A Comprehensive Framework for Validating High-Throughput Glycomics Methods in Biopharmaceutical Development

This article provides a detailed protocol for the validation of high-throughput (HTP) glycomics methods, which are essential for characterizing glycosylation—a critical quality attribute of therapeutic proteins.

A Comprehensive Framework for Validating High-Throughput Glycomics Methods in Biopharmaceutical Development

Abstract

This article provides a detailed protocol for the validation of high-throughput (HTP) glycomics methods, which are essential for characterizing glycosylation—a critical quality attribute of therapeutic proteins. Aimed at researchers, scientists, and drug development professionals, the content explores the foundational principles of protein glycosylation and the pressing need for rapid analytical solutions. It delves into the core components of HTP workflows, including automated sample preparation, advanced mass spectrometry, and data analysis platforms. The guide also covers crucial troubleshooting and optimization strategies to overcome common challenges, and concludes with a rigorous framework for methodological validation and comparative performance assessment against industry standards, supporting applications from early clone selection to batch release.

The Critical Role of Glycosylation and the Drive Toward High-Throughput Analysis

Glycosylation as a Critical Quality Attribute (CQA) for Biologics

Core Concepts: FAQs on Glycosylation and CQAs

FAQ 1: What is a Critical Quality Attribute (CQA), and why is glycosylation considered one?

A Critical Quality Attribute (CQA) is a physical, chemical, biological, or microbiological property that must be maintained within an appropriate limit, range, or distribution to ensure the desired product quality, safety, and efficacy [1]. Glycosylation is a CQA because the specific patterns of sugar molecules (glycans) attached to a protein therapeutic directly influence its safety, potency, and stability [1] [2]. For monoclonal antibodies, glycosylation (particularly in the Fc region) can modulate effector functions like Antibody-Dependent Cell-mediated Cytotoxicity (ADCC) and Complement-Dependent Cytotoxicity (CDC) [3] [4] [2]. The presence or absence of a single sugar, such as fucose, can significantly enhance ADCC activity, thereby impacting the drug's therapeutic potency [4].

FAQ 2: At what stages of biologics development is glycosylation analysis most critical?

Glycan analysis is essential at multiple points throughout the biopharmaceutical lifecycle [3]:

- Early Clone Selection: High-throughput screening to identify cell lines that produce proteins with the desired glycosylation patterns.

- Process Development and Optimization: Ensuring consistent glycosylation profiles under different production conditions (e.g., culture media, bioreactor parameters).

- Batch-to-Batch Consistency Control: Monitoring product quality for lot release.

- Comparative Assessments: Demonstrating similarity between biosimilars and their reference originator drugs.

FAQ 3: What are the main analytical challenges in glycan analysis?

Glycan analysis is inherently complex due to several factors [5] [2]:

- Heterogeneity: Glycans are not template-driven, leading to a multitude of different structures on a single protein.

- Isobaric Structures: Many glycans have the same mass but different structures, requiring advanced separation techniques for resolution.

- Lack of Chromophores: Native glycans cannot be detected by UV, necessitating derivatization with fluorescent tags for sensitive detection.

- Complex Data Analysis: Mass spectrometry data is dense and requires sophisticated bioinformatics tools for interpretation [6].

Troubleshooting Guides: Common Experimental Issues

Problem: Low Throughput in Glycan Profiling

| Symptom | Possible Cause | Solution |

|---|---|---|

| Long sample preparation and analysis times; inability to process large sample sets. | Manual, multi-step purification protocols; serial LC-MS analysis. | Implement a 96-well-plate compatible purification method using materials like CL-4B Sepharose beads to enable parallel processing of at least 192 samples [3]. Adopt high-throughput MALDI-TOF-MS, which can analyze hundreds of samples in minutes [3]. Utilize multiplexed labeling tags (e.g., 12-plex SUGAR tags) to pool and analyze multiple samples in a single LC-MS/MS injection [7]. |

Problem: Poor Quantitative Reproducibility

| Symptom | Possible Cause | Solution |

|---|---|---|

| High coefficients of variation (CV) in glycan abundance measurements between replicates. | Inefficient or inconsistent sample cleanup; ion suppression in MS; lack of robust internal standards. | Employ a full glycome internal standard approach. This involves generating a library of isotope-labeled glycans that mirror the native glycan pool, significantly improving quantification precision by providing a matched internal standard for each analyte [3]. Automated liquid handling workstations can also minimize manual operation variability [3]. |

Problem: Inefficient and Cumbersome Data Analysis

| Symptom | Possible Cause | Solution |

|---|---|---|

| Spending excessive time on manual data processing and verification; difficulty interpreting complex MS data. | Use of multiple, non-integrated software tools that require extensive manual file adjustment and lack full automation [6]. | Implement an automated data processing pipeline like GlycoGenius. This open-source tool automates glycan identification, quantification, and data visualization, seamlessly guiding researchers from raw data to publication-ready figures and significantly reducing processing time [6]. |

The performance of a high-throughput glycosylation screening method based on MALDI-TOF-MS with an internal standard approach was rigorously validated, yielding the following data [3]:

Table 1: Key Validation Parameters for a High-Throughput Glycosylation Screening Method

| Parameter | Result | Details |

|---|---|---|

| Precision (Repeatability) | Average CV of ~10.41% | CV range: 6.44% - 12.73% for six replicates in one day. |

| Precision (Intermediate Precision) | Average CV of ~10.78% | CV range: 8.93% - 12.83% over three different days. |

| Linearity | R² > 0.99 (average 0.9937) | Demonstrated across a 75-fold concentration gradient. |

| Throughput | Up to 192 samples per experiment | Enabled by 96-well-plate compatibility and rapid MALDI-TOF-MS analysis. |

Table 2: Comparison of Quantitative Glycomics Tagging Technologies

| Tagging Technology | Multiplexing Capacity | Key Principle | Throughput Advantage |

|---|---|---|---|

| SUGAR Tags [7] | 12-plex | Isobaric labeling with reporter ions released in MS/MS for quantification. | Allows pooling and relative quantification of 12 samples in a single LC-MS/MS run. |

| 2-Aminobenzamide (2-AB) [2] | 1-plex (non-multiplexed) | Fluorescent derivatization via reductive amination for detection. | Established database; requires individual sample analysis. |

| RapiFluor-MS [2] | 1-plex (non-multiplexed) | Rapid, MS-sensitive labeling via NHS-carbamate chemistry. | Fast labeling process and enhanced MS ionization. |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Materials for High-Throughput Glycan Analysis

| Reagent / Material | Function / Application | Example Use Case |

|---|---|---|

| PNGase F [7] [2] | Enzyme that releases N-linked glycans from glycoproteins for subsequent analysis. | Standard protocol for cleaving N-glycans from monoclonal antibodies like trastuzumab prior to purification and labeling [3] [7]. |

| CL-4B Sepharose Beads [3] | A solid-phase matrix for hydrophilic interaction liquid chromatography (HILIC) purification in a 96-well format. | Replaces manual cotton HILIC SPE tips to enable high-throughput, automated cleanup of released glycans [3]. |

| Isobaric Labels (e.g., SUGAR Tags) [7] | Chemical tags for multiplexed relative quantification of glycans by mass spectrometry. | Labeling released N-glycans from different IgG subtypes or cell line treatments for pooled, relative quantification [7]. |

| Full Glycome Internal Standard [3] | A library of stable isotope-labeled glycans used for precise normalization and quantification. | Spiked into every sample to correct for preparation and ionization variability, improving quantitative accuracy [3]. |

| Porous Graphitized Carbon (PGC) [5] [8] | Stationary phase for LC separation of glycans, providing high resolution and structural insight. | Used in nanoLC-MS systems for deep glycome profiling, capable of separating isomeric structures [8]. |

