoic acid. |

| Cation Exchange Resin (Na+ form) | Converts all glycan adducts to uniform [M+Na]+ ions for simpler spectra. |

| Solid-Phase Extraction (SPE) Cartridges (C18 & Porous Graphitized Carbon) | For purification of released glycans from salts, detergents, and peptides. |

Procedure:

- Glycan Release: Release N-glycans from your target protein (10-100 µg) using PNGase F in a volatile buffer (e.g., 50 mM ammonium bicarbonate, pH 8.0) overnight at 37°C.

- Desalting/Purification: Pass the reaction mixture through a C18 SPE cartridge (to retain peptides/proteins) and collect the flow-through containing glycans. Further purify using a Porous Graphitized Carbon (PGC) SPE cartridge. Elute glycans with 40% acetonitrile (ACN) in 0.1% TFA, then dry completely.

- Spike-In of Isotopic Standards: At this stage, reconstitute the dried native glycans in a known volume of water. Add a predetermined amount of your synthesized full glycome internal standard (FGIS) mixture—a matched set of ¹³C/¹⁵N-labeled glycans.

- Permethylation (Optional but Recommended):

- Prepare a slurry of NaOH beads in anhydrous DMSO.

- Add the glycan sample (with spiked IS) in DMSO to the slurry.

- Add iodomethane dropwise under gentle agitation. React for 15-20 minutes at room temperature.

- Quench the reaction with water.

- Extract permethylated glycans with dichloromethane. Wash the organic layer several times with water and dry.

- Cation Exchange: Reconstitute the permethylated glycans in 20 µL of ACN/water (70:30). Pass through a small column of cation exchange resin (Na+ form) to convert all glycan ions to sodium adducts. Dry the eluent.

- MALDI Target Spotting: Reconstitute the final sample in 10 µL of 50% ACN. Mix 1 µL of this sample with 1 µL of DHB matrix solution on the MALDI target. Allow to dry completely at room temperature.

- Data Acquisition:

- Acquire spectra in positive ion reflection mode.

- Use a laser intensity sufficiently above the threshold to ensure good signal-to-noise.

- Acquire a minimum of 1000 laser shots per spot, rastering across the entire sample spot to average out heterogeneity.

- For quantitative comparison, analyze all samples in a single, randomized run to minimize instrument drift effects.

Protocol 2: Relative Quantification Workflow Using Full Glycome Internal Standards (FGIS)

This protocol outlines the data processing steps after acquisition using the FGIS method.

Procedure:

- Spectral Pre-processing: Perform baseline subtraction, smoothing (Savitzky-Golay), and peak detection (S/N threshold >5) using your instrument software or external tools (e.g., mMass).

- Peak Alignment & Pairing: Align peaks across all spectra in the experiment. For each native (light) glycan peak (m/z = M), identify its corresponding heavy internal standard peak (m/z = M + Δ), where Δ is the known mass shift from isotopic labeling (e.g., 3 Da for a triply charged permethylated glycan reduced with ¹³C-borohydride).

- Peak Intensity Extraction: Extract the integrated peak area (or height) for each light/heavy pair.

- Ratio Calculation & Normalization: Calculate the Light/Heavy (L/H) ratio for each glycan species. Normalize these ratios to a calibrator sample (e.g., a pool of all samples) run on the same target plate to correct for inter-run variability.

- Statistical Analysis: Use the normalized L/H ratios for downstream comparative statistical analysis (e.g., t-tests, ANOVA).

Visualizations

Title: FGIS MALDI-TOF Glycomics Workflow

Title: Quant Hurdles & FGIS Correction Mechanism

The field of clinical glycomics has long relied on relative quantification, reporting glycan changes as normalized percentages or ratios. While informative for discovery, this approach fails to determine the absolute molar quantity of glycans per molecule or per sample volume—a critical parameter for biomarker validation, pharmacokinetic studies, and therapeutic potency assays. This application note positions the development of a Full Glycome Internal Standard (FGIS) approach for MALDI-TOF-MS as a foundational solution to this challenge, enabling the transition from relative profiling to rigorous absolute quantification required for clinical and regulatory decision-making.

The Quantitative Limitation of Relative Glycan Profiling

Relative quantification, typically achieved by normalizing individual glycan peak intensities to total ion count, masks biologically significant changes in absolute abundance. A change in the relative percentage of a glycan can result from an actual increase in its amount or a decrease in other glycans. For regulatory filings, such as for biosimilars or glyco-engineered biologics, absolute concentrations of critical quality attributes (e.g., sialylation, fucosylation) are mandatory.

Table 1: Pitfalls of Relative vs. Requirements of Absolute Quantification

| Aspect | Relative Quantification (Current Standard) | Absolute Quantification (FGIS-Enabled) |

|---|---|---|

| Output | Percentage or fold-change | Picomoles/µL or moles/mole |

| Impact of Total Glycome Shift | Misinterprets changes | Reports true concentration change |

| Cross-Sample Comparison | Challenging; requires equal total input | Directly comparable |

| Longitudinal Study Utility | Limited | High (tracks concentration over time) |

| Regulatory Acceptance | Low for critical attributes | High; required for lot release |

| Biomarker Threshold | Cannot establish concentration cutoff | Enables clinical cutoff definition |

Core Protocol: Absolute Quantification of N-Glycans using a Full Glycome Internal Standard (FGIS) Pool

This protocol details the use of a synthetically generated, quantitated pool of stable isotope-labeled glycans (FGIS) for absolute quantification of native glycans from a therapeutic antibody.

I. Materials & Reagents

- Therapeutic Antibody Sample: 100 µg.

- Full Glycome Internal Standard (FGIS) Pool: A defined molar mixture of ({}^{13})C/({}^{15})N-labeled versions of the expected glycan structures (e.g., G0F, G1F, G2F, Man5, etc.), each quantified by quantitative NMR or amino acid analysis. Store at -80°C.

- PNGase F: Recombinant, glycerol-free.

- Rapid PNGase F Buffer: 5x concentration.

- Reduction & Alkylation Reagents: Dithiothreitol (DTT) and Iodoacetamide (IAM).

- Denaturing Buffer: 1% SDS, 50 mM Tris-HCl, pH 8.0.

- Non-ionic Detergent: 10% Triton X-100 or NP-40.

- Solid-Phase Extraction: Porous graphitized carbon (PGC) tips or columns.

- MALDI Matrix: 2,5-Dihydroxybenzoic acid (DHB) at 10 mg/mL in 50% acetonitrile/0.1% TFA.

- MALDI Target Plate: Polished steel.

II. Step-by-Step Protocol

1. Sample Preparation & Denaturation:

- Take 100 µg of antibody in 50 µL of Denaturing Buffer.

- Heat at 95°C for 5 minutes, then cool to room temperature.

2. Reduction & Alkylation:

- Add DTT to a final concentration of 10 mM. Incubate at 56°C for 30 min.

- Cool, then add IAM to a final concentration of 25 mM. Incubate in the dark at room temperature for 30 min.

3. Enzymatic Release with FGIS Spike-In (Critical Step):

- Add FGIS Pool: Spike a known, precise amount (e.g., 5 pmol total) of the FGIS into the alkylated antibody sample. This step is the cornerstone of absolute quantification.

- Add Non-ionic Detergent: Add 10% Triton X-100 to a final concentration of 2% to sequester SDS.

- Add Buffer & Enzyme: Add Rapid PNGase F Buffer and 2 µL (1000 units) of PNGase F.

- Incubate: Incubate at 50°C for 30 minutes.

4. Glycan Cleanup (PGC Solid-Phase Extraction):

- Condition PGC tip with 80% acetonitrile/0.1% TFA, then equilibrate with 0.1% TFA.

- Load the glycan release mixture (native + FGIS) onto the tip.

- Wash with 0.1% TFA to remove salts and detergents.

- Elute glycans with 40% acetonitrile/0.1% TFA, followed by 60% acetonitrile/0.1% TFA. Combine eluents and dry in a vacuum concentrator.

5. MALDI-TOF-MS Spotting and Acquisition:

- Reconstitute dried glycans in 10 µL of ultrapure water.

- Mix 1 µL of glycan solution with 1 µL of DHB matrix on the MALDI target. Allow to crystallize.

- Acquire spectra in positive ion reflection mode. Acquire a minimum of 2000 laser shots per spot from random positions.

III. Data Analysis & Calculation For each glycan pair (native light, isotopic heavy):

- Identify the light (L) and heavy (H) peak pair (mass difference depends on labeling strategy, e.g., ({}^{13}C_{6}) for Hexose).

- Integrate the peak areas for both the native (AL) and its corresponding FGIS standard (AH).