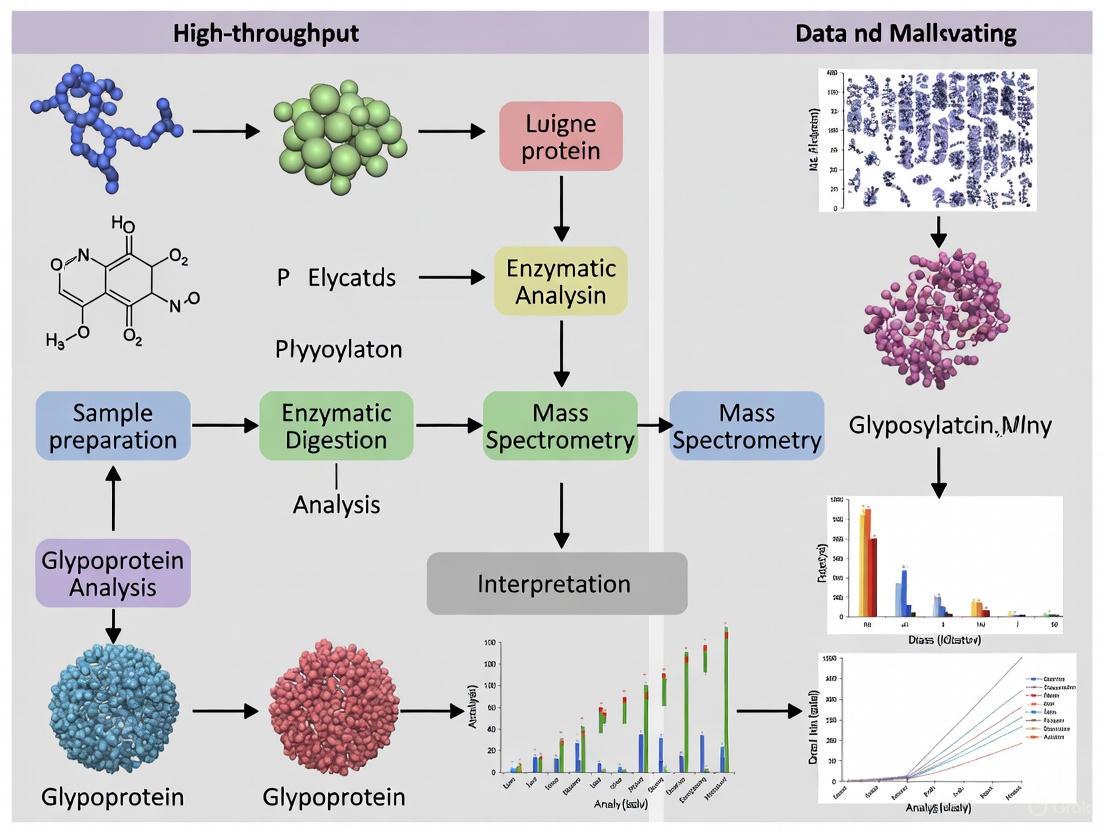

Workflow Visualization

The following diagram illustrates an integrated high-throughput workflow for glycosylation analysis, combining sample preparation, MS analysis, and automated data processing.

High-Throughput Glycomics Workflow for CQA Assessment

For a more comprehensive structural analysis, the glycomics-guided glycoproteomics workflow provides deeper insights into the glycoproteome.

Integrated Glycomics-Guided Glycoproteomics Workflow

This technical support center provides targeted guidance for researchers developing high-throughput (HTP) glycomics methods to support the development of biosimilar medicines within a Quality by Design (QbD) framework. Evolving regulatory landscapes are accelerating biosimilar development, emphasizing the need for robust, efficient analytical techniques to demonstrate similarity [9]. Glycomics is critical here, as a protein's glycan profile is a Critical Quality Attribute (CQA) with a direct impact on safety and efficacy [10] [11]. The protocols and troubleshooting guides below address specific challenges in validating these sensitive, high-throughput methods.

Frequently Asked Questions (FAQs)

Q1: Why is high-throughput glycomics essential for biosimilar development?

A: Regulatory agencies require extensive analytical characterization to prove a biosimilar is "highly similar" to its reference product [9] [12]. Glycosylation is a major source of heterogeneity and can profoundly affect a therapeutic protein's stability, bioactivity, and immunogenicity [10] [11]. High-throughput glycomics enables the analysis of thousands of samples needed for QbD studies to define the design space, establish comparability, and ensure consistent product quality [11].

Q2: How do QbD principles apply to glycomics method development?

A: In QbD, method development is systematic and science-based, just like product development. The table below outlines how key QbD elements translate to analytical methods.

Table: Applying QbD Principles to Glycomics Method Development

| QbD Element | Application to Glycomics Method Validation |

|---|---|

| Quality Target Product Profile (QTPP) | Define the method's goal: e.g., "Quantify 20 key N-glycan structures from a mAb with ≤15% RSD." |

| Critical Quality Attributes (CQAs) | Identify critical method performance metrics: accuracy, precision, sensitivity, linearity, and robustness. |

| Critical Process Parameters (CPPs) | Determine key steps affecting results: e.g., deglycosylation time, labeling efficiency, chromatographic gradients. |

| Control Strategy | Implement system suitability tests, reference standards, and control charts to ensure ongoing method performance. |

| Risk Management | Proactively identify and mitigate potential failure points (e.g., sample degradation, enzyme activity loss) [13] [14]. |

Q3: What are the most common bottlenecks in HTP glycomics workflows, and how can they be overcome?

A: The primary bottlenecks are sample preparation and data analysis.

- Sample Preparation: Traditional methods are manual and time-consuming. Solution: Automate using liquid handling robots and integrated kit-based workflows [10] [11]. Magnetic bead-based purification (e.g., for released N-glycans) can also significantly increase speed and be easily automated [11].

- Data Analysis: Glycan structural heterogeneity and large datasets create challenges. Solution: Utilize bioinformatics tools like GlyCompareCT to reduce data sparsity and enhance statistical power by decomposing glycans into substructures (glycomotifs) [15]. Leverage databases (GlyTouCan, UniCarbKB) and software (GlycoDigest, autoGU) for automated structural assignment [10] [16].

Troubleshooting Guides

Issue 1: High Data Sparsity and Poor Statistical Power in Glycan Profiling

Problem: Glycan abundance data is sparse, with many zeros, making it difficult to perform robust statistical comparisons between biosimilar and reference product batches.

Investigation: Check the percentage of missing or zero-value data points in your abundance table. If sparsity is high (e.g., >30%), statistical correlation between samples will be low.

Resolution: Implement a data transformation tool.

- Protocol: Using GlyCompareCT for Data Reduction

- Input: Prepare your glycan abundance table (e.g., from LC-MS or CE).

- Processing: Run the GlyCompareCT command-line tool to decompose quantified glycan structures into a minimal set of non-redundant substructures, or "glycomotifs" [15].

- Output: Obtain a new abundance table based on glycomotifs. This table is inherently less sparse and reveals hidden biosynthetic relationships.

- Verification: Confirm that the correlation between sample profiles has increased, leading to higher statistical power for detecting differences [15].

Issue 2: Inconsistent Glycan Release and Labeling in a 96-Well Plate Format

Problem: High inter-sample variability in glycan signal due to inefficient or inconsistent enzymatic release and fluorescent labeling.

Investigation: Review the denaturation and enzymatic digestion steps. Inconsistent protein denaturation is a common root cause of variable deglycosylation efficiency.

Resolution: Adopt an optimized, automated protocol.

- Protocol: HTP N-Glycan Sample Preparation for mAbs

- Denaturation/Reduction: Pipette 10 µL of mAb solution (1-2 mg/mL) into a 96-well plate. Add 10 µL of denaturation/reduction buffer. Seal the plate and incubate at 65°C for 20 minutes [11].

- Enzymatic Release: Add a pre-dispensed unit dose of PNGase F enzyme to each well. Seal the plate and incubate at 37°C for 2 hours. Using a hydrophobic PVDF membrane filter plate can expedite this step [11].

- Fluorescent Labeling: Directly add a fluorescent tag (e.g., 2-AB or APTS) to the well using a robotic liquid handler. Incubate at 65°C for 1-2 hours [11].

- Clean-up: Purify labeled glycans using a 96-well HILIC filter plate or magnetic beads with a carboxylated coating [11] [10].

- Verification: Include a system suitability standard (e.g., a commercial mAb) in each plate run to monitor the consistency of the entire preparation workflow.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table: Key Reagents for HTP Glycomics Workflows

| Item | Function | Example Application in Biosimilar Analysis |

|---|---|---|

| PNGase F | Enzyme for releasing N-linked glycans from glycoproteins. | Core step for preparing N-glycans from monoclonal antibody therapeutics for profiling [11]. |

| Fluorescent Labels (2-AB, APTS) | Derivatization agents for detecting released glycans in HPLC (2-AB) or CE-LIF (APTS). | Enables highly sensitive quantification of glycan profiles; APTS allows multiplexed CGE-LIF for parallel analysis of 48-96 samples [11]. |

| HILIC Magnetic Beads | Solid-phase for purifying and concentrating released, labeled glycans. | Automation-friendly cleanup method to reduce hands-on time and increase throughput and reproducibility [11]. |

| Glycan Reference Standards | Characterized glycan mixtures with known abundances and structures. | Essential for system suitability testing, calibrating instruments, and validating method performance (accuracy, retention time) [10]. |

| Bioinformatics Tools (GlyCompareCT) | Software for processing and interpreting complex glycan abundance data. | Decomposes glycan structures to reduce data sparsity, increase statistical power, and elucidate biosynthetic trends for comparability assessment [15]. |

Workflow and Relationship Diagrams

HTP Glycomics QbD Workflow

Biosimilar Development & Glycomics

Frequently Asked Questions (FAQs)

Q1: What are the critical high-throughput needs in biopharmaceutical glycosylation analysis? High-throughput glycomics is essential at multiple stages of biologics development. Key needs include rapid clone selection during cell line development, process optimization to ensure consistent glycosylation under various production conditions, comparability assessments between biosimilars and originator drugs, and rigorous batch release and stability testing to ensure product consistency over time. These applications require the analysis of hundreds to tens of thousands of samples, demanding methods that are not only fast but also highly precise and reproducible [3] [11].

Q2: Which analytical techniques are best suited for high-throughput glycan profiling? Several automated platforms support high-throughput glycomics:

- MALDI-TOF-MS: Offers exceptionally rapid analysis, capable of processing hundreds of samples within minutes. When coupled with a full glycome internal standard approach, it achieves high quantitative precision (CV ~10%) and broad linearity (R² > 0.99) [3].

- Liquid Chromatography (UHPLC/HPLC): Provides good quantification, reproducibility, and separation of glycan isomers. Throughput is enhanced by automated sample preparation in 96-well plates [11].

- Multiplexed Capillary Gel Electrophoresis with Laser-Induced Fluorescence (CGE-LIF): Allows parallel analysis of 48 to 96 samples. One optimized workflow reports a hands-on time of just 2.5 hours for 96 samples [11].

Q3: How can I improve the quantitative accuracy of my high-throughput MALDI-TOF-MS glycomics? Incorporate a full glycome internal standard approach. This technique involves creating a library of isotope-labeled internal standards that mirror the native glycans in your samples. Each native glycan is quantified by the ratio of its signal intensity to that of its corresponding internal standard. This method corrects for signal variability, significantly improving precision. It has been demonstrated to accurately reflect selective changes in glycan abundance, even for low-abundance species, and enables absolute quantification when used with an external standard curve [3].

Q4: What are common pitfalls in maintaining sialic acid stability during sample preparation? Sialic acids are labile and require careful handling. Key precautions include:

- Avoid acidic pH and elevated temperatures. Maintain pH between 6-9 and keep temperatures below 30°C during sample processing.

- Use gentle drying techniques. Centrifugal or rotary evaporation should be performed below 25°C. Lyophilization (freeze-drying) is often a safer alternative, though care must be taken to avoid sample loss when releasing the vacuum.

- Protect from light during storage and processing, especially when using fluorescent labels [17].

Troubleshooting Guides

Issue 1: Poor Repeatability and Intermediate Precision

Problem: High coefficients of variation (CV) in replicate glycan analyses.

| Investigation Step | Action/Acceptance Criteria |

|---|---|

| Internal Standard | Verify use of a full glycome internal standard for MS-based methods. Target CV should be ≤15%, with ~10% achievable [3]. |

| Purification | Ensure solid-phase extraction (e.g., Sepharose HILIC in 96-well plates) is consistent and fully automated to minimize manual error [3]. |

| Sample Handling | Confirm consistent incubation times, temperatures, and reagent volumes across all samples in the batch [11]. |

Issue 2: Inadequate Linearity and Dynamic Range

Problem: The method fails to provide a linear response across the expected concentration range of glycans.

| Investigation Step | Action/Acceptance Criteria |

|---|---|

| Calibration Curve | Validate over a wide concentration range (e.g., 75-fold). Aim for linear regression R² values >0.99 [3]. |

| Internal Standard Suitability | Confirm the internal standard concentration is within the linear range for all target glycan abundances [3]. |

| Detector Saturation | Check that the highest concentration standards do not saturate the detector (e.g., MS or fluorescence) [11]. |

Issue 3: Low Sialic Acid Recovery

Problem: Unstable sialic acid levels, leading to inaccurate quantification of sialylated glycans.

| Investigation Step | Action/Acceptance Criteria |

|---|---|

| pH and Temperature | Scrutinize all steps for exposure to acidic pH combined with heat. Adhere to a pH of 6-9 and temperatures <30°C [17]. |

| Drying Method | Switch from centrifugal evaporation at room temperature to lyophilization for glycan samples post-labeling [17]. |

| Buffer Interference | For direct sialic acid analysis, perform a buffer blank. For complex formulations, consider a buffer exchange into water using a 10 kDa molecular weight cut-off filter [17]. |

Quantitative Method Performance Standards

Table 1: Key validation parameters for high-throughput glycomics methods based on published data.

| Performance Parameter | Target Performance | Experimental Protocol |

|---|---|---|

| Repeatability | Average CV of ~10% for 6 replicates [3] | Process six replicate glycoprotein samples (e.g., trastuzumab) through the entire workflow—from release and labeling to purification and analysis—on a single day. |

| Intermediate Precision | Average CV of ~11% over 3 days [3] | Analyze the same glycoprotein standard (e.g., 12 samples of trastuzumab) over three different days to capture inter-day variability. |

| Linearity | R² > 0.99 over a 75-fold concentration range [3] | Create a dilution series of the glycan sample with a 75-fold concentration gradient. Process and analyze all samples in a single batch to construct the calibration curve. |

| Throughput | 192+ samples in a single experiment [3] | Implement a fully 96-well plate-compatible workflow for all steps: glycan release, purification with Sepharose HILIC SPE, fluorescent labeling, and final analysis by MALDI-TOF-MS or LC. |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key reagents and materials for high-throughput glycomics workflows.

| Item | Function/Application | High-Throughput Consideration |

|---|---|---|

| CL-4B Sepharose Beads | Hydrophilic interaction liquid chromatography (HILIC) solid-phase extraction for glycan purification [3] | Enables 96-well plate compatibility and automation, replacing manual methods like cotton HILIC SPE. |

| Full Glycome Internal Standard | Isotope-labeled (e.g., +3 Da) glycan library for precise quantification in MS [3] | Corrects for MS signal variability, enabling high-precision (CV ~10%) and absolute quantification. |

| Fluorescent Labels (2-AB, APTS) | Tagging released glycans for detection by UHPLC (2-AB) or multiplexed CE (APTS) [11] [17] | APTS labeling coupled with multiplexed CGE-LIF allows parallel analysis of 48-96 samples. |

| Magnetic Beads (Carboxyl-coated) | Capture of released N-glycans via ionic interaction for rapid sample clean-up [11] | Facilitates automatable and rapid sample preparation in a 96-well format, reducing hands-on time. |

| PNGase F | Enzyme for releasing N-linked glycans from glycoproteins for analysis [18] | Can be applied in 96-well formats using hydrophobic PVDF membrane plates or in-solution with magnetic bead capture. |

High-Throughput Glycomics Workflow

The following diagram illustrates the integrated stages of a high-throughput glycomics workflow, from initial sample preparation to final data analysis.

High-Level HTP Glycomics Workflow

Internal Standard Quantification Logic

This diagram outlines the decision-making process for implementing internal standard quantification to improve data precision.

Internal Standard Decision Logic

This section addresses common questions regarding the selection and application of core high-throughput (HTP) glycomics technologies.

FAQ 1: What are the primary strengths of each HTP glycomics technology? The three core technologies offer complementary advantages [11] [19]:

- Multiplexed Capillary Electrophoresis (CE) excels in rapid, high-resolution separation of charged glycans, making it ideal for analyzing large sample cohorts. Its high repeatability is excellent for quantifying major glycan species.

- Liquid Chromatography-Mass Spectrometry (LC-MS) provides superior structural separation, particularly for isomeric glycans, by combining chromatographic retention time with mass information. It offers good quantification and reproducibility.

- Matrix-Assisted Laser Desorption/Ionization Time-of-Flight Mass Spectrometry (MALDI-TOF-MS) achieves the highest analytical throughput and is highly effective for obtaining compositional information on complex glycans, especially when combined with linkage-specific derivatization techniques.

FAQ 2: When comparing throughput, which method is fastest? Throughput involves both sample preparation and analysis time [11] [19]. MALDI-TOF-MS generally has the fastest analysis time. Multiplexed CE can analyze 48-96 samples in parallel. While LC-MS run times per sample can be longer, throughput is enhanced by using automated sample preparation and ultra-high-performance liquid chromatography (UHPLC).

FAQ 3: What are the major challenges in HTP glycomics data analysis? Glycomics data is often complex and presents specific challenges, including data sparsity, the structural non-independence of related glycans, and the presence of many isomeric structures that are difficult to resolve [15] [6]. Advanced bioinformatics tools are essential to decompose glycan structures into substructures for more powerful statistical analysis and to automate the identification and quantification process from raw data.

FAQ 4: How can I improve the statistical power of my glycomics study?

To enhance statistical power, consider using tools like GlyCompareCT, which decomposes quantified glycan structures into a minimal set of substructures called "glycomotifs" [15]. This process reduces data sparsity and explicitly accounts for biosynthetic relationships between glycans, increasing correlation and the robustness of downstream statistical analyses.