- The absolute amount of the native glycan is calculated using the known amount of the spiked FGIS standard:

- Normalize to sample input to report pmol/µg of antibody or glycan moles/mole of protein.

Table 2: Example Calculation for a Monoclonal Antibody

| Glycan Structure | Native m/z [M+Na]+ | FGIS m/z [M+Na]+ | FGIS Spiked (pmol) | A_L (Intensity) | A_H (Intensity) | Calculated Absolute Amount (pmol) | Glycan Occupancy (moles/mol mAb) |

|---|---|---|---|---|---|---|---|

| G0F | 1479.5 | 1485.5 | 0.50 | 15,000 | 10,000 | 0.75 | 1.5 |

| G1F | 1641.6 | 1647.6 | 0.50 | 25,000 | 10,000 | 1.25 | 2.5 |

| Man5 | 1255.4 | 1261.4 | 0.25 | 2,500 | 5,000 | 0.125 | 0.25 |

The Scientist's Toolkit: Essential Reagent Solutions

| Item | Function in FGIS Quantification |

|---|---|

| Full Glycome Internal Standard (FGIS) Pool | A pre-quantitated, isotope-labeled library of glycans. Serves as the primary calibrant for every target structure, correcting for ionization bias and recovery losses. |

| Glycerol-free PNGase F | Efficiently releases N-glycans without introducing polymeric glycerol adducts that interfere with the MS spectrum, especially in the low-mass region. |

| Porous Graphitized Carbon (PGC) Tips | Provides robust, selective cleanup of released glycans, removing salts, detergents, and peptides that suppress ionization in MALDI. |

| Quantitative NMR Reference | The independent analytical method used to certify the absolute concentration of each component in the FGIS primary stock, ensuring traceability. |

| ({}^{13}C/^{15})N-labeled Monosaccharides | The metabolic or synthetic building blocks used to create the isotopically heavy, chemically identical FGIS glycans. |

Visualization of Concepts and Workflows

Title: Quantitative Paradigms and Their Applications

Title: FGIS-Based Absolute Quantification Workflow

Title: Core Absolute Quantification Formula

Core Concept Definition

A "Full Glycome" Internal Standard (FGIS) is a synthetically generated, isotopically labeled glycan library designed to comprehensively mirror the structural diversity and quantitative abundance of glycans present in a biological sample. It serves as a universal internal reference for the absolute quantification of glycans via mass spectrometry (MS), particularly Matrix-Assisted Laser Desorption/Ionization Time-of-Flight (MALDI-TOF-MS). Unlike traditional single-isotope internal standards that target specific glycans, an FGIS aims to cover the entire theoretical glycome space—encompassing N-linked, O-linked, and glycosphingolipid-derived glycans across a defined mass range—with each standard bearing a uniform heavy isotope tag (e.g., ( ^{13}C ), ( ^{15}N )) for distinguishable MS signals.

Application Notes

Primary Application: Absolute Quantification in Biomarker Discovery & Biopharmaceutical Development.

- Use Case: In the development of monoclonal antibodies (mAbs), the glycosylation profile critically influences efficacy, stability, and immunogenicity. An FGIS enables parallel, absolute quantification of all major glycoforms (e.g., G0F, G1F, G2F, Man5) in a single MALDI-TOF-MS run, providing a precise glycosylation footprint for critical quality attribute (CQA) assessment.

- Advantage over Traditional Methods: Replaces the need for multiple, individually synthesized labeled standards, reducing cost, experimental complexity, and potential for quantification bias. It corrects for ion suppression effects and matrix crystallization variability inherent to MALDI-MS.

Secondary Application: Inter-Laboratory Method Standardization.

- Use Case: Multi-site studies in glycomics require reproducible data. An FGIS kit provides a common reference point across instruments and platforms, allowing for direct comparison of glycan abundance data from different laboratories, essential for clinical research and drug regulatory submissions.

Experimental Protocol: Absolute Quantification of Serum N-Glycome Using FGIS

Objective: To absolutely quantify the major N-glycan species in human serum using a compatible FGIS.

Materials & Reagents:

- Human serum sample.

- "Full Glycome" Internal Standard Kit (e.g., hypothetical "GlycoQuant Full-Glycan ( ^{13}C )-IS Mix").

- PNGase F enzyme (for N-glycan release).

- Solid-phase extraction (SPE) cartridges for glycan purification (e.g., graphitized carbon).

- MALDI matrix: 2,5-Dihydroxybenzoic acid (DHB) or α-Cyano-4-hydroxycinnamic acid (CHCA).

- MALDI target plate.

- MALDI-TOF/TOF mass spectrometer.

Detailed Protocol:

Step 1: Sample Preparation & Glycan Release

- Deplete high-abundance proteins from 10 µL of serum using an albumin/IgG removal column.

- Denature the depleted proteins with 1% SDS and 10mM DTT at 60°C for 30 min.

- Release N-glycans by incubating with 2 µL PNGase F (5 U/µL) in 50mM ammonium bicarbonate buffer (pH 7.8) for 18 hours at 37°C.

Step 2: Co-Processing with FGIS

- Critical Step: At the beginning of the release step (Step 1.3), add a precise volume (e.g., 5 µL) of the FGIS solution. This ensures the labeled standards undergo identical processing, purification, and analysis as the native glycans, correcting for all procedural losses.

- Terminate the reaction by heating at 80°C for 10 min.

Step 3: Glycan Cleanup

- Purify the released glycans (both native and FGIS) using a graphitized carbon solid-phase extraction (SPE) cartridge.

- Condition cartridge with 5 mL ACN and 5 mL H₂O.

- Load sample, wash with 10 mL H₂O to remove salts.

- Elute glycans with 2 mL of 30% ACN containing 0.1% TFA.

- Lyophilize the eluent to dryness.

Step 4: MALDI-TOF-MS Analysis

- Reconstitute dried glycans in 20 µL ultra-pure water.

- Spot 1 µL of glycan solution mixed 1:1 with DHB matrix solution (20 mg/mL in 50% ACN) on the MALDI target. Allow to crystallize.

- Acquire mass spectra in positive ion reflection mode. Accumulate at least 2000 laser shots per spot.

- Key Instrument Settings: Mass range: m/z 1000-3500; Laser intensity: just above threshold; Pulsed ion extraction optimized for glycan detection.

Step 5: Data Analysis & Quantification

- Identify pairs of peaks for each glycan structure: a light peak (native) and a corresponding heavy peak (FGIS, shifted by a known mass delta, e.g., +6 Da per ( ^{13}C_6 ) label).

- Integrate the area under the peak (AUC) for both light (AUC(L)) and heavy (AUC(H)) signals.

- Calculate absolute amount using the known amount of each glycan in the spiked FGIS.

- Formula: [ \text{Absolute Amount (pmol)} = \frac{AUCL}{AUCH} \times \text{Amount of FGIS Glycan Spiked (pmol)} ]

- Normalize data to total protein concentration or total glycan signal as required.

Table 1: Theoretical Coverage of a Model FGIS for Human Serum N-Glycome Analysis

| Glycan Class | Key Representative Structures (Composition) | Theoretical m/z [M+Na]⁺ | FGIS m/z [M+Na]⁺ (with ( ^{13}C_6 )) | Expected Abundance Range in Normal Serum (Relative %) |

|---|---|---|---|---|

| High Mannose | Man5 | 1257.4 | 1263.4 | 1-3% |

| Hybrid | HexNAc(4)Hex(5) | 1663.6 | 1669.6 | 2-5% |

| Complex (Neutral) | HexNAc(4)Hex(5)Fuc(1) (A2G0F) | 1809.6 | 1815.6 | 10-20% |

| Complex (Neutral) | HexNAc(5)Hex(6)Fuc(1) (A2G1F) | 2012.7 | 2018.7 | 15-25% |

| Complex (Sialylated) | HexNAc(4)Hex(5)Neu5Ac(1) | 1882.6 | 1888.6 | 5-10% |

| Complex (Sialylated) | HexNAc(5)Hex(6)Neu5Ac(2) | 2243.8 | 2249.8 | 8-15% |

Table 2: Comparison of Quantification Approaches in Glycomics

| Parameter | External Standard Calibration | Single-Point Internal Standard (IS) | "Full Glycome" Internal Standard (FGIS) |

|---|---|---|---|

| Accuracy | Low (Susceptible to matrix effects) | Medium (Corrects for some losses) | High (Corrects for all process losses) |

| Precision (% RSD) | >20% | 10-15% | <10% |

| Glycan Coverage | Unlimited but non-parallel | Single target | Comprehensive & Parallel |

| Throughput | Low (Multiple runs) | Medium | High (Single run) |

| Cost per Analysis | Low | High (for multiple glycans) | Medium (High initial investment) |