Troubleshooting Guides & Performance Metrics

Table 1: Troubleshooting Common Experimental Issues

| Technology | Common Issue | Possible Cause | Recommended Solution |

|---|---|---|---|

| All Platforms | High background noise | Incomplete purification of labeled glycans | Optimize solid-phase purification using 96-well hydrophilic filter plates or magnetic beads for cleaner samples [11]. |

| Low signal intensity | Inefficient glycan release or labeling | Use robotic liquid handlers and optimized reagent kits (e.g., rapid deglycosylation kits) to improve reproducibility and efficiency [11] [20]. | |

| MALDI-TOF-MS | Poor repeatability | Inhomogeneous co-crystallization of matrix-analyte | Ensure sample and matrix are spotted homogeneously; use automated spotters. Superior repeatability is found with CGE-LIF and LC-MS [19]. |

| Inability to resolve isomers | Limitation of MS without prior separation | Couple with offline LC or CE separation, or use linkage-specific sialic acid esterification to differentiate sialic acid linkages [19]. | |

| LC-MS / UHPLC | Long sample preparation | Labor-intensive manual protocols | Automate steps using a 96-well plate format and platforms like a PVDF membrane filter plate for deglycosylation, reducing hands-on time [11]. |

| Multiplexed CE | Capillary clogging | Sample debris or precipitation | Ensure samples are properly purified; implement rigorous flushing protocols between runs. |

Table 2: Quantitative Method Comparison for Serum N-Glycomics

The following table summarizes a direct comparison of the three HTP methods applied to the same set of human serum samples, highlighting their performance characteristics [19].

| Performance Metric | Multiplexed CGE-LIF | HILIC-UHPLC-FLD | MALDI-TOF-MS |

|---|---|---|---|

| Throughput | High (48 samples parallel) | Medium | Very High |

| Repeatability | Best | Best | Good |

| Structural Separation (Low-complexity glycans) | Best | Best | Limited |

| Compositional Info (High-complexity glycans) | Limited | Limited | Best |

| Key Application Insight | Revealed changes in α1,3- and α1,6-branch galactosylation | Revealed changes in α1,3- and α1,6-branch galactosylation | Established linkage-specific sialylation differences |

Experimental Workflows for High-Throughput Glycomics

The following workflow integrates sample preparation and analysis steps for robust HTP glycomics.

Diagram: High-Throughput Glycan Analysis Workflow

Detailed Protocol for HTP N-Glycan Sample Preparation and Analysis [11]

- Sample Denaturation: Dilute the glycoprotein sample (e.g., therapeutic antibody or serum) in a denaturing buffer.

- Glycan Release: Transfer the sample to a hydrophobic Immobilon-P PVDF membrane filter plate. Add PNGase F enzyme to release N-glycans. Incubate to allow for complete deglycosylation.

- Fluorescent Labeling: Collect the released glycans and label them with a fluorescent dye.

- For LC-MS: Use 2-aminobenzamide (2-AB).

- For Multiplexed CE: Use 8-aminopyrene-1,3,6-trisulfonic acid (APTS).

- Purification: Purify the labeled glycans to remove excess dye and salts. This can be done efficiently using a 96-well hydrophilic filter plate or magnetic beads with carboxylated coatings.

- HTP Analysis:

- LC-MS Analysis: Inject the purified sample onto a UHPLC system coupled to a mass spectrometer. Use hydrophilic interaction liquid chromatography (HILIC) for separation.

- Multiplexed CE Analysis: Load the sample onto a DNA sequencer-equipped CGE-LIF system. Analyze 48-96 samples in parallel with a hands-on time of approximately 2.5 hours for 96 samples.

- MALDI-TOF-MS Analysis: Spot the purified sample mixed with an appropriate matrix onto a target plate. Acquire mass spectra.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions for HTP Glycomics

| Reagent / Material | Function in Workflow | Key Consideration |

|---|---|---|

| PNGase F Enzyme | Enzymatically releases N-linked glycans from glycoproteins. | Critical for complete release to ensure accurate quantification [11]. |

| Fluorescent Dyes (2-AB, APTS) | Tags released glycans for sensitive detection in FLD, LIF, and MS. | APTS provides a charge for CE separation. 2-AB is common for HILIC-UHPLC [11] [19]. |

| Hydrophilic Filter Plates / Magnetic Beads | High-throughput purification and clean-up of released and labeled glycans. | Enables automation, reduces labor intensity, and is cost-effective for large sample numbers [11]. |

| PVDF Membrane Plates | Platform for immobilizing glycoproteins for efficient enzymatic release and washing. | Streamlines the release process in a 96-well format [11]. |

| Linkage-Specific Esterification Reagents | Chemically modifies sialic acids to differentiate α2,3- and α2,6-linkages in MALDI-TOF-MS. | Enables detailed structural analysis of sialylation, important for biology and biopharmaceuticals [19]. |

Advanced Data Analysis Pathways

Modern glycomics requires robust computational tools to handle data complexity. The pathway below outlines a streamlined process for data analysis.

Diagram: Glycomics Data Analysis Pathway

Description of the Data Analysis Workflow:

- Raw Data Processing: Tools like

GlycoGeniuscan automatically process raw data from LC-MS, CE-MS, or MALDI-TOF-MS experiments. This includes constructing glycan libraries, identifying putative glycan signals, creating extracted ion chromatograms/electropherograms, annotating monoisotopic peaks, and quantifying peaks based on the area under the curve [6]. - Data Decomposition: The resulting glycan abundance table is often sparse and contains structurally non-independent entities.

GlyCompareCTprocesses this table to decompose all identified glycan structures into a minimal set of substructures, known as "glycomotifs" [15]. - Statistical Analysis: The resulting glycomotif abundance table is less sparse and better captures biosynthetic relationships. This table is then used for robust downstream statistical analyses, such as differential expression analysis between sample groups (e.g., healthy vs. diseased), using specialized suites of methods available in packages like

glycowork[21].

Building and Implementing a Robust High-Throughput Glycomics Workflow

Troubleshooting Guides and FAQs

Common Problems in Automated Magnetic Bead Handling

This section addresses frequent issues encountered when using liquid handling robots for magnetic bead-based protocols in 96-well plates.

FAQ: Why is my bead recovery low or inconsistent, especially with small volumes?

Low bead recovery can critically impact yields in applications like nucleic acid extraction or glycan cleanup. The causes and solutions are often related to the physical handling of the beads [22].

- Problem: Incomplete bead resuspension during washing.

- Solution: Ensure the automated mixing method is sufficient to fully disperse the bead pellet. Visually confirm that beads are fully resuspended during wash steps to prevent aggregates from trapping contaminants [23].

- Problem: Bead loss during transfers in particle-moving systems (e.g., KingFisher-style).

- Solution: For particle-moving robots, ensure the magnetic rods are properly engaging and disengaging. Optimize the delay time after rod immersion to allow full bead release before mixing [22].

- Problem: Beads are not fully immobilized during washing on liquid handlers.

- Solution: Calibrate the magnetization time on your liquid handler. Ensure the magnetic module is fully engaged and that the platform is level. For small volumes (< 50 µL), consider splitting the reaction across multiple wells to increase the surface area for bead capture [22].

FAQ: How can I prevent clogging when automatically dispensing magnetic beads?

Clogged dispensers are a major point of failure in walk-away automation runs [22].

- Problem: Bead settling and PEG precipitation in dispensing lines.

- Solution: Use a reagent reservoir that continuously mixes the bead solution to keep it in suspension. For long runs, consider pre-mixing beads with an equal volume of a stabilizing solution like glycerol to prevent settling. Ensure that the system's tubing is securely fastened to prevent it from working loose [22].

- Problem: Dried beads clogging the dispenser nozzle.

- Solution: Program regular system purges with a buffer or water between bead dispensing steps if the instrument allows it. For systems using tips, change tips after dispensing beads [22].

FAQ: What are the main causes of high background or contamination in my assay?

Contamination can lead to inaccurate quantification in downstream steps like qPCR or mass spectrometry.

- Problem: Insufficient washing.

- Solution: Increase the number of wash cycles or the volume of wash buffer. Program the robot to perform a "soak" step where the wash buffer is allowed to incubate with the beads for 20-30 seconds before aspiration. Always ensure the plate is thoroughly tapped dry on absorbent tissue after washing [24] [25].

- Problem: Residual ethanol from wash buffers.

- Solution: Optimize the drying time after the final wash. While insufficient drying leaves ethanol that inhibits elution, over-drying makes nucleic acids difficult to resuspend. A room temperature drying time of 5-10 minutes is a good starting point; adjust based on bead type and volume [23].

- Problem: Cross-contamination between wells.

- Solution: Use fresh plate sealers for each incubation step and change pipette tips after each liquid transfer. For liquid handlers, utilize an air gap in the pipette tip to prevent drips from contaminating adjacent wells [24] [26].

Optimizing Liquid Handler Performance

The accuracy of your liquid handler is fundamental to assay precision.

FAQ: My pipetting accuracy is poor for viscous reagents. How can I improve it?

Viscous liquids, like certain preservation media or glycerol solutions, require special pipetting parameters [23].

- Solution: Define custom liquid classes on your robotic platform for reagents of different viscosities and densities. Techniques like pre-wetting tips (pipetting the liquid 2-3 times before aspirating the final volume) and using positive displacement tips can significantly improve accuracy. For difficult liquids, immerse the pipette tip in the liquid layer during dispensing to improve volume accuracy [23].

FAQ: How do I manage edge effects in a 96-well plate?

Wells on the edge of the plate can evaporate faster than interior wells, leading to concentration discrepancies.

- Solution: Always use a plate sealer during all incubation steps. Avoid stacking plates during incubation to ensure even temperature distribution. If possible, do not use the outermost wells of the plate for critical samples or standards [24] [25].