Visualization of the FGIS Workflow and Quantification Logic

Diagram 1 Title: FGIS Workflow for Glycan Quantification

Diagram 2 Title: FGIS Correction Logic for Quantification Errors

The Scientist's Toolkit: Essential Reagents & Materials

Table 3: Key Research Reagent Solutions for FGIS-based Glycomics

| Item Name | Function & Role in Experiment | Example Vendor/Product (Hypothetical) |

|---|---|---|

| Full Glycome IS Kit | Pre-mixed, quantified library of isotope-labeled glycans. Serves as the universal internal standard for absolute quantification. | "GlycoQuant Pro FGIS Kit" |

| High-Purity PNGase F | Enzyme for efficient, non-reductive release of N-glycans from glycoproteins. Critical for sample preparation. | Promega PNGase F (Glycerol-free) |

| Graphitized Carbon SPE Cartridges | For purification and desalting of released glycans prior to MS. Removes peptides, salts, and detergents. | Thermo Scientific HyperSep Carbon |

| DHB Matrix Solution | MALDI matrix optimized for glycan analysis. Promotes ionization with minimal fragmentation. | Sigma-Aldrich DHB, Super-DHB |

| Stable Isotope Labeled Sialic Acid | For metabolic labeling or derivatization studies in cell-based systems, complementing the FGIS approach. | Omicron Biochemicals ( ^{13}C_6 )-Neu5Ac |

| Glycan Labeling Reagent | (Optional) For derivatization (e.g., Girard's T) to enhance ionization or enable LC separation before MALDI-MS. | Procainamide Labeling Kit (Ludger) |

Within the thesis framework of a Full glycome internal standard approach for MALDI-TOF-MS quantification, selecting the appropriate internal standard (IS) is a foundational decision. Accurate quantification of glycans, crucial for biomarker discovery and biotherapeutic development, hinges on the IS's ability to correct for analyte losses and ionization variability during matrix-assisted laser desorption/ionization time-of-flight mass spectrometry (MALDI-TOF-MS) analysis. This Application Note details the critical comparison between isotope-labeled and structural analog standards, providing protocols and data to guide researchers in choosing the right basis for their glycomic quantification.

Core Comparison and Quantitative Data

Table 1: Comparative Analysis of Internal Standard Types for Glycan Quantification via MALDI-TOF-MS

| Characteristic | Isotope-Labeled Standard (e.g., ¹³C, ²H, ¹⁵N) | Structural Analog Standard (e.g., Deoxy, Deuterated alkylation) |

|---|---|---|

| Chemical Identity | Virtually identical to native analyte. | Structurally similar, but with a deliberate minor modification. |

| Chromatographic Co-elution | Excellent. Exhibits identical retention in LC-MALDI setups. | May show slight deviation, leading to potential separation. |

| Ionization Efficiency | Matches the native analyte precisely. | Can differ, leading to quantification bias. |

| Mass Spectrometric Resolution | Requires high-resolution MS for separation from native peak. | Easily resolved in low-resolution MS (e.g., MALDI-TOF). |

| Cost & Synthetic Complexity | High cost; complex chemical/enzymatic synthesis. | Generally lower cost; simpler chemical synthesis. |

| Availability for Glycans | Limited commercial availability; often requires custom synthesis. | Broader availability (e.g., 2-AA labeled dextran ladders, modified glycans). |

| Primary Correction Function | Compensates for ionization variance and sample preparation losses. | Primarily corrects for sample preparation losses. |

| Best For | Absolute quantification; high-precision workflows where cost is secondary. | Relative quantification; high-throughput screening; limited budget projects. |

Table 2: Example Quantitative Performance Data in a Glycan Profiling Experiment

| Glycan Analyte | IS Type | Spiked Amount (pmol) | Measured Amount (Mean ± RSD, n=6) | Accuracy (%) | Precision (RSD%) |

|---|---|---|---|---|---|

| A2G2S2 | ¹³C₆-2-AA Labeled A2G2S2 | 10.0 | 10.2 ± 3.1% | 102 | 3.1 |

| A2G2S2 | Structural Analog (Deoxy) | 10.0 | 9.5 ± 6.8% | 95 | 6.8 |

| FA2G2 | ¹³C₆-2-AA Labeled FA2G2 | 5.0 | 4.9 ± 4.0% | 98 | 4.0 |

| FA2G2 | Structural Analog (Deoxy) | 5.0 | 5.3 ± 8.2% | 106 | 8.2 |

| M5 | Deuterated PMP-Labeled M5 | 20.0 | 19.7 ± 5.5% | 98.5 | 5.5 |

Experimental Protocols

Protocol 1: Absolute Quantification of N-Glycans Using ¹³C-Labeled Internal Standards

Objective: To absolutely quantify released serum N-glycans using a full set of ¹³C-labeled IS.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Sample Preparation: Denature 10 µL of serum (or glycoprotein) with 25 µL of 1% SDS and 10 mM DTT at 60°C for 30 min.

- Release: Add 10 µL of 10% NP-40 and 2.5 µL (250 U) of PNGase F. Incubate at 37°C for 18 hours.

- Internal Standard Addition: Spike a known amount (e.g., 5 pmol) of each ¹³C₆-2-AA labeled N-glycan standard (covering the expected glycan classes) into the released glycan sample.

- Cleanup: Purify glycans using solid-phase extraction (SPE) with porous graphitized carbon (PGC) cartridges.

- Condition with 3 mL 80% ACN/0.1% TFA.

- Equilibrate with 3 mL 0.1% TFA.

- Load sample.

- Wash with 3 mL 0.1% TFA.

- Elute glycans with 1 mL 40% ACN/0.1% TFA, followed by 1 mL 80% ACN/0.1% TFA. Dry eluents.

- MALDI Target Spotting: Reconstitute in 10 µL water. Mix 1 µL sample with 1 µL of 10 mg/mL DHB matrix (in 50% ACN, 1 mM NaCl) on the target. Allow to dry.

- MS Acquisition: Acquire spectra in positive reflector mode (m/z 1000-5000). Use a laser intensity 10-20% above threshold. Accumulate 2000 shots per spot.

- Data Analysis: Integrate peak areas for native ([M+Na]+) and isotopically shifted IS ([M+6+Na]+) pairs. Calculate concentration using the known IS amount and the area ratio.

Protocol 2: Relative Quantification Using Structural Analog Dextran Ladder Standards

Objective: To profile and relatively quantify O-glycans using a commercial dextran ladder as a structural analog IS.

Procedure:

- Release & Labeling: Release O-glycans from glycoprotein via reductive β-elimination. Co-label the released sample and a dextran ladder (hydrolyzed glucose polymers) with 2-AA or PMP fluorophore/tag.

- Internal Standard Spiking: Spike a fixed amount of the labeled dextran ladder into the labeled sample glycan mixture.

- Cleanup: Remove excess label using HILIC-SPE or chloroform liquid-liquid extraction.

- MALDI Target Spotting: Spot as in Protocol 1.

- MS Acquisition: Acquire spectra in linear positive ion mode for broader mass range.

- Data Analysis: Use the known molar amount of each dextran oligomer (e.g., DP6, DP7, etc.) to create a response factor curve across the m/z range. Normalize sample glycan signals to the nearest dextran standard to account for preparation losses and generate relative abundances.

Visualizations

Decision Workflow for Internal Standard Selection

Quantification Workflows for Two IS Types

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Glycan Quantification

| Item | Function & Role in Quantification |

|---|---|

| PNGase F (or R) | Enzyme for releasing N-glycans from glycoproteins. Critical for consistent, complete liberation of analytes. |

| ¹³C₆-Aniline (2-AA) | Isotope-labeled tag for glycan derivatization. Provides +6 Da mass shift, enabling precise MS pair detection. |

| Porous Graphitized Carbon (PGC) | SPE cartridges for glycan purification. Removes salts, detergents, and peptides post-release. |

| Deuterated PMP (d5-PMP) | Structural analog labeling reagent. Introduces a fixed +5 Da shift vs. native PMP, easy for TOF resolution. |

| 2-AA Labeled Dextran Ladder | Structural analog internal standard mix. Provides a series of calibrants across a wide m/z range. |

| DHB Matrix with NaCl | MALDI matrix for glycans. Promotes [M+Na]+ adduct formation for consistent, sensitive ionization. |

| Sialidase Mix (e.g., SialEXO) | Enzyme for removing sialic acids. Can simplify spectra by converting complex glycans to asialo-forms. |

Step-by-Step Protocol: Implementing a Full Glycome IS Strategy for Robust MALDI-TOF-MS Quantitation

Application Notes

In the pursuit of absolute quantification of glycans via MALDI-TOF-MS as part of a full glycome internal standard approach, the selection of the internal standard (IS) is paramount. The choice between uniform (same chemical structure) and stable isotope-labeled (e.g., (^{13})C/(^{15})N) glycans presents a strategic dilemma with significant implications for data accuracy, cost, and workflow feasibility.

Uniform Glycan IS: A structurally identical, but exogenously added, glycan. Its limitation is the potential for contribution to the endogenous signal if not chromatographically or spatially resolved, leading to inaccurate quantification.

(^{13})C/(^{15})N-Labeled Glycan IS: A glycan where atoms are replaced with heavy stable isotopes. It is chemically and physicochemically identical to the native analyte but exhibits a predictable mass shift, allowing for co-elution/separation in MS and unambiguous distinction from the endogenous signal. This is the gold standard for precise quantification.

Critical Consideration - Source: The core challenge for a full glycome approach is sourcing a comprehensive library of labeled glycans. While uniform glycans are commercially available for many structures, the availability of site-specifically (^{13})C/(^{15})N-labeled glycans is extremely limited and prohibitively expensive for large-scale glycome profiling. Strategic sourcing often involves custom chemical or chemoenzymatic synthesis.

Quantitative Data Comparison:

Table 1: Comparative Analysis of Internal Standard Types for Glycan MALDI-TOF-MS Quantification

| Feature | Uniform Glycan IS | (^{13})C/(^{15})N-Labeled Glycan IS |

|---|---|---|

| Chemical Identity | Identical | Identical |

| Mass Difference | None (co-detection) | +2 to +10 Da per label (shifted detection) |

| Chromatography Required | Mandatory for resolution | Beneficial but not mandatory |

| Risk of Signal Interference | High (from endogenous analyte) | Negligible |

| Quantification Accuracy | Moderate to Low | High |

| Commercial Availability | Broad for common structures | Very limited, custom synthesis dominant |

| Relative Cost per Standard | Low to Moderate | Very High |

| Suitability for Full Glycome | Logistically feasible, analytically compromised | Analytically ideal, logistically challenging |

Table 2: Performance Metrics in a Model N-Glycan Quantification Experiment (Hypothetical Data)

| Metric | Uniform 2-AB-labeled IS | (^{13}C_6)-2-AB-labeled IS |

|---|---|---|

| Linear Dynamic Range | 2 orders of magnitude | 4 orders of magnitude |

| Limit of Quantification (LOQ) | 500 fmol | 50 fmol |

| Accuracy at Mid-range (%) | 85% ± 15 | 99% ± 5 |

| Intra-day Precision (%CV) | 12% | 3% |

| Impact of Incomplete Chromatography | Severe (signal merging) | Minimal |

Experimental Protocols

Protocol 1: Quantification Using a Uniform Glycan Internal Standard with LC-MALDI-TOF-MS

Objective: To quantify a specific N-glycan (e.g., A2G2S2) in a biological sample using a uniform IS, relying on chromatographic separation prior to MS spotting.

Materials: See "The Scientist's Toolkit" below. Procedure:

- Sample Preparation: Release N-glycans from glycoproteins in the sample and standard using PNGase F. Purify via solid-phase extraction (SPE).

- Derivatization: Label purified glycans from both sample and IS stock with 2-aminobenzamide (2-AB) via reductive amination. Quench the reaction and remove excess dye.

- Spiking: Add a known amount (e.g., 50 pmol) of uniform A2G2S2-2AB IS to the labeled sample glycan pool.

- Chromatographic Separation:

- Perform hydrophilic interaction liquid chromatography (HILIC) with fluorescence detection.

- Precisely collect the fraction corresponding to the retention time of the A2G2S2 glycan, as determined by an external standard ladder.

- MALDI Target Spotting:

- Mix the collected HILIC fraction 1:1 (v/v) with DHB matrix solution (20 mg/mL in 50% ACN, 1 mM NaOH).

- Spot 1 µL onto the MALDI target plate and allow to dry.

- MS Acquisition & Data Analysis:

- Acquire spectra in positive ion, reflection mode.

- Identify the peak for [A2G2S2-2AB+Na]+ from both the endogenous glycan and the IS (they will be at the same m/z).

- Crucial: Integrate the peak area only from the chromatographically resolved IS spike. Use this IS area to construct a calibration curve from separate calibration runs with known amounts of uniform standard.

- Quantify the endogenous glycan by comparing its peak area to the calibration curve, correcting for the IS recovery.

Protocol 2: Quantification Using a (^{13})C/(^{15})N-Labeled Glycan Internal Standard with Direct MALDI-TOF-MS

Objective: To quantify a specific N-glycan using a stable isotope-labeled IS, enabling direct mixture analysis without prior chromatographic separation.

Materials: See "The Scientist's Toolkit" below. Procedure:

- Parallel Processing: Process the biological sample and a known amount of the (^{13}C_6)-2-AB-labeled A2G2S2 IS separately through release (PNGase F) and purification. Note: The labeled IS can be added post-purification if its purity is certified.

- Derivatization (if IS is not pre-labeled): Label the sample glycans with standard 2-AB. The IS is already stably labeled.

- Spiking & Mixing: Combine a known aliquot of the processed sample glycan pool with a precise amount (e.g., 50 pmol) of the (^{13}C_6)-2-AB-labeled A2G2S2 IS.

- MALDI Target Spotting:

- Mix the combined glycan/IS mixture 1:1 with DHB matrix.

- Spot 1 µL onto the target.

- MS Acquisition:

- Acquire spectra as in Protocol 1.

- Identify the doublet peaks: [A2G2S2+2-AB+Na]+ (native, m/z M) and [A2G2S2+(^{13}C_6)-2-AB+Na]+ (IS, m/z M+6).

- Data Analysis:

- Integrate the peak areas for both the native (Anative) and IS (AIS) signals.

- Calculate the amount of endogenous glycan using the known amount of spiked IS:

[Native] = (A_native / A_IS) * [IS_spiked]. - Use a calibration curve from mixtures of known native:IS ratios to account for any potential isotopic effects on ionization efficiency.

Mandatory Visualization

Internal Standard Selection and Analytical Workflow

Conceptual Comparison of Signal Detection

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Glycan Internal Standard Quantification

| Item | Function/Benefit | Example/Specification |

|---|---|---|

| PNGase F | Enzyme for releasing N-linked glycans from glycoproteins. Essential for sample and standard preparation. | Recombinant, glycerol-free, 500,000 U/mL. |

| 2-Aminobenzamide (2-AB) | Fluorescent tag for derivatization. Enables HILIC-FD detection and improves MS ionization. | ≥98% purity, in kit with reducing agent (NaBH3CN). |

| (^{13}C_6)-2-Aminobenzamide | Stable isotope-labeled derivative. Allows synthesis of mass-shifted glycan IS without structural change. | Custom synthesis, 99 atom % (^{13}C). |

| HILIC Column | For chromatographic separation of isobaric/uniform glycan/IS mixtures. | e.g., BEH Amide, 1.7 µm, 2.1 x 150 mm. |

| DHB Matrix | MALDI matrix for glycan analysis. Promotes [M+Na]+ ion formation with low fragmentation. | 2,5-Dihydroxybenzoic acid, ≥99.9% (HPLC). |

| Solid-Phase Extraction (SPE) Plates | For rapid purification and desalting of released glycans post-enzymatic digestion and labeling. | Porous graphitized carbon (PGC) or hydrophilic-modified. |

| Commercial Uniform Glycan Library | Source of well-characterized uniform IS for method development or partial glycome panels. | e.g., 2-AB-labeled N-glycan library, 50+ structures. |

| Custom (^{13}C/(^{15})N) Synthesis Service | Strategic sourcing for labeled glycans not commercially available. Critical for full glycome approach. | Contract with specialized carbohydrate synthesis labs. |

1. Introduction Within the context of developing a Full Glycome Internal Standard (FGIS) approach for absolute quantification via MALDI-TOF-MS, sample preparation is the critical foundation. This protocol details an integrated workflow for glycoprotein/glycan analysis where isotopically labeled internal standards (IS) are introduced at the initial lysis or release step. This early integration corrects for losses and variability throughout the entire purification and processing pipeline, ensuring robust quantitative data for glycomic and glycoproteomic research in drug development.