Experimental Protocol: Automated N-Glycan Sample Preparation for Glycomics

This protocol is adapted for a liquid handling robot and is based on high-throughput methods used for the quality control of therapeutic proteins like trastuzumab [27] [28].

Title: Automated High-Throughput Release and Cleanup of N-Glycans in a 96-Well Plate

1. Principle: Glycoproteins are denatured and immobilized in a 96-well filter plate. N-Glycans are enzymatically released with PNGase F, purified using magnetic bead-based hydrophilic interaction liquid chromatography (HILIC-SPE), and eluted for downstream analysis by MALDI-TOF-MS [27] [28].

2. Materials:

- Protein A/G Coated Magnetic Beads: For immobilizing antibody therapeutics.

- PNGase F Enzyme: For releasing N-glycans.

- Sepharose CL-4B HILIC Magnetic Beads: For glycan purification. These are preferred for 96-well compatibility over other HILIC materials [27].

- 96-Well Filter Plate (e.g., 0.45 µm PVDF).

- 96-Well Deep Well Plate (2 mL capacity).

- Liquid Handling Robot with a magnetic module and temperature control.

- Trifluoroacetic Acid (TFA) and Acetonitrile (ACN): For sample preparation and elution.

3. Workflow Diagram:

4. Procedure:

- Protein Immobilization: Transfer 10-50 µg of monoclonal antibody (e.g., trastuzumab) per well to a 96-well protein A/G plate. Incubate on the robot with shaking for 30 minutes at room temperature to allow binding [27].

- Denaturation: Add a denaturation buffer (e.g., containing 1% SDS) to each well. Mix and incubate at 65°C for 10 minutes with the heater-shaker module.

- Enzymatic Release: Add a master mix containing PNGase F in a non-inhibitory buffer (e.g., with NP-40 to neutralize SDS). Incubate at 37°C for 3 hours with shaking to release N-glycans [27].

- Bead-Based Cleanup:

- Transfer: Transfer the released glycan solution to a new deep-well plate containing a pre-dispensed slurry of Sepharose HILIC magnetic beads [27].

- Binding: Mix thoroughly for 10 minutes to allow glycans to bind to the beads.

- Wash: Engage the magnetic module. Once the supernatant is clear, aspirate and discard it. Wash the beads twice with 1 mL of 95% ACN containing 1% TFA [27].

- Elute: Fully dry the beads by air drying for 5-10 minutes. Disengage the magnet and elute the purified glycans by resuspending the beads in 50 µL of ultrapure water. Engage the magnet and transfer the eluate containing the glycans to a clean MS sample plate [27].

5. Expected Outcomes: This method has demonstrated high precision with an average coefficient of variation (CV) of ~10% for major glycan species and excellent linearity (R² > 0.99) across a 75-fold concentration gradient, making it suitable for quantitative glycomics and biosimilarity testing [27].

Performance Data Table

The table below summarizes the typical performance metrics you can expect from a well-optimized, automated glycan preparation method.

Table 1: Typical Performance Metrics for Automated Glycan Preparation [27]

| Performance Metric | Result | Experimental Details |

|---|---|---|

| Repeatability (CV) | 6.44% - 12.73% (Avg. 10.41%) | Six replicate analyses of trastuzumab on a single day. |

| Intermediate Precision (CV) | 8.93% - 12.83% (Avg. 10.78%) | Analyses conducted over three separate days. |

| Linearity (R²) | > 0.99 | Evaluated across a 75-fold concentration gradient. |

| Throughput | 192 samples per experiment | Based on 96-well plate format and parallel processing. |

The Scientist's Toolkit

Table 2: Essential Reagents and Materials for High-Throughput Automated Sample Prep

| Item | Function in the Protocol |

|---|---|

| Sepharose CL-4B HILIC Beads | Magnetic beads used for the purification and enrichment of released glycans; chosen for their 96-well plate compatibility [27]. |

| Full Glycome Internal Standard | An isotopically labeled glycan library added to samples to enable precise relative quantification by correcting for ionization fluctuations in MS [27]. |

| PNGase F Enzyme | The standard enzyme for efficiently releasing N-linked glycans from glycoproteins for analysis [27] [28]. |

| Protein A/G Magnetic Beads | Used to immobilize and purify antibody therapeutics from complex matrices prior to glycan release, streamlining the workflow [28]. |

| VOYAGER Adjustable Tip Spacing Pipette | An automated pipette that allows simultaneous transfer of samples from various labware (e.g., tubes) to 96-well plates without manual re-gripping, minimizing errors [26]. |

| Liquid Handling Robot with Magnetic Module | The core automation unit that performs liquid transfers, mixing, temperature control, and magnetic bead manipulation in a pre-programmed, walk-away fashion [23]. |

Glycan Release, Purification, and Labeling Strategies for HTP

Frequently Asked Questions (FAQs)

Q1: What are the primary strategies for releasing N-glycans from glycoproteins in a high-throughput setting? The two primary strategies are enzymatic and chemical release. For N-glycans, enzymatic release using PNGase F is the most common and efficient method in high-throughput workflows [29] [11]. It cleaves the bond between the glycan and the asparagine residue of the protein, preserving the glycan structure with a free reducing end for subsequent labeling [29]. For O-glycans, chemical release via hydrazinolysis is often used, but it has major drawbacks, including the use of toxic and explosive anhydrous hydrazine and the risk of a "peeling" reaction that can degrade the glycan structure [29]. Enzymatic options for O-glycan release are limited to specific core structures [29].

Q2: Which glycan labeling strategy is best for my high-throughput analysis? The choice of label depends heavily on your detection and separation platform. The following table summarizes common labels and their applications:

Table 1: Common Fluorescent Labels for High-Throughput Glycan Analysis

| Label | Charge | Primary Applications | Key Features |

|---|---|---|---|

| 2-AB (2-Aminobenzamide) [29] [11] [30] | Neutral | HILIC-UPLC/FLDCite | Lacks negative charges; widely used with extensive HILIC databases for structural assignment. |

| 2-AA (2-Aminobenzoic acid) [29] | Negative (-1) | HPLC, CE, MALDI (positive & negative mode) | Versatile; suitable for both neutral and sialylated glycans. |

| APTS (1-Aminopyrene-3,6,8-trisulfonic acid) [29] [11] | Negative (-3) | Capillary Gel Electrophoresis with LIF (CGE-LIF) | Carries strong negative charge; ideal for multiplexed CGE systems analyzing 48-96 samples in parallel [11]. |

| PA (2-Aminopyridine) [29] | - | HPLC Profiling | Requires recrystallization before use due to purity issues; has established databases for structural assignment. |

Q3: My glycan labeling efficiency is low. What could be the cause? Low labeling efficiency can stem from several factors:

- Insufficient label concentration: The concentration of the labeling agent should typically be 0.25 M or greater [29].

- Inefficient reducing agent: While sodium cyanoborohydride (NaCNBH₃) is widely used, it is toxic. 2-picoline borane has been demonstrated as an efficient, non-toxic alternative with equal efficacy [29].

- Incomplete purification: Excess salts, detergents, or proteins from the release step can inhibit the labeling reaction. Ensure proper cleanup of released glycans using solid-phase extraction (SPE) tips, magnetic beads, or 96-well filter plates before labeling [31] [11].

Q4: How can I minimize sample loss during the cleanup and purification of released glycans? High-throughput workflows address this by using tip-based or plate-based solid-phase extraction (SPE) methods. These include:

- C18 Tips: For cleaning up permethylated glycans or intact glycopeptides [31] [32].

- Porous Graphitic Carbon (PGC) Tips: For purifying native glycans [31].

- Hydrophilic Interaction Liquid Chromatography (HILIC) Tips/Magnetic Beads: For purifying fluorescently labeled glycans [11] [3]. These methods are amenable to automation with multichannel pipettes or liquid handling robots, significantly reducing manual handling and improving reproducibility [31] [10].

Q5: I am getting high variability in my quantitative glycan profiling. How can I improve reproducibility? To ensure robust and reproducible data in large-scale studies:

- Use an Internal Standard: For Mass Spectrometry analysis, employ a full glycome internal standard approach. This involves spiking samples with a library of isotopically labeled glycans, which corrects for ionization fluctuations and significantly improves quantitative precision [3].

- Automate Sample Preparation: Utilize 96-well plates and liquid handling robots to process many samples under identical conditions, minimizing analyst-to-analyst and inter-batch variation [10] [30].

- Validate Your Workflow: Perform robustness testing (e.g., using a Plackett-Burman experimental design) to identify critical steps that contribute most to variability. Also, conduct between-day and between-analyst validation to ensure long-term reproducibility [33] [30].