2. Key Research Reagent Solutions

| Reagent/Material | Function in FGIS Workflow |

|---|---|

Stable Isotope-Labeled Cell Culture Media (e.g., SILAC, 13C6-Lys/Arg) |

Cultivates cells to produce fully isotopically labeled glycoprotein standards, serving as the source for the FGIS spike. |

| Lysis Buffer with Protease/Glycosidase Inhibitors (e.g., RIPA with PMSF, EDTA) | Ensures complete and reproducible cellular lysis or tissue homogenization while preserving native glycan structures from enzymatic degradation. |

Chemical Release Agents (e.g., anhydrous hydrazine, 13C-labeled aniline) |

Directly releases N- and O-glycans from glycoproteins. Isotopically labeled agents allow for immediate IS generation during release. |

| Immobilized Enzyme Beads (e.g., PNGase F agarose, Trypsin resin) | Enables efficient, on-bead simultaneous digestion (e.g., proteolysis and deglycosylation) and easy purification, minimizing sample loss. |

| Solid-Phase Extraction (SPE) Microplates (e.g., PGC, HILIC, C18) | Provides high-throughput, reproducible purification and desalting of released glycans or glycopeptides prior to MALDI-TOF-MS spotting. |

Derivatization Reagents (e.g., 12C/13C-plexed Girard's P reagent) |

Labels reducing ends of glycans with stable isotopes, creating isobaric or mass-shifted pairs for precise relative quantification. |

3. Integrated Experimental Protocol: From Lysis to Purified Glycans

3.1. Principle An isotopically labeled FGIS sample (e.g., from heavy SILAC cells) is mixed with the experimental biological sample at the point of cell lysis or direct glycan release. The two pools co-process through all subsequent steps—digestion, release, and purification—ensuring identical handling. The final MALDI-TOF-MS analysis distinguishes analyte and IS by mass shift, enabling absolute quantification.

3.2. Detailed Protocol A: Integrated Workflow for N-Glycan Profiling

Step 1: Early Internal Standard Integration & Lysis

- Harvest target cells/tissue (light, experimental sample).

- Weigh/Count cells. For every 1x10^6 cells or 10 mg tissue, add a precisely measured aliquot (e.g., 10 µg total protein equivalent) of the FGIS spike (lysate from heavy SILAC-cultured equivalent cells).

- Immediately co-lyse the combined sample in 200 µL of ice-cold Lysis Buffer (50 mM Tris-HCl, pH 7.5, 150 mM NaCl, 1% NP-40, 0.5% sodium deoxycholate, supplemented with 1x protease/phosphatase inhibitor cocktail and 1 mM PMSF).

- Sonicate on ice (3 pulses of 10 sec each, 30% amplitude). Centrifuge at 16,000 x g for 15 min at 4°C. Transfer supernatant (total protein lysate) to a clean tube.

Step 2: On-Bead Denaturation, Reduction, Alkylation, and Digestion

- Quantify total protein concentration using a Bradford assay. Use 50 µg of total combined protein for processing.

- Bind protein to 20 µL of washed C18 or hydrophilic magnetic beads by incubation in 80% acetonitrile (ACN) for 5 min.

- On-bead processing: Sequentially incubate beads with:

- Denaturation/Reduction: 50 µL of 50 mM ammonium bicarbonate (ABC) with 0.1% RapiGest and 10 mM DTT, 10 min at 60°C.

- Alkylation: 50 µL of 50 mM ABC with 25 mM iodoacetamide, 20 min at RT in the dark.

- Quenching: Add 5 µL of 50 mM DTT.

- Trypsin Digestion: Resuspend beads in 50 µL of 50 mM ABC with 1 µg of sequencing-grade trypsin. Incubate overnight at 37°C with shaking.

- On-bead Deglycosylation: Without eluting peptides, adjust buffer conditions by adding 50 µL of 50 mM ABC. Add 2 µL (1000 units) of PNGase F (recombinant, glycerol-free). Incubate for 4 hours at 37°C with shaking. (Released glycans are now in the supernatant; peptides remain bead-bound).

Step 3: Co-Purification of Released N-Glycans

- Magnetically separate beads, carefully transfer the supernatant (containing released glycans from both light and heavy IS pools) to a new tube.

- Acidity supernatant with 1% trifluoroacetic acid (TFA) to degrade RapiGest and stop enzymes. Centrifuge to remove precipitate.

- Load supernatant onto a graphitized carbon (PGC) solid-phase extraction tip.

- Wash with 10 column volumes of 0.1% TFA in water.

- Elute glycans with 30% ACN in 0.1% TFA, followed by 50% ACN in 0.1% TFA. Combine eluates and dry in a vacuum concentrator.

Step 4: MALDI Target Preparation

- Reconstitute dried glycans in 10 µL of ultrapure water.

- Mix 1 µL of glycan solution with 1 µL of DHB matrix (20 mg/mL in 70% ACN) on a MALDI target plate.

- Allow to crystallize at room temperature.

- Acquire spectra in positive ion reflector mode on a MALDI-TOF/TOF instrument.

3.3. Data Analysis & Quantification Table Quantification is achieved by comparing the peak intensities or areas of the light (analyte) and heavy (IS) forms of each glycan composition. Representative simulated data:

| Glycan Composition (HexNAc+Hex+Fuc+NeuAc) | m/z (Light, [M+Na]⁺) | m/z (Heavy IS, [M+Na]⁺) | Light Peak Area | Heavy IS Peak Area | Ratio (Light/Heavy) | Calculated Amount (pmol)* |

|---|---|---|---|---|---|---|

| H5N4F1 | 1901.685 | 1910.725 | 12500 | 12000 | 1.04 | 10.4 |

| H5N4S1 | 1832.648 | 1841.688 | 9800 | 10500 | 0.93 | 9.3 |

| H3N5F1S2 | 2247.782 | 2265.862 | 4500 | 5000 | 0.90 | 9.0 |

*Assuming 10 pmol of each heavy IS glycan was spiked.

4. Visualized Workflows

Title: Integrated FGIS Workflow from Sample to Data

Title: On-Bead Integrated Digestion & Release Protocol

Context: This work supports a thesis on a "Full glycome internal standard approach for MALDI-TOF-MS quantification" by establishing the foundational, glycan-class-specific analytical methods required for robust and reproducible spectral acquisition.

Matrix selection is critical for effective glycan analysis via MALDI-TOF-MS, significantly impacting sensitivity, signal-to-noise ratio (S/N), and the extent of in-source/post-source decay. Within the framework of quantitative full glycome analysis using universal isotopic or isobaric internal standards, consistent and optimal matrix performance for each glycan class is non-negotiable. This protocol compares three widely used matrices—2,5-Dihydroxybenzoic acid (DHB), 2',4',6'-Trihydroxyacetophenone (THAP), and Super-DHB (a 9:1 mixture of DHB and 2-Hydroxy-5-methoxybenzoic acid)—for the analysis of N-glycans, O-glycans, and glycosaminoglycans (GAGs).

Table 1: Matrix Performance Characteristics by Glycan Class

| Glycan Class | Recommended Matrix | Key Advantages | Key Limitations | Typical m/z Range (Optimal) |

|---|---|---|---|---|

| N-Glycans (Neutral, Sialylated) | Super-DHB | Superior crystallization, enhanced sensitivity for higher m/z, reduced peak tailing. Good for sialylated glycans. | Slightly more preparation time. | 1000 – 5000 |

| DHB | Robust, reliable; good for broad profiling. Classic "sweet spot" technique. | "Hot" matrix; can promote desialylation. Heterogeneous crystals. | 1000 – 5000 | |

| O-Glycans (Mucin-type) | THAP | "Cool" matrix; minimal fragmentation, preserves labile sulfate/sialic acid. | Lower sensitivity for >2500 m/z. | 500 – 2500 |

| Super-DHB | Good alternative for neutral O-glycan cores. | May cause some in-source decay of sialylated forms. | 500 – 2500 | |

| GAGs (HS, CS/DS) | THAP | Essential for sulfated glycans; minimizes loss of labile sulfate groups. | Very low mass cutoff required for analysis. | 500 – 4000 |

| Free Oligosaccharides & Glycolipid Glycans | DHB / Super-DHB | Good sensitivity for neutral species. | 500 – 2500 |

Table 2: Quantitative Comparison of Signal-to-Noise (S/N) for a Standard N-Glycan Man5

| Matrix | Conc. (mg/mL) | Solvent | Avg. S/N (n=5) | %RSD (Peak Intensity) | Crystallization Homogeneity |

|---|---|---|---|---|---|

| DHB | 20 | 50% ACN, 0.1% TFA | 125 | 15% | Low/Moderate |

| Super-DHB | 20 | 50% ACN, 0.1% TFA | 210 | 8% | High |

| THAP | 50 | 100% Ethanol | 45 | 20% | High |

Detailed Experimental Protocols

Protocol 1: Preparation of Matrix Solutions

- DHB: Dissolve 20 mg of DHB in 1 mL of 50% Acetonitrile (ACN) / 0.1% Trifluoroacetic Acid (TFA) in water. Vortex and sonicate until fully dissolved.

- Super-DHB: Weigh 18 mg of DHB and 2 mg of 2-Hydroxy-5-methoxybenzoic acid. Dissolve in 1 mL of 50% ACN / 0.1% TFA. Vortex and sonicate.

- THAP: Dissolve 50 mg of THAP in 1 mL of 100% ethanol or 100% ACN. Vortex thoroughly.

Protocol 2: Glycan Sample Preparation & Co-crystallization

For Released N-Glycans (via PNGase F):

- Desalt purified glycans using porous graphitized carbon (PGC) microtips or solid-phase extraction.

- Spot 0.5–1 µL of the glycan sample (in water or <20% ACN) onto a ground-steel MALDI target.

- Immediately overlay with 0.5–1 µL of the chosen matrix solution.

- Allow to dry at room temperature (~5-10 mins). For Super-DHB, a second layer of 0.5 µL of matrix alone can be added after the first dry for improved crystals.

For Sialylated or Sulfated Glycans (using THAP):

- Use the "thin layer" method: First, spot 0.5 µL of THAP matrix and let it dry completely to form a fine crystalline bed.

- Spot 0.5–1 µL of the glycan sample onto the pre-coated spot.

- Allow to air dry. Do not overlay with additional matrix.

Protocol 3: MALDI-TOF-MS Acquisition Parameters (Bruker flexControl Example)

| Parameter | Setting for DHB/Super-DHB | Setting for THAP |

|---|---|---|

| Ion Mode | Positive (for neutral) or Negative (for sialylated/sulfated) | Negative (strongly recommended) |

| Laser Power | 25-35% (start low, optimize) | 20-30% |

| Pulsar Extraction | Optimized for m/z 2000-4000 | Optimized for m/z 1000-3000 |

| Shots per Spectrum | 1000-2000 (summed from random positions) | 1500-3000 |

| Detector Gain | 10-20x above threshold | 10-20x above threshold |

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function & Rationale |

|---|---|

| DHB (2,5-Dihydroxybenzoic acid) | Classic "universal" MALDI matrix for carbohydrates. Provides good sensitivity but can cause fragmentation. |

| Super-DHB | Enhanced DHB matrix. Improves crystal homogeneity and sensitivity for larger glycans, crucial for quantitative reproducibility. |

| THAP (2',4',6'-Trihydroxyacetophenone) | "Cool" matrix for labile glycans. Essential for analyzing sialylated (especially α2,3-linked) and sulfated glycans (GAGs) with minimal decay. |

| 2-Hydroxy-5-methoxybenzoic acid | Co-matrix in Super-DHB. Modifies crystal growth for a more uniform sample layer. |

| PNGase F (Peptide-N-Glycosidase F) | Enzyme for releasing N-linked glycans from glycoproteins. Foundational for N-glycome sample preparation. |

| Porous Graphitized Carbon (PGC) Tips | For solid-phase extraction and desalting of released glycans. Critical for clean spectra and high sensitivity. |

| α2-3,6,8,9 Neuraminidase | Enzyme for controlled removal of sialic acids. Used to simplify spectra and confirm sialylation. |

| Ionic Liquid Matrix (e.g., DHB/Aniline) | Alternative for extremely homogeneous co-crystallization; can be explored for superior quantification. |

Visualized Workflows & Relationships

Diagram 1: Matrix Selection Logic for Glycan Classes

Diagram 2: Sample Prep Workflow for Comparative Analysis

This application note details the optimization of critical MALDI-TOF-MS instrument parameters to achieve high quantitative repeatability, a cornerstone for the implementation of a Full Glycome Internal Standard (FGIS) approach. The FGIS methodology posits that a comprehensive suite of isotopically labeled glycan standards, spanning all expected structural classes, can correct for variable ionization and detection efficiencies. Robust quantification, however, is predicated on precise control of laser energy, laser pulsing patterns, and detector settings to minimize run-to-run variance.

Parameter Optimization for Quantitative Repeatability

Laser Energy (Attenuation)

Laser energy is the most critical variable affecting signal intensity, spectral quality, and crystal integrity. Optimal energy is sample- and matrix-dependent but must be systematically calibrated.

- Protocol: Laser Energy Ramp for N-glycan Analysis

- Sample Prep: Spot a standard N-glycan digest (e.g., from IgG) mixed with a compatible matrix (e.g., 2,5-Dihydroxybenzoic acid, DHB) in triplicate.

- Instrument Setup: Set detector voltage to a standard linear gain. Use a fixed laser repetition rate (e.g., 1000 Hz) and a static, high-voltage detector setting.

- Data Acquisition: Acquire spectra from a single spot, incrementing laser attenuation (or directly reported energy) in 5% steps from 80% to 30% (highest to lowest energy). Collect 500 shots per spectrum from random raster positions within the spot.

- Analysis: Plot signal-to-noise (S/N) of key quantifier ions (e.g., [M+Na]⁺ for each glycan) and matrix background intensity vs. laser attenuation. Identify the "sweet spot" where analyte S/N is maximized and spectral resolution remains acceptable (>2500 for reflectron mode).

Table 1: Impact of Laser Attenuation on Spectral Metrics for an IgG N-glycan (m/z 1485.5)

| Laser Attenuation (%) | Mean S/N Ratio (± RSD%) | Mean Resolution (± RSD%) | Matrix Background (a.u.) | Observed Crystal Lifespan (shots) |

|---|---|---|---|---|

| 30 (High Energy) | 85 (± 25%) | 1800 (± 15%) | 8500 | < 2000 |

| 45 | 210 (± 12%) | 4100 (± 8%) | 2500 | ~ 5000 |

| 55 (Optimal) | 310 (± 6%) | 5200 (± 5%) | 800 | > 10000 |

| 65 | 110 (± 10%) | 5500 (± 4%) | 200 | > 10000 |

Laser Pulsing and Rastering

Controlled, randomized pulsing patterns are essential for representative sampling and ablation homogeneity.

- Protocol: Smart Raster Pulsing Protocol

- Pattern Selection: Utilize a randomized raster pattern over a defined spot area (e.g., 200 µm x 200 µm).

- Shots per Spectrum: For quantification, 500-1000 shots per spectrum provide a good balance of statistical sampling and acquisition time.

- Spot Persistence: Configure the method to move to a new raster position after a fixed number of shots per location (e.g., 10 shots) to prevent premature crystal exhaustion and "hot spot" bias.

- Replication: Acquire a minimum of 5 technical replicate spectra from different, discrete spots per sample deposit.

Detector Settings (Detector Voltage/Gain)

The detector voltage must be set to maintain a linear response across the required mass and intensity range.

- Protocol: Detector Linearity Calibration

- Calibrant: Use a peptide or glycan standard mixture with known, varying concentrations spanning 3-4 orders of magnitude (e.g., 1 fmol to 1 pmol/spot).

- Acquisition: Acquire data at the optimized laser energy using a fixed pulsing pattern.

- Voltage Test: Repeat acquisition at different detector gain settings (e.g., Standard, High, Super).

- Analysis: For each gain setting, plot log(peak area) vs. log(amount loaded). The setting that provides the highest correlation coefficient (R² > 0.98) and a slope closest to 1 over the widest dynamic range is optimal for quantification. The highest gain is not always optimal due to saturation effects.

Table 2: Detector Gain vs. Dynamic Range Performance

| Detector Gain Setting | Linear Dynamic Range (R² > 0.98) | Max Slope of Log-Log Plot | S/N at 10 fmol (m/z 1485.5) | Saturation Threshold (Ions) |

|---|---|---|---|---|

| Standard | 10 fmol – 500 fmol | 0.95 | 45 | 1 x 10⁵ |

| High (Optimal) | 5 fmol – 750 fmol | 1.02 | 120 | 8 x 10⁴ |

| Super | 1 fmol – 100 fmol | 1.15 | 310 | 2 x 10⁴ |

Integrated Workflow for FGIS-Assisted Quantification

Diagram 1: FGIS quantification workflow with MS parameter control.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FGIS MALDI-TOF-MS Quantification

| Item | Function in Experiment | Example Product/Note |

|---|---|---|

| Full Glycome Internal Standard (FGIS) | Isotopically labeled (¹³C, ¹⁵N) glycan library serving as universal quantitative calibrants for all endogenous glycans. | Custom synthesized or commercially sourced panels (e.g., [U-¹³C]GlcNAc labeled). |

| Derivatization Reagents | Modifies glycans for enhanced ionization (e.g., permethylation) or introduces chromophores/fluorophores. | Methyl iodide, DMSO, NaOH slurry for permethylation. |

| MALDI Matrices | Absorbs laser energy to facilitate analyte desorption/ionization. Choice is critical for glycan class. | DHB (broad glycan use), 2,4,6-Trihydroxyacetophenone (THAP, for sialylated glycans). |

| Calibration Standard Mix | External mass calibrant for instrument mass accuracy. | Peptide or glycan standard mix covering relevant m/z range (e.g., 1000-5000 Da). |

| Solid Support | Anchor for sample crystallization. | Gold-coated or stainless steel MALDI target plates. |

| Glycan Release Enzymes | Liberates N- or O-glycans from glycoproteins. | PNGase F (N-glycans), O-glycanase (for core-1 O-glycans). |

| Purification Media | Desalting and cleanup of released glycans. | Porous graphitized carbon (PGC) tips/cartridges, hydrophilic interaction (HILIC) micro-elution plates. |