Troubleshooting Guide

Table 2: Common Experimental Issues and Proposed Solutions

| Problem | Potential Causes | Recommended Solutions |

|---|---|---|

| Incomplete Deglycosylation [10] | - Protein not fully denatured- Insufficient enzyme | - Ensure thorough denaturation with detergents (e.g., SDS) and reducing agents (e.g., TCEP) [31].- Increase enzyme-to-substrate ratio or incubation time. |

| Poor MS Signal for Sialylated Glycans [32] | - Loss of sialic acids during analysis- Poor ionization | - Stabilize sialic acids by permethylation or esterification [32] [34].- Use labels like 2-AA that are compatible with negative-mode MS [29]. |

| High Background Noise in Chromatography/Electropherograms [11] | - Inadequate removal of excess fluorescent label | - Optimize the post-labeling cleanup step (e.g., HILIC purification on a 96-well plate or using SPE tips) [11] [3]. |

| Inconsistent Results in a 96-Well Plate [30] | - Edge effects in the plate- Pipetting errors | - Use a randomized sample layout on the plate to avoid position-specific artifacts [30].- Implement automated liquid handling to improve pipetting precision [31] [10]. |

Experimental Protocols for High-Throughput Glycan Analysis

Protocol 1: High-Throughput N-Glycan Release and 2-AB Labeling for UPLC Analysis This protocol is adapted for processing samples in a 96-well plate format [11] [30].

- IgG Isolation: Isolate IgG from plasma or serum using a 96-well protein G plate [30].

- Denaturation: Denature the glycoprotein in the plate using a buffer containing SDS.

- Enzymatic Release: Release N-glycans by adding PNGase F directly to the solution in each well. Incubate for 3-18 hours [11] [30].

- Labeling: Transfer the released glycans to a new plate. Add the labeling mixture containing 0.25 M 2-AB and the reducing agent (sodium cyanoborohydride or 2-picoline borane). Incubate at 65°C for 2 hours [29] [30].

- Cleanup: Purify the labeled glycans using a HILIC-based 96-well filter plate to remove excess dye and salts [11].

- Analysis: Analyze the glycans by HILIC-UPLC with fluorescence detection [30].

Protocol 2: Rapid Permethylation for MS-Based Profiling This microscale protocol is suitable for high-throughput structural characterization in 96-well plates or microcentrifuge tubes [32].

- Glycan Release: Release N-glycans from your glycoprotein sample using PNGase F.

- Microscale Permethylation: Perform permethylation directly in a 96-well plate using a NaOH/ DMSO slurry and methyl iodide. The small reaction volume and plate format allow parallel processing of many samples [32].

- C18 Tip Cleanup: Stop the reaction and purify the permethylated glycans using a C18 tip-based cleanup. This short process removes reaction salts and solvents [32].

- MS Analysis: Dissolve the glycans in MS-compatible solvent and analyze by automated tandem ESI-MSⁿ for in-depth structural characterization [32].

Protocol 3: High-Throughput Glycan Profiling via MALDI-TOF-MS with Internal Standards This protocol emphasizes speed and quantification for quality control scenarios [3].

- Glycan Release: Release N-glycans from biologics (e.g., monoclonal antibodies) in a 96-well plate.

- Prepare Internal Standards: Generate a full glycome internal standard library from a control sample via reductive isotope labeling. This can be automated on a liquid handling workstation [3].

- Sample Purification: Mix the internal standard with your experimental samples. Purify and enrich the combined glycans using Sepharose HILIC SPE in a 96-well plate, which is more amenable to automation than cotton HILIC tips [3].

- Rapid MS Analysis: Spot the samples onto a MALDI target plate. Acquire spectra for hundreds of samples within minutes using MALDI-TOF-MS [3].

- Data Processing: Use automated data processing software to quantify each native glycan based on the ratio of its signal intensity to that of its corresponding internal standard [3].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for High-Throughput Glycomics

| Reagent / Material | Function | Application Example |

|---|---|---|

| PNGase F [29] [11] | Enzymatically releases N-linked glycans from glycoproteins. | Core step in nearly all N-glycan analysis workflows. |

| 2-Picoline Borane [29] | Non-toxic reducing agent for reductive amination. | Safer alternative to sodium cyanoborohydride for fluorescently labeling glycans. |

| CL-4B Sepharose Beads [3] | Hydrophilic matrix for solid-phase extraction (SPE) of glycans. | Used in 96-well plate-based HILIC purification for high-throughput MALDI-TOF-MS workflows. |

| Magnetic Beads (Carboxyl-coated) [11] | Solid support for capturing and purifying released glycans. | Enable rapid, automatable sample preparation by capturing glycans via ionic interaction. |

| Full Glycome Internal Standard [3] | Isotopically labeled glycan library for quantification. | Spiked into samples for precise relative and absolute quantification in MS analysis. |

| C4 / C18 / MAX-Tips [31] | Micro-solid phase extraction tips for clean-up. | Used for desalting, enrichment of intact glycopeptides (C18/MAX), or on-tip protein digestion (C4). |

Workflow Diagrams for High-Throughput Glycomics

The following diagrams illustrate two common high-throughput workflows for glycan analysis.

Diagram 1: HTP Glycan Profiling via HILIC-UPLC.

Diagram 2: HTP Glycan Screening via MALDI-TOF-MS.

FAQs: Integrating MALDI-TOF-MS and UHPLC for Glycomics

Q1: How can I address peak broadening in my UHPLC system when analyzing released glycans?

Peak broadening in UHPLC can severely impact resolution, which is critical for separating complex glycan mixtures. The causes and solutions are multifaceted [35]:

- Blocked frits or particles on column head: Replace the pre-column frit. If fronting returns quickly, investigate the source of particles (sample, eluents, pump mechanics, injection valve).

- Extra-column volume too large: Use short capillary connections with an inner diameter of 0.13 mm (0.005 in.) for UHPLC columns. The extra-column volume should not exceed 1/10 of the smallest peak volume.

- Detector cell volume too large: The flow cell volume should not exceed 1/10 of the smallest peak volume. Use a smaller volume flow cell (i.e., micro or semi-micro) with UHPLC or microbore columns.

- Column degradation: Replace the column. To prevent this, avoid high temperatures in combination with aggressive buffers and operate columns at less than 70-80% of the pressure specification.

Q2: What are the primary considerations for ensuring quantitative accuracy in high-throughput MALDI-TOF-MS glycomics?

The primary challenge for quantitative MALDI-TOF-MS in quality control has been quantitative accuracy and reproducibility. An effective solution is the full glycome internal standard approach [27]. This method involves:

- Generating a broad-coverage N-glycan internal standard library via a one-step process of glycan reduction and isotope labeling, resulting in internal standards with a mass 3 Da higher than their native counterparts.

- Mixing this library with analytical samples. Because the library and native N-glycans share identical compositions and similar relative abundances, quantification accuracy is significantly enhanced.

- Adopting high-throughput purification using Sepharose HILIC SPE in a 96-well plate format instead of Cotton HILIC SPE, enabling full automation on a liquid handling robotic workstation and processing of at least 192 samples simultaneously [27].

Q3: Why does my UHPLC method show high sensitivity to minor retention time shifts, causing resolution failure?

UHPLC's high efficiency means smaller peak widths, which places higher demands on the reproducibility of retention times and selectivity [36].

- A very small change in relative retention (e.g., ~2.5%) can cause a drastic reduction in resolution (e.g., ~50%).

- This occurs because resolution is proportional to (alpha - 1)/alpha, and at high plate counts, the required alpha value to maintain a given resolution is smaller. Therefore, even minor variations in selectivity have a magnified effect on resolution [36].

- Solution: During method development, target higher resolution values (e.g., Rs >= 3) to build in a robustness factor that accommodates minor batch-to-batch variations in sorbents or instrument performance [36].

Q4: How do I manage back pressure issues in my UHPLC system during long glycan analysis batches?

A gradual pressure increase is normal, but a sudden high pressure indicates a blockage [37].

- Isolate the blockage: Progressively loosen fittings starting from the column outlet, then the column inlet, in-line filter inlet (if used), and pump outlet, recording the pressure after each step to find the source [37].

- Most common cause: A blocked in-line frit or guard column frit, which accumulates debris. Use a 0.2-µm porosity in-line frit (for ≤2-µm columns) placed just downstream from the autosampler. This frit is easier and less expensive to replace than the analytical column [37].

- If the column frit is blocked: Back-flush the column by reversing its direction and pumping 20–30 mL of mobile phase to waste. This is effective about one-third of the time. Check the column specifications to see if it can be safely reversed for extended use [37].

Q5: What is a major advantage of using superficially porous particle (SPP) columns for high-throughput UHPLC?

SPP columns, such as Raptor series columns, are made with silica particles that have a solid core and a porous outer layer [38]. They provide [38]:

- Higher efficiency and resolution, often approaching that of smaller (e.g., 1.9 µm) fully porous UHPLC particles.

- The ability to be operated at high flow rates without a significant loss of resolution.

- High-resolution separations on a regular HPLC system without requiring higher-pressure UHPLC system components.

Troubleshooting Guides

UHPLC Pressure Problems

| Symptom | Possible Cause | Solution |

|---|---|---|

| Pressure Too High | Blocked in-line filter or guard column | Replace the in-line filter frit or guard column [37]. |

| Blocked column frit | Back-flush the column (reverse direction) and flush with 20-30 mL mobile phase to waste [37]. | |

| Blocked tubing or other hardware | Sequentially disconnect fittings to isolate the blocked component; replace blocked tubing [37]. | |

| Pressure Too Low | Air in the pump | Open the purge valve and flush with 5-10 mL of mobile phase [37]. |

| Leak or faulty check valve | Check for leaks, ensure fittings are tight. Verify pump check valve function [37]. | |

| Pressure Cycling/Erratic | Leak upstream of the pump | Check the mobile phase reservoir and solvent inlet lines for leaks or obstructions [35]. |

| Failing pump seal | Inspect and replace the pump seal if necessary [35]. |

MALDI-TOF-MS and UHPLC Peak Anomalies

| Symptom | Possible Cause | Solution |

|---|---|---|

| Peak Tailing | Basic compounds interacting with silanol groups | Use a high-purity silica (Type B) or a shielded phase column (e.g., Raptor ARC-18) [35] [38]. |

| Insufficient buffer capacity | Increase the buffer concentration [35]. | |

| Peak Fronting | Column overload | Reduce the amount of sample injected or use a column with a larger internal diameter [35]. |

| Sample dissolved in strong solvent | Re-dissolve the sample in the starting mobile phase or a weaker solvent [38] [35]. | |

| Broad Peaks | Extra-column volume too large | Use shorter, narrower internal diameter capillary connections (0.13 mm for UHPLC) [35]. |

| Detector cell volume too large | Use a flow cell with a smaller volume (micro or semi-micro) for UHPLC columns [35]. | |

| Unexpected/Extra Peaks | Carryover from previous injection | Extend the run time or flushing gradient. Flush the column with a strong eluent at the end of the run [35]. |

| Sample degradation | Use appropriate sample storage conditions and a thermostatted autosampler [35]. | |

| Low Intensity/No Peaks (MALDI) | Analyte loss during sample prep | Ensure proper glycan purification and enrichment. Use internal standards to monitor recovery [27]. |

| Non-ideal matrix:analyte ratio or crystallization | Optimize matrix concentration and sample deposition method to ensure homogeneous co-crystallization [39]. |

Integrated Platform Troubleshooting Logic

Experimental Protocols

High-Throughput N-Glycan Sample Preparation for MALDI-TOF-MS

This protocol is adapted from the high-throughput glycosylation screening method validated for therapeutic proteins like trastuzumab, enabling processing of 192 samples in a single experiment [27].

Workflow Overview:

- Protein Denaturation and Digestion: Denature the glycoprotein sample, reduce disulfide bonds, and alkylate cysteine residues. Use PNGase F to enzymatically release N-glycans from the glycoprotein.

- Internal Standard Preparation: Prepare the full glycome internal standard library via a one-step reductive isotope labeling reaction. This generates isotope-labeled glycans with a mass 3 Da higher than native glycans [27].

- Purification and Enrichment (Sepharose HILIC SPE):

- Perform in a 96-well plate format using CL-4B Sepharose beads for higher throughput and compatibility with automation [27].

- Mix the released glycan sample with the internal standard library.

- Condition the Sepharose HILIC material with organic solvent.

- Load the glycan/internal standard mixture.

- Wash with organic solvent to remove contaminants.

- Elute glycans with an aqueous buffer.

- Sample Spotting and Analysis:

- Vacuum-dry the eluted glycans at room temperature for enhanced stability [27].

- Mix the purified glycan sample with an appropriate MALDI matrix (e.g., DHB).

- Spot onto a MALDI target plate.

- Analyze by MALDI-TOF-MS.

High-Throughput Glycan Prep Workflow

System Suitability and Method Robustness Testing for UHPLC

This protocol is critical for validating UHPLC methods in glycomics, given the technique's sensitivity to minor variations [36].

Procedure:

- Column Performance Verification:

- Test at least three different column batches from the same manufacturer using a standardized test mixture.

- Calculate efficiency (plate count, N), asymmetry factor (As), and retention time reproducibility for key analytes.

- Resolution Robustness Assessment:

- For a critical peak pair, calculate the resolution (Rs) achieved on each column batch.

- Determine the allowable variation in selectivity (alpha) that would cause Rs to drop from the target value (e.g., 2.5) to the minimum acceptable value (e.g., 1.5). As a guide, for UHPLC, this allowable delta can be as small as 0.010 alpha units [36].

- Instrument Parameter Verification:

- Confirm gradient delay volume and composition accuracy.

- Verify dwell volume consistency, as this can significantly impact retention times and selectivity in gradient elution [36].

- Method Adjustment Strategy:

- Based on the results, define allowable adjustments within the method (e.g., minor changes to gradient time or temperature) to compensate for column-to-column variability while maintaining system suitability [36].

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function/Application in High-Throughput Glycomics |

|---|---|

| Sepharose CL-4B Beads | Used in "Sepharose HILIC SPE" for high-throughput purification and enrichment of glycans in a 96-well plate format, replacing traditional cotton HILIC SPE [27]. |

| Full Glycome Internal Standard Library | A collection of isotope-labeled glycans used for precise relative quantification in MALDI-TOF-MS, correcting for run-to-run variability [27]. |

| Raptor Biphenyl Column | A superficially porous particle (SPP) UHPLC column providing high-efficiency separations with performance approaching sub-2µm particles, but without requiring extreme UHPLC pressures [38]. |

| Raptor ARC-18 Column | A C18 column with a sterically protected bonded phase, offering an extended operating pH range (1.0–8.0). Particularly useful for analyzing acids and bases at low pH [38]. |

| 0.2 µm In-line Filter Frit | Placed downstream of the autosampler to capture particulate matter and protect the analytical column from blockage, a common cause of high backpressure [37]. |

| Uracil | An unretained compound used to experimentally determine the void volume (V0) of a reversed-phase LC column [38]. |

| 2,5-Dihydroxybenzoic Acid (DHB) | A common MALDI matrix used for the analysis of carbohydrates and glycans [39]. |

Automated Data Processing and Glycoinformatic Tools for Rapid Interpretation

Technical Support Center

Frequently Asked Questions (FAQs) and Troubleshooting Guides

Q1: Our automated glycan identification software is failing to correctly identify monoisotopic peaks and charge states. What could be causing this and how can we resolve it?

A: This is a common frustration in automated glycomics data analysis. The issue often stems from algorithms that are not fully optimized for the complex isotope patterns of glycans.

- Troubleshooting Steps:

- Manual Verification: Start by manually verifying a subset of your data in the vendor software to confirm the expected monoisotopic masses and charge states. This establishes a ground truth [40].

- Software Settings: Check the software's parameter settings for peak picking and charge state determination. Adjust the parameters for signal-to-noise ratio, isotopic pattern matching, and allowed mass error to be more or less stringent based on your instrument's performance [6].

- Tool Validation: Consider using a tool like GlycoGenius, which was specifically developed to address these challenges by employing algorithms tailored to reduce manual workload and accurately annotate monoisotopic peaks and charge states [40] [6].

- Data Quality Check: Ensure your raw data is of high quality. Poor signal or high background noise can significantly impact automated peak detection.

Q2: We are processing large datasets from LC-MS experiments and the analysis is cumbersome, requiring interfacing between multiple non-integrated software tools. Is there a more streamlined solution?

A: Yes, the lack of integration is a known bottleneck. An optimal solution is a platform that combines data processing, visualization, and analysis within a single interface.

- Troubleshooting Steps:

- Workflow Mapping: Document all the steps and software tools in your current workflow to identify the key points of friction and data transfer.

- Integrated Platform Evaluation: Explore integrated platforms like GlycoGenius or the GRITS Toolbox. GlycoGenius, for example, offers a unified graphical interface that guides users from raw data to publication-ready figures, automating the construction of search spaces, identification, scoring, and quantification [6]. The GRITS Toolbox also provides functionalities for data loading, visualization, annotation, and management of meta-data [41].

- Automation Features: Look for features such as batch processing of multiple samples, automated generation of identification and quantification tables, and built-in data visualization tools to eliminate manual file adjustment between steps [40] [6].

Q3: How can we achieve reliable quantification of glycan isomers that do not co-elute?

A: Accurate isomer quantification requires software that can detect and quantify multiple peaks within the same extracted ion chromatogram (EIC).

- Troubleshooting Steps:

- Chromatographic Separation: First, optimize your LC or CE method to achieve the best possible separation of isomers.

- Software Capability Verification: Confirm that your data analysis software can perform peak detection and integration on traced EICs/EIEs for individual isobaric compounds. Tools like GlycoGenius are specifically designed to detect multiple peaks within a chromatogram and quantify each peak separately, enabling accurate quantification of isobaric compounds that are separated chromatographically [6].

- Internal Standards: Use internal standards for normalization to improve quantification reproducibility across samples [6].

Q4: Our MALDI-TOF-MS glycomics data suffers from poor quantitative reproducibility. What strategies can improve this for high-throughput quality control?

A: The inherent challenges of MALDI-TOF-MS quantification can be mitigated with a robust internal standard strategy.