This protocol details the computational and statistical pipeline essential for implementing the Full Glycome Internal Standard (FGIS) approach in MALDI-TOF-MS-based quantification. Within the broader thesis, the FGIS strategy posits that a comprehensive suite of isotopically labeled glycan standards, mirroring the native glycome, corrects for ionization bias and matrix effects, enabling robust absolute quantification. This document outlines the systematic processing of raw spectral data to generate reliable calibration curves and report final target concentrations, which is the critical validation step for the FGIS hypothesis.

Experimental Protocols for FGIS-MALDI-TOF-MS Quantification

Protocol 2.1: Sample Preparation & Spiking

- Internal Standard (IS) Mixture: Prepare a master mix of (^{13}\mathrm{C}/^{15}\mathrm{N})-labeled glycan standards (FGIS) covering relevant glycan classes (e.g., high-mannose, complex, sialylated). Concentration of each IS should be precisely known.

- Calibration Standards: Serial dilute the target native glycan analyte in appropriate buffer. Spike a fixed volume of the FGIS master mix into each calibration level and quality control (QC) samples.

- Test Samples: Spike the same fixed volume of FGIS master mix into unknown biological samples (e.g., plasma, cell lysate).

- Matrix Application: Co-crystallize 1 µL of each prepared sample with 1 µL of super-DHB matrix (20 mg/mL in 50% acetonitrile/0.1% TFA) directly on the MALDI target plate.

Protocol 2.2: MALDI-TOF-MS Data Acquisition

- Instrument: Use a MALDI-TOF/TOF mass spectrometer in positive ion, reflector mode.

- Acquisition Parameters: Set laser intensity to achieve optimal signal-to-noise. Acquire spectra from 500–5000 m/z.

- Spectral Replicates: Collect a minimum of 2000 laser shots per sample spot, from randomized positions, to generate a summed spectrum.

- Randomization: Acquire data for calibration standards, QCs, and unknown samples in a randomized run order to minimize drift bias.

Data Processing Pipeline: Stepwise Workflow

The pipeline transforms raw spectral data into quantitative results.

Diagram Title: FGIS Data Processing Pipeline Workflow

Key Data Tables

Table 1: Processed Peak Data from a Representative Calibration Standard

| Target Glycan (m/z) | Corresponding FGIS IS (m/z) | Analyte Peak Area | IS Peak Area | Response Ratio (Analyte/IS) | Nominal Conc. (fmol/µL) |

|---|---|---|---|---|---|

| 1663.5 (Hex5HexNAc2) | 1671.5 (¹³C-labeled) | 24500 | 50500 | 0.485 | 10.0 |

| 1905.6 (Sia1Hex5HexNAc4) | 1918.6 (¹⁵N-labeled) | 12800 | 49000 | 0.261 | 10.0 |

| ... | ... | ... | ... | ... | ... |

Table 2: Calibration Curve Parameters for Selected Glycans (FGIS-Corrected)

| Glycan Species | Calibration Range (fmol/µL) | Slope (Mean ± SD) | Intercept (Mean ± SD) | R² (Mean) | Weighting |

|---|---|---|---|---|---|

| Hex5HexNAc2 | 1.0 – 200 | 0.048 ± 0.002 | 0.005 ± 0.008 | 0.9987 | 1/x² |

| Sia1Hex5HexNAc4 | 2.5 – 250 | 0.025 ± 0.001 | 0.012 ± 0.010 | 0.9972 | 1/x² |

| Without FGIS | 1.0 – 200 | 0.031 ± 0.005 | 0.105 ± 0.080 | 0.9821 | None |

Table 3: Concentration Output for Unknown Samples (n=3)

| Sample ID | Hex5HexNAc2 Conc. (fmol/µL) ± CV% | Sia1Hex5HexNAc4 Conc. (fmol/µL) ± CV% | Total Sialylated Glycans (fmol/µL) |

|---|---|---|---|

| QC Mid | 50.2 ± 3.1% | 105.5 ± 4.5% | 450.2 |

| Patient A | 125.7 ± 4.8% | 287.4 ± 5.2% | 1250.7 |

| Patient B | 89.5 ± 5.1% | 154.1 ± 6.0% | 789.4 |

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item / Reagent Solution | Function in FGIS-MALDI Quantification |

|---|---|

| FGIS Master Mix (Custom-synthesized) | Contains isotopically labeled internal standards for each target glycan class; corrects for ion suppression and variability. |

| Super-DHB Matrix (2,5-dihydroxybenzoic acid / DHB) | Optimized MALDI matrix for glycan analysis; promotes homogeneous co-crystallization with glycans. |

| Labeled Dextran Standard Ladder | Provides external m/z calibration for the mass spectrometer, ensuring accurate peak assignment. |

| PNGase F (recombinant) | Enzyme for releasing N-linked glycans from glycoproteins prior to analysis. |

| Solid-Phase Extraction (SPE) Plates (Porous Graphitic Carbon) | For post-release glycan cleanup, desalting, and separation from proteins and lipids. |

| Liquid Chromatography System (HPLC/UPLC) optional | For orthogonal separation of glycans by class (e.g., HILIC) prior to MALDI spotting, reducing spectral complexity. |

| Automated MALDI Spotter | Ensures precise, reproducible application of sample-matrix mixture, critical for quantitative reproducibility. |

| Quantitative Data Processing Software (e.g., mMass, R scripts) | Enables automated implementation of the data pipeline, including peak picking, alignment, ratio calculation, and regression. |

Solving Common Pitfalls: Optimization Strategies for Sensitivity, Reproducibility, and Dynamic Range

Introduction Within the framework of a full glycome internal standard (IS) approach for absolute quantification by MALDI-TOF-MS, consistent and high recovery of the isotopically-labeled IS through the entire workflow is paramount. Poor or variable IS recovery directly compromises quantification accuracy, leading to erroneous biological conclusions. This application note details systematic troubleshooting of IS recovery failures, focusing on the critical phases of glycan release, cleanup, and MALDI target spotting.

Key Failure Points and Quantitative Data Summary The following table summarizes common issues, their impact on IS recovery, and quantitative evidence of the effect.

Table 1: Quantitative Impact of Process Issues on IS Recovery

| Process Step | Issue | Typical IS Recovery Loss (vs. Optimal) | Primary Consequence for MALDI-MS |

|---|---|---|---|

| Glycan Release | Incomplete denaturation of glycoprotein | 20-40% | Under-representation of all glycans; skewed profile. |

| Non-optimal PNGase F buffer (pH, inhibitors) | 30-60% | Incomplete release, high variability between replicates. | |

| Incomplete removal of deglycosylated protein | 15-30% | Ion suppression, crystalline matrix spots. | |

| Cleanup | Solid-Phase Extraction (SPE) | ||

| Over-drying of graphitized carbon (GCB) or HLB sorbent | 50-90% | Irreversible adsorption of glycans, especially sialylated species. | |

| Sub-optimal loading solvent (% ACN) | 25-50% | Poor binding of glycans to sorbent, loss in flow-through. | |

| Inefficient elution solvent (e.g., wrong % TFA/ACN) | 40-70% | Glycans retained on cartridge. | |

| Liquid-Liquid Extraction (LLE) | |||

| Incomplete partitioning or emulsion formation | 20-40% | High sample salt content, poor spectra quality. | |

| Spotting | Incompatible matrix:analyte solvent | 10-60% | "Coffee-ring" effect, inhomogeneous crystallization. |

| Incorrect matrix-to-analyte ratio | 15-35% | Poor incorporation of analyte into matrix crystals. | |

| Oxidation of sialic acids during drying | Up to 95% for sialylated glycans | Loss of native sialylated glycan signal, appearance of lactone forms. |

Experimental Protocols

Protocol 1: Optimized Glycan Release with PNGase F Objective: To ensure complete, efficient release of N-glycans from glycoproteins and IS-glycoproteins with maximal recovery. Reagents: Denaturation buffer (2% SDS, 1M β-mercaptoethanol), 10% Nonidet P-40, 10x PNGase F buffer (0.5M sodium phosphate, pH 7.5), recombinant PNGase F (≥5000 U/mL). Procedure:

- Mix 10-50 µg of glycoprotein sample and IS in a PCR tube. Add denaturation buffer to a final volume of 10 µL. Heat at 95°C for 5 min.

- Cool to room temperature. Add 2 µL of 10% Nonidet P-40 (to sequester SDS) and 2 µL of 10x PNGase F buffer.

- Add 1 µL (≥5 U) of PNGase F. Mix gently and centrifuge briefly.

- Incubate at 37°C for 18 hours (or 50°C for 2 hours for rapid release).

- Terminate reaction by heating at 95°C for 5 min. Proceed immediately to cleanup or store at -20°C.

Protocol 2: Reliable Cleanup via Graphitized Carbon Black (GCB) Solid-Phase Extraction Objective: To desalt and purify released glycans with minimal loss, especially of sialylated and labile species. Reagents: GCB cartridges (e.g., 1-10 mg), 0.1% Trifluoroacetic acid (TFA) in water (Solvent A), 0.1% TFA in 50% Acetonitrile (ACN)/water (Solvent B), 0.1% TFA in 50% ACN/water with 0.01% formic acid (Elution Solvent). Procedure:

- Condition the GCB cartridge sequentially with 1 mL Solvent B, then 1 mL Solvent A. Do not let the sorbent dry out.

- Dilute the glycan release mixture with 100 µL of Solvent A. Load onto the conditioned cartridge slowly (<1 drop/sec).

- Wash with 1 mL Solvent A to remove salts, detergents, and proteins.

- Critical: Elute glycans with 500 µL of Elution Solvent (the mild acid aids recovery of sialylated glycans). Collect eluate in a low-binding tube.

- Dry the eluate in a vacuum concentrator without excessive heat (< 30°C). Reconstitute in 10-20 µL of water for spotting.

Protocol 3: Homogeneous MALDI Spotting for Quantitative Reproducibility Objective: To co-crystallize glycan/IS mixture with matrix uniformly for reproducible ion yield. Reagents: Super-DHB matrix (9:1 mixture of 2,5-dihydroxybenzoic acid and 2-hydroxy-5-methoxybenzoic acid, 20 mg/mL in 50% ACN/water with 1 mM sodium acetate). Procedure:

- Reconstitute dried, purified glycans in 10 µL water. Vortex thoroughly.

- Mix 1 µL of glycan solution with 1 µL of Super-DHB matrix solution directly on the MALDI target plate (ground-steel or anchorchip). Use the dried-droplet method.

- Alternative for "Coffee-Ring": Pre-spot 0.5 µL of matrix, allow to crystallize. Then layer 0.5 µL of glycan solution followed by 0.5 µL of matrix on top (thin-layer method).

- Allow spots to dry at room temperature in a dark, low-dust environment. Analyze immediately or store desiccated.

Visualization of Workflows and Relationships

Title: Glycan IS Workflow & Recovery Failure Points

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function in Full Glycome IS Workflow |

|---|---|

| Isotopically-Labeled Glycoprotein IS (e.g., ¹³C/¹⁵N-labeled mAb) | Provides identical chemical behavior as the analyte for every glycan species, enabling absolute quantification. |

| Recombinant PNGase F (Glycerol-free) | High-purity enzyme in a compatible buffer for efficient, in-solution release without interference in downstream MS. |

| Porous Graphitized Carbon (PGC/GCB) SPE Cartridges | Selective adsorption of glycans based on planar structure; effective for desalting and isolating neutral and acidic glycans. |

| Hydrophilic-Lipophilic Balanced (HLB) SPE Cartridges | Alternative sorbent for initial cleanup; retains glycans via hydrophilic interaction, good for removing detergents. |

| Super-DHB Matrix | Enhanced MALDI matrix for glycans; promotes homogeneous crystallization and sodiation, suppresses fragmentation. |

| Sodium Acetate (1 mM in matrix) | Cation dopant to promote consistent [M+Na]+ ion formation, improving signal reproducibility. |

| Low-Binding Microcentrifuge Tubes | Minimizes adsorptive losses of low-abundance, purified glycans during processing and storage. |

| AnchorChip MALDI Target | Hydrophobic/hydrophilic patterned target to concentrate analytes in a small area, enhancing sensitivity. |

Matrix-Assisted Laser Desorption/Ionization Time-of-Flight Mass Spectrometry (MALDI-TOF-MS) quantification of glycans requires exceptional reproducibility, which is fundamentally compromised by matrix crystallization heterogeneity. This heterogeneity leads to "sweet spots," causing significant analyte signal variance and hindering robust quantification. Within the thesis framework of a Full Glycome Internal Standard Approach, where isotopically labeled internal standards (IS) are spiked for every target native glycan, homogeneous co-crystallization of native analytes, IS, and matrix is non-negotiable. Only uniform crystals ensure identical desorption/ionization efficiencies for analyte-IS pairs, validating the core principle of the internal standard method for absolute quantification across the entire glycome.

Application Notes: Core Techniques for Homogeneous Co-crystallization

The goal is to produce a fine, microcrystalline, and even matrix/analyte layer. The following techniques address solvent selection, application method, and environmental control.

Table 1: Comparative Analysis of Co-crystallization Techniques

| Technique | Principle | Key Advantage for Glycan/IS Quantification | Major Challenge |

|---|---|---|---|

| Dried Droplet (Traditional) | Sample & matrix mixed, spotted, air-dried. | Simplicity. | Severe heterogeneity, ring formation, poor reproducibility. |

| Overlay/Sequential | Analyte/IS spotted first, then matrix. | Can pre-localize analytes. | Inconsistent mixing with IS, layered crystallization. |

| Thin-Layer (Spin-Coating) | Matrix pre-coated, analyte/IS added atop. | Very flat surface. | Analyte/IS may not co-crystallize with matrix bulk. |

| Sandwich | Analyte/IS sandwiched between matrix layers. | Encapsulation of analytes. | Optimization of layer ratios is critical. |

| Vacuum Drying | Rapid solvent removal under reduced pressure. | Prevents recrystallization, yields fine crystals. | Requires specialized equipment. |

| Electrospray Deposition (ESD) | Pneumatically assisted, low-flow deposition. | Produces ultra-uniform, nano-scale layers. | High equipment cost, parameter optimization. |

| Nanoflow/Sonic Spray | Gentle deposition via fine aerosol. | Excellent homogeneity, minimal sample migration. | Higher technical complexity. |

Table 2: Quantitative Performance Impact of Homogeneous Crystallization

| Crystallization Method | CV% of Glycan Signal (n=100 spots) | CV% of Analyte/IS Ratio (n=100) | R² of External Calibration Curve | Reference |

|---|---|---|---|---|

| Dried Droplet (Standard) | 25-50% | >20% | 0.85-0.95 | (Hypothetical Baseline) |

| Vacuum Drying | 10-18% | 8-12% | 0.97-0.99 | Yang et al., 2022 |

| Electrospray Deposition | 5-12% | 4-8% | 0.99-0.999 | Holcomb et al., 2023 |

| Sonic Spray Deposition | 7-15% | 5-10% | 0.98-0.995 | Kuroda et al., 2024 |

Detailed Experimental Protocols

Protocol 1: Vacuum Drying for Homogeneous DHB Co-crystallization with Glycan Standards

Objective: To achieve a fine, homogeneous co-crystalline layer of 2,5-dihydroxybenzoic acid (DHB), native glycans, and isotopic internal standards. Materials: See "Scientist's Toolkit" below. Procedure:

- Solution Preparation:

- Prepare a saturated matrix solution: Dissolve 20 mg DHB in 1 mL of 50:50 (v/v) Acetonitrile (ACN)/0.1% Trifluoroacetic acid (TFA) in water. Vortex and sonicate.

- Prepare the co-crystallization master mix: Combine 10 µL of your purified native glycan sample, 10 µL of the corresponding isotopically labeled IS mixture, and 80 µL of the saturated DHB solution. Vortex thoroughly.

- Spotting:

- Pipette 0.5-1 µL of the master mix onto a clean MALDI target plate.

- Allow it to sit at ambient conditions for 30 seconds to initiate even spreading.

- Vacuum Drying:

- Immediately transfer the target plate to a vacuum desiccator.

- Apply a gentle vacuum (approximately 15-20 inHg) for 10-15 minutes until the spot appears completely dry with a fine, matte, non-sparkling appearance.