- Troubleshooting Steps:

- Implement an Internal Standard Method: Adopt a full glycome internal standard approach. This involves generating a library of isotope-labeled glycans that mirror the native glycans in your sample. Each native glycan is quantified relative to its labeled counterpart, which corrects for variations in sample preparation and ionization efficiency [27].

- Automate Sample Preparation: Transfer the sample preparation workflow, including purification and labeling, to a 96-well plate format and use a liquid handling robotic workstation to minimize manual error and improve throughput and consistency [27].

- Data Processing: Utilize automated data processing software that can rapidly handle the data from hundreds of samples, typically providing quantitative results within an hour [27].

Q5: When analyzing glycan microarray data, how can we efficiently manage, process, and interpret the data while complying with reporting standards?

A: Specialized software is essential for handling the complex data and metadata from glycan microarray experiments.

- Troubleshooting Steps:

- Use Dedicated Software: Implement a tool like CarbArrayART. This software is designed for storage, processing, and management of glycan microarray data [42].

- Manage Metadata: Use the software to record all essential metadata compliant with MIRAGE (Minimum Information Required for A Glycomics Experiment) guidelines. This includes detailed information on the glycan probes, array geometry, sample origin, and experimental protocols [42].

- Data Mining: Leverage the software's filtering and sorting functions to interrogate your data based on monosaccharide content or specific glycan motifs (e.g., sialyl linkages) to identify binding patterns [42].

The table below summarizes key software tools for automated glycomics data analysis.

| Tool Name | Primary Function | Technology/Input | Key Features | Availability/Reference |

|---|---|---|---|---|

| GlycoGenius | Automated LC/CE-MS(/MS) data analysis | LC/CE-MS raw data | Automated ID/quantification, GUI, handles N-/O-glycans, GAGs, quantifies isomers [6] | [40] [6] |

| GRITS Toolbox | MS data processing & visualization | MS data | Data annotation, browser, side-by-side experiment comparison, metadata management [41] | [41] |

| GlycReSoft | Single spectra file analysis | MS spectra | Efficient single-spectra analysis, robust quality scoring [6] | [6] |

| CarbArrayART | Glycan microarray data management | Microarray scan files | Data storage/analysis compliant with MIRAGE, heatmap generation, motif filtering [42] | [42] |

| GODDESS | NMR spectrum simulation | Carbohydrate structures | Empirical & statistical 13C/1H NMR prediction, reports expected error [41] | [41] |

| GRASS | NMR-based structure prediction | Unassigned 13C NMR spectrum | Predicts candidate structures from NMR data and constraints [41] | [41] |

| CSDB/SNFG Glycan Builder | Glycan drawing & notation conversion | Graphical user input | Draw glycans, generate SNFG images, 3D models, export to GlycoCT/WURCS [41] | [41] |

Experimental Protocols for High-Throughput Glycomics

Protocol 1: High-Throughput N-Glycan Analysis of Therapeutic Antibodies using MALDI-TOF-MS with a Full Glycome Internal Standard

This protocol is adapted for rapid quality control scenarios, enabling the analysis of 192 samples in a single experiment with high precision (CV ~10%) [27].

Sample Denaturation and Release:

- Transfer a volume of therapeutic antibody (e.g., 10 µL of 1 mg/mL Trastuzumab) to a 96-well plate.

- Denature the protein with a denaturing buffer.

- Use a rapid enzymatic deglycosylation kit (e.g., Rapid PNGase F) to release N-glycans.

Internal Standard Preparation (Full Glycome Library):

- Prepare a separate batch of released glycans from the same or a similar protein.

- In a 96-well plate, subject these glycans to a one-step reductive isotope labeling reaction (e.g., using a reducing agent that adds a 3 Da mass tag).

- Purify the isotope-labeled glycans using a HILIC-based method compatible with 96-well plates, such as Sepharose HILIC SPE.

- Vacuum-dry the internal standard library and store at -80°C.

Sample Labeling and Mixing:

- Label the released glycans from Step 1 with a suitable matrix-friendly tag.

- Mix a known amount of the internal standard library with each experimental sample.

Purification:

- Perform a clean-up step using the 96-well Sepharose HILIC SPE method to remove excess salts and labels.

Data Acquisition:

- Spot the purified glycan-internal standard mixture onto a MALDI target plate with matrix.

- Acquire mass spectra using a MALDI-TOF-MS instrument. Hundreds of samples can be analyzed within minutes.

Automated Data Processing:

- Use automated software to process the spectra.

- The software identifies each native glycan by its paired internal standard, quantifying the relative abundance based on the peak intensity ratio. Results can typically be obtained within an hour [27].

Protocol 2: Automated Identification and Quantification of Glycans from LC-MS Data using GlycoGenius

This protocol outlines a streamlined workflow for going from raw data to quantified glycan lists and figures with minimal manual intervention [6].

Data Input:

- Launch GlycoGenius and create a new project.

- Import the raw data files from your LC-MS or CE-MS instrument.

Library Construction:

- Use the built-in search space creator to define the parameters for your glycan library (e.g., monosaccharide compositions, allowed modifications like sulfation or phosphorylation, reducing-end tags).

- The tool automatically constructs a combinatorial or custom glycan library against which the MS data will be searched.

Automated Processing:

- Run the automated analysis workflow. The software will:

- Identify putative glycan signals in the MS1 data.

- Create extracted ion chromatograms (EICs) for all detected glycans.

- Accurately annotate monoisotopic peaks and charge states.

- Perform deisotoping and adduct deconvolution.

- Quantify peaks by calculating the area under the curve (AUC) for each EIC.

- Apply quality criteria (isotopic distribution fit, peak shape, mass accuracy).

- Run the automated analysis workflow. The software will:

Data Visualization and Verification:

- Use the integrated graphical interface to visualize raw spectra, chromatograms, and annotated EICs.

- Review the automatically generated identification and quantification tables.

Export of Results:

- Export the final results in a human-readable format (e.g., .csv or .xlsx).

- Generate publication-ready figures, including SNFG cartoon representations of the identified glycans [6].

Workflow Visualization for High-Throughput Glycomics

The following diagram illustrates the integrated automated workflow for glycomics data analysis, from sample preparation to biological insight.

Integrated Automated Workflow for Glycomics

The diagram below details the core automated data processing steps within a tool like GlycoGenius.

Automated MS Data Processing Steps

Overcoming Challenges in High-Throughput Glycomics Implementation

Addressing Quantitative Reproducibility with Internal Standard Strategies

Troubleshooting Guides

Guide 1: Addressing Poor Quantification Reproducibility

Problem: High variability in glycan quantification results between sample runs, indicated by high Coefficient of Variation (CV) values.

Explanation: Inconsistent sample preparation, instrument response, or data processing can lead to poor reproducibility. Internal standards correct for these technical variations [43].

Solution: Implement a stable isotopically labeled internal standard.

- Steps:

- Select Appropriate Internal Standard: Choose a (^{13}\text{C})-labeled N-glycan that mimics your target analytes [44] [45].

- Early Introduction: Add the internal standard at the very beginning of sample preparation to account for losses during all subsequent steps [43].

- Consistent Concentration: Ensure the internal standard is added at the same concentration across all samples in the study.

- Data Normalization: Calculate peak area ratios (Target analyte / Internal Standard) for quantification instead of using raw analyte peak areas [43].

Verification: Process six replicate samples. With a proper internal standard, CVs for major glycan species should be ≤12% [27].

Guide 2: Troubleshooting Linearity and Reproducibility Issues in MS Analysis

Problem: Increasing internal standard response with increasing target compound concentration, or general reproducibility issues.

Explanation: This can indicate active sites in the ion source or other instrumental problems that the internal standard cannot fully compensate for [46].

Solution: Systematic instrument diagnostic and maintenance.

- Steps:

- Isolate the Problem Area: Perform a direct injection of calibration standards. If the internal standard area counts increase with concentration, the active site is in the GC-MS (source or inlet liner) [46].

- Clean MS Source: If the problem is isolated to the MS, source maintenance is required [46].

- Check Other Components: If the problem persists after direct injection, investigate the autosampler, purge and trap, or column for issues like leaking drain valves or faulty heaters [46].

Frequently Asked Questions (FAQs)

FAQ 1: What are the key criteria for selecting an effective internal standard for quantitative glycomics?

An ideal internal standard should not be present in the native sample matrix and should behave similarly to the target analytes. For glycomics, this means using isotopically labeled versions of the glycans being studied. Commercially available libraries of high-purity, (^{13}\text{C})-labeled N-glycans are specifically designed for this purpose. The internal standard should be added at a consistent concentration across all samples and at a similar concentration level to the target analytes [44] [43].

FAQ 2: How much can an internal standard improve measurement precision?

The improvement can be substantial. As demonstrated in a GC-FID study, using an internal standard (Hexadecane) reduced the relative standard deviation (RSD) of method precision samples from 0.48% to 0.11%—an improvement factor of 4.4. This enhancement is even more critical for complex sample matrices and trace-level analysis where sample preparation is more challenging [43].

FAQ 3: What level of reproducibility can be expected from a validated high-throughput glycomics method using internal standards